Universal formwork for forming house prefabricated laminated slab

A technology of prefabricated components and universal moulds, which is applied in the direction of moulds, manufacturing tools, ceramic molding machines, etc., can solve the problems of size deviation and difficulty in achieving consistency of prefabricated components of house prefabricated components, and achieve saving mold processing time, good general performance, The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

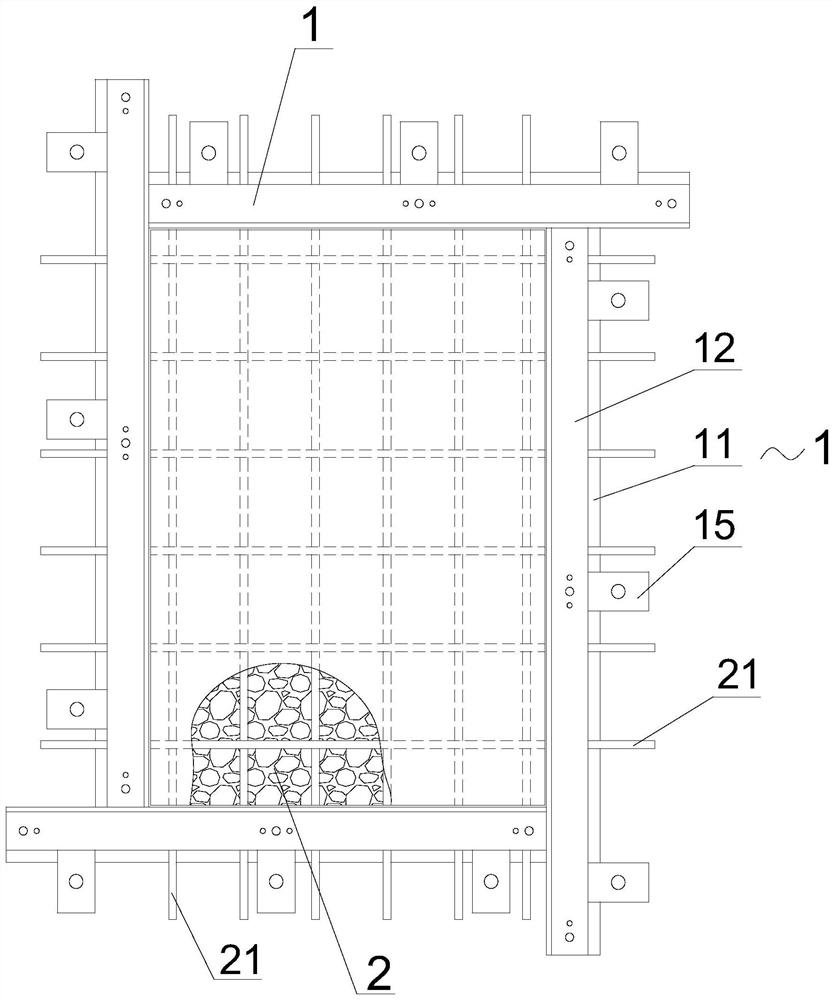

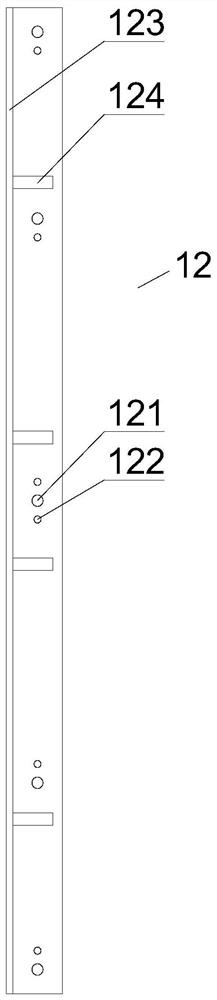

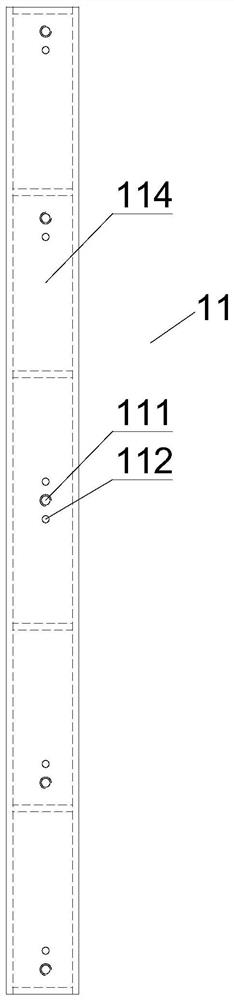

[0041] Such as Figure 1 to Figure 5 As shown, a general mold for forming laminated panels of prefabricated building components includes a plurality of forming side mold assemblies 1 . A plurality of forming side formwork assemblies 1 are used to enclose and form the outer frame of the prefabricated laminated slab bottom plate 2 sequentially according to the design shape of the component. Wherein, the forming side mold assembly 1 is provided with a bottom mold 11 and a side mold 12 . The cross-sectional width of the bottom mold 11 is larger than that of the side mold 12, and the bottom mold 11 is fixedly arranged on the mold platform 3; Gasket 13 and sealing strip 14.

[0042] It should be mentioned that the ends of the criss-crossing steel bars 21 in the prefabricated laminated slab bottom slab 2 protrude from the gap between the bottom form 11 and the side form 12 respectively. The side mold 12, the sealing strip 14 and the inner surface of the bottom mold 11 are in flush...

Embodiment 2

[0055] The difference between embodiment two and embodiment one is that the standard limit block 16 in embodiment two is in the shape of a cuboid, and the length of the standard limit block 16 is 100mm, the width is 50mm, and the thickness is 10mm, and then the standard limit block will be The block 16 plays the role of accurately controlling the molding size of the prefabricated component laminated slab, and makes it necessary to remove the standard limit block 16 first when removing the general mold used for forming the laminated slab of the prefabricated building component, so as to leave enough space for the bottom mold 11 tear down.

[0056]To sum up, the present invention arranges a bottom mold 11 and a side mold 12 that are easy to separate in the forming side mold assembly 1, and an overhead gasket 13 is provided between the bottom mold 11 and the side mold 12, and the prefabricated laminated plate bottom plate 2 The steel bar 21 can protrude from the gap between the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com