Automobile sensor assembling device

A technology for automotive sensors and assembly equipment, which is applied in metal processing equipment, chemical instruments and methods, and devices for coating liquid on the surface, etc. It can solve the problems of inaccurate assembly, low assembly efficiency, and poor integrity, and achieve accurate feeding , High feeding efficiency and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

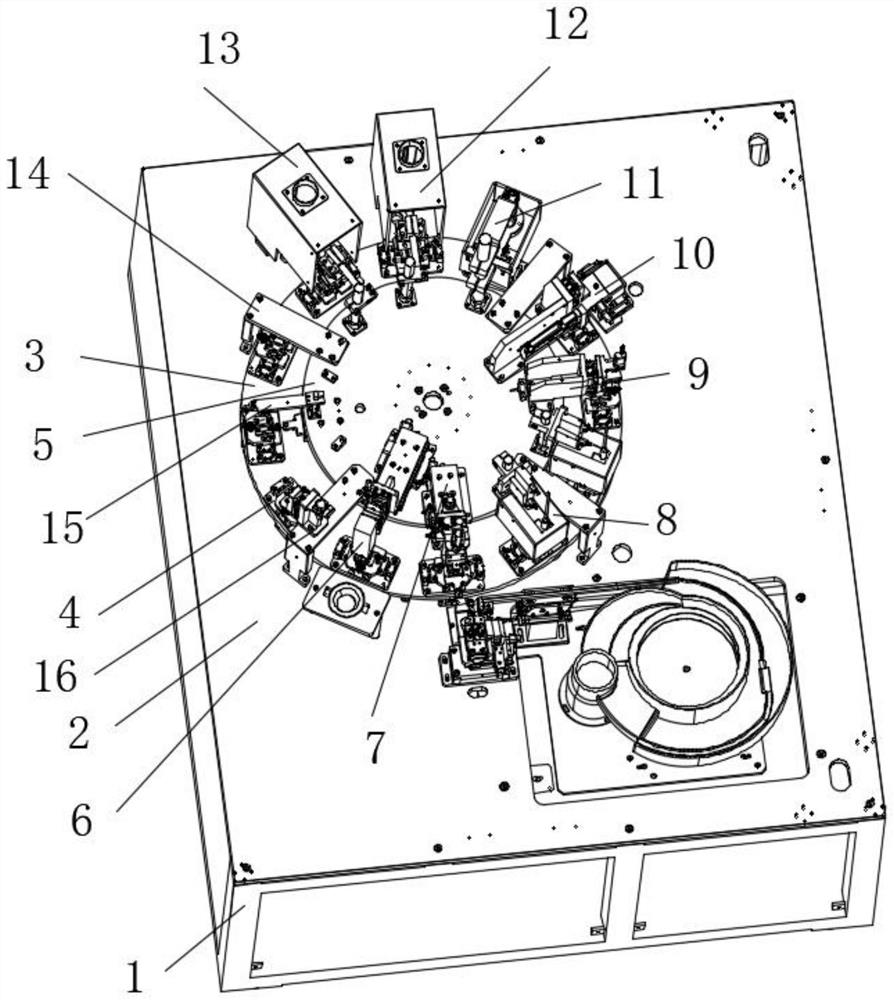

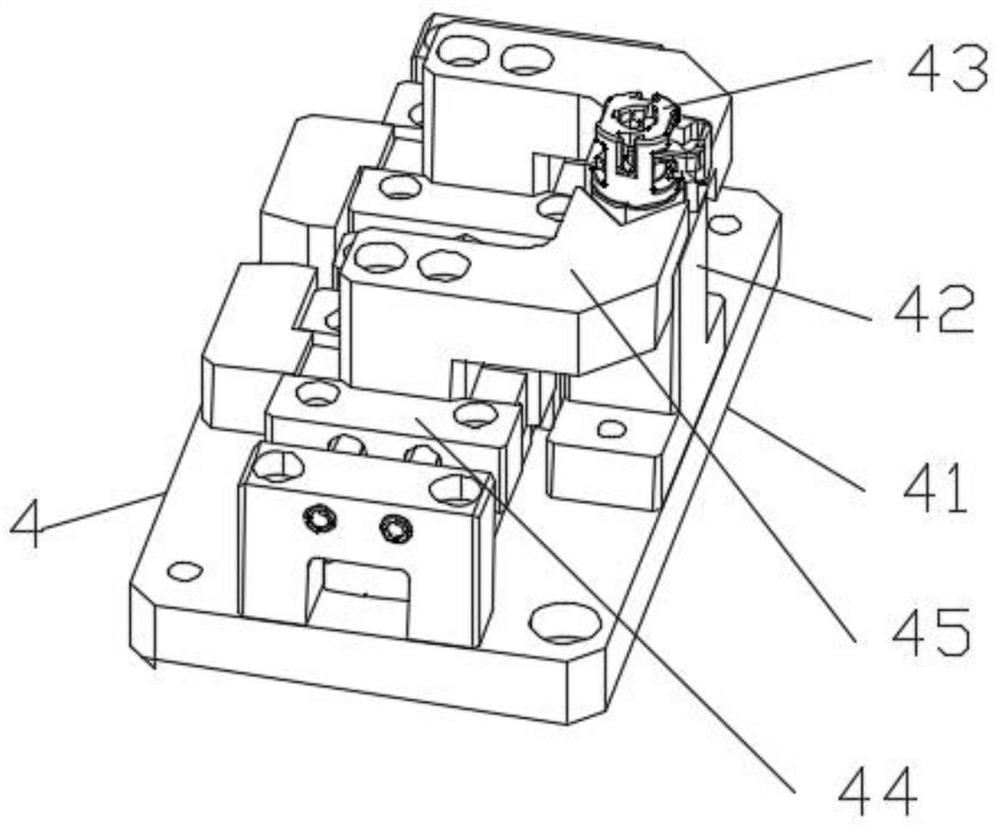

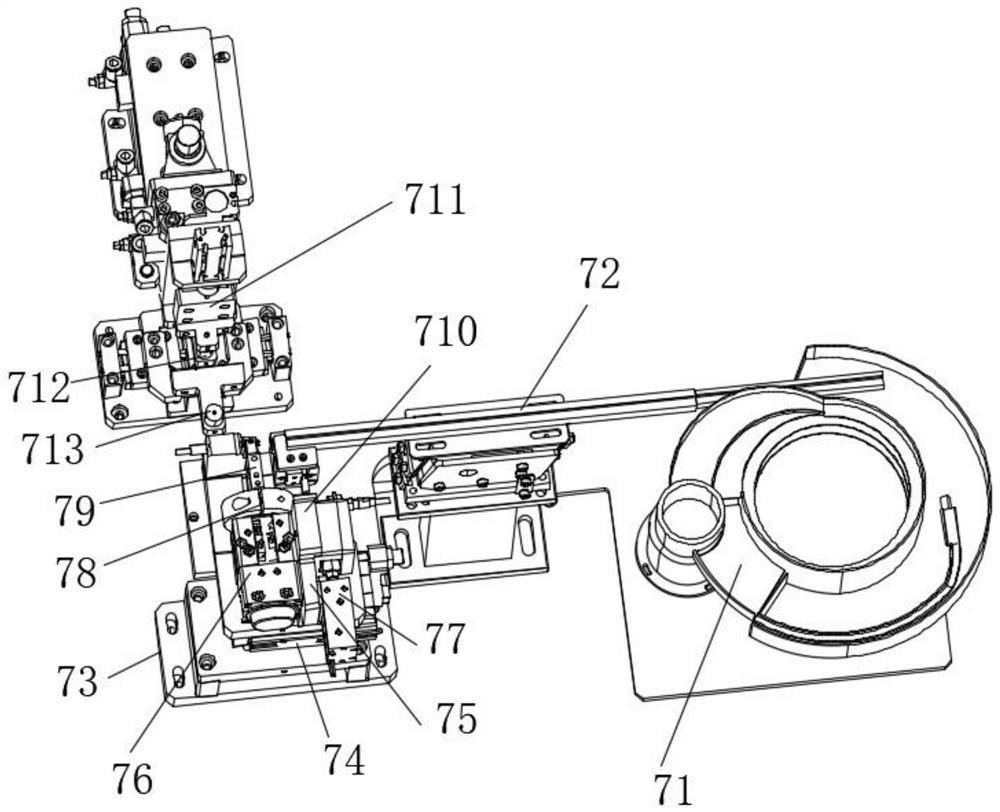

[0016] like Figure 1-2 As shown, a kind of automobile sensor assembly equipment includes: a frame 1, a support platform 3 is installed on the frame 1 through a machine platform 2, and 12 groups of sensor fixing base structures 4 are evenly installed on the peripheral side of the support platform 3 , the sensor fixing base structure 4 includes a base plate 41, the base plate 41 is provided with a sensor support 42, the sensor support 42 is fixed with a sensor 43, and the rear side of the sensor support 42 is provided with 2 sets of clamping The cylinder module 44, the clamping cylinder module 44 is provided with the clamping rod 45 corresponding to the sensor 43, the sensor 43 is clamped by the clamping cylinder module 44, the clamping is stable, the positioning effect is good, and the assembly is stable ;

[0017] One end of the clamping rod 45 close to the sensor 43 is dovetail-shaped, and the clamping rod 45 clamps the sensor's circumference, and the clamping is extremely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com