Equipment for preparing laser plant spore non-oxidation wall-breaking material

A plant spore and material technology, which is applied in the field of equipment for the preparation of laser plant spore non-oxidative wall-breaking materials, can solve the problems of high use and maintenance costs, and achieve the effect of reducing the number of cycles and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

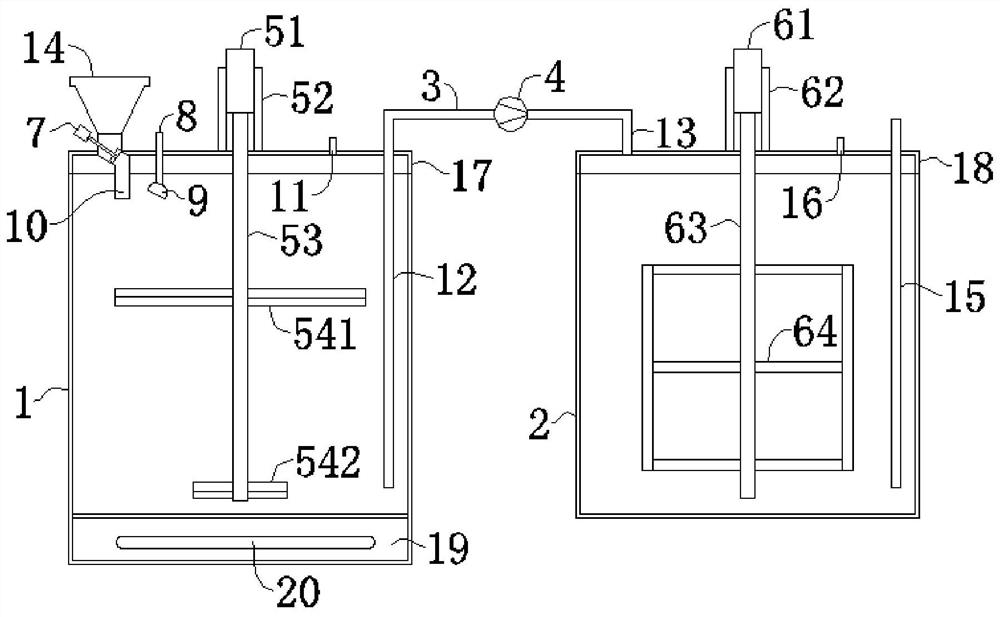

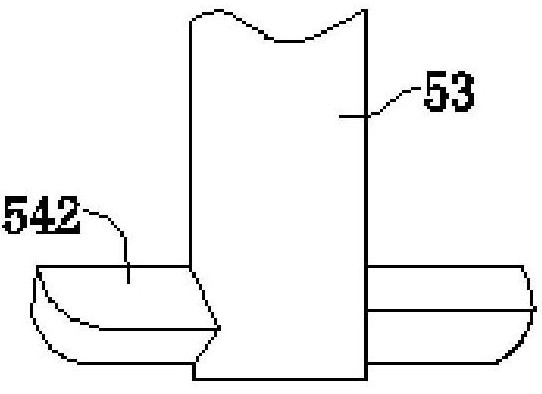

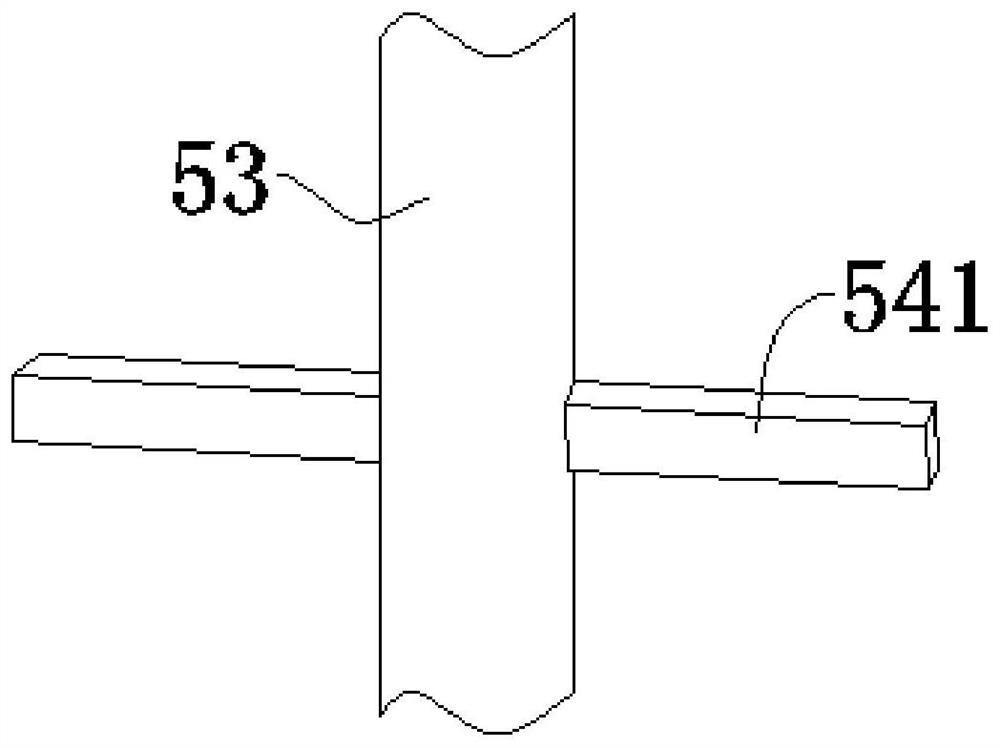

[0043] Example 1: A laser plant spores non-oxidizing material prepared by broken equipment, such as Figure 1-4 , The material comprising a barrel 1, two materials tub 2, the connection pipe 3 and a pump 4. A barrel material and a secondary material 1 tub 2 is connected through the connecting pipe 3, a pump 4 is mounted on the connection pipe 3 and the material for the inner tub 1, a material drawn into the tub 2 two materials. A material barrel 1 and the tub 2 are made of two materials made of 304 stainless steel, and are flat circular pot. The base material 1 a tub 19 provided with a heating chamber, the heating chamber 19 is provided with an electric rod 20, the heating temperature of the heating rod 20 is controlled at 40-50 ℃. A material barrel 1 is provided with a first lid top cover 17, the first lid 17 and the strength of the structure to meet the requirements to ensure that the material can be locked in a barrel 1 closed. A first lid 17 is provided on the spores feed hoppe...

Embodiment 2

[0056] Example 2: A laser plant spores non-oxidizing material prepared by broken equipment as in Example 1 in that the difference, such as Figure 5 , The head 9 is located spores feed pipe 10 side of the inner wall, facing the outlet nozzle 9 discharge spores feed pipe 10 side of the inner wall of the other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com