Rotation starting separation mechanism

A separation mechanism and screw technology, which is applied in the direction of motor vehicles, space navigation equipment, space navigation aircraft, etc., can solve the problems of harsh weight index and inapplicability of the return cabin, and achieve high separation attitude accuracy, simple structure and low weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

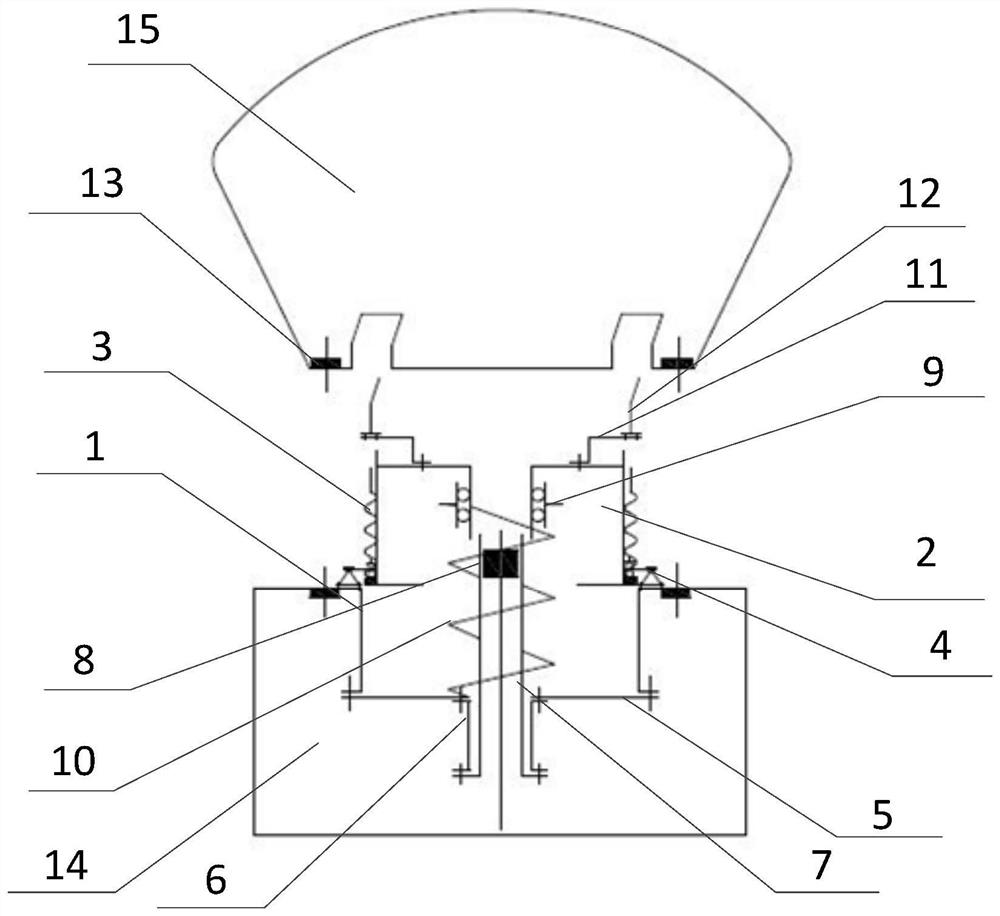

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0033] This embodiment provides a spinning separation mechanism, which is in a compacted state before the task re-entry and return section, and can press the spinning load on the main detector; when it is necessary to re-enter and return the spinning load, it can Provides a stable initial rotational speed for spin-up loads to achieve highly reliable and high-precision spin-off separation.

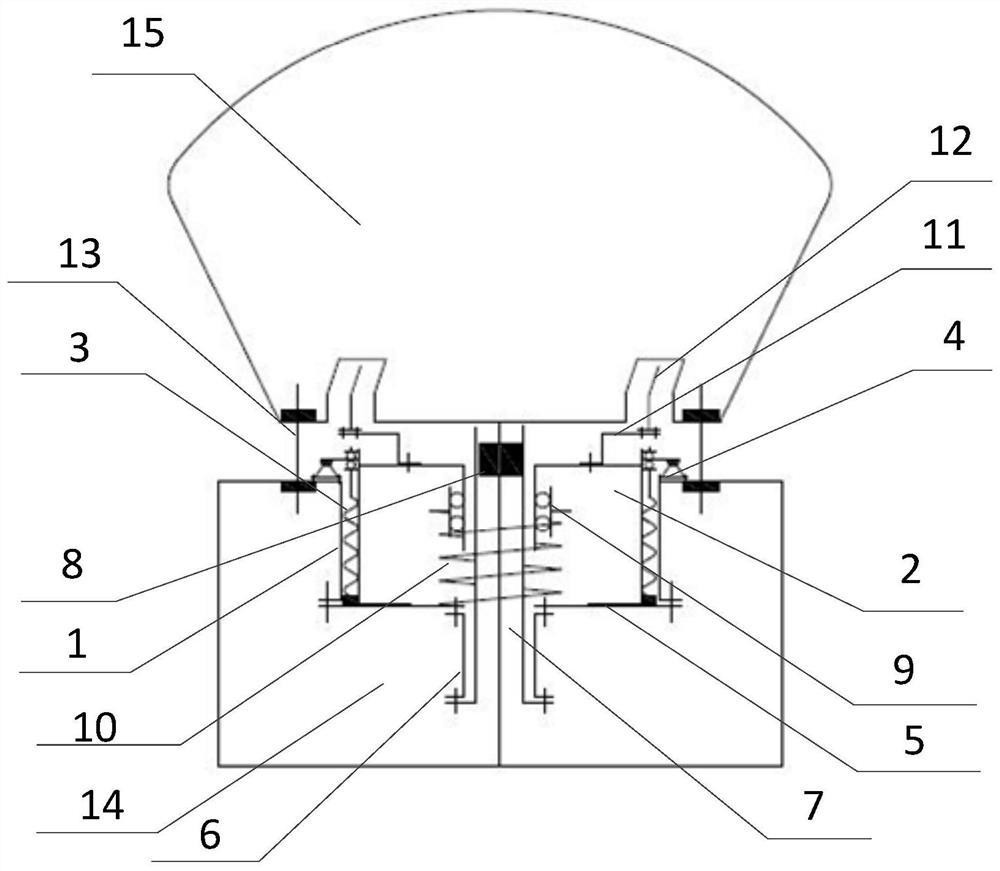

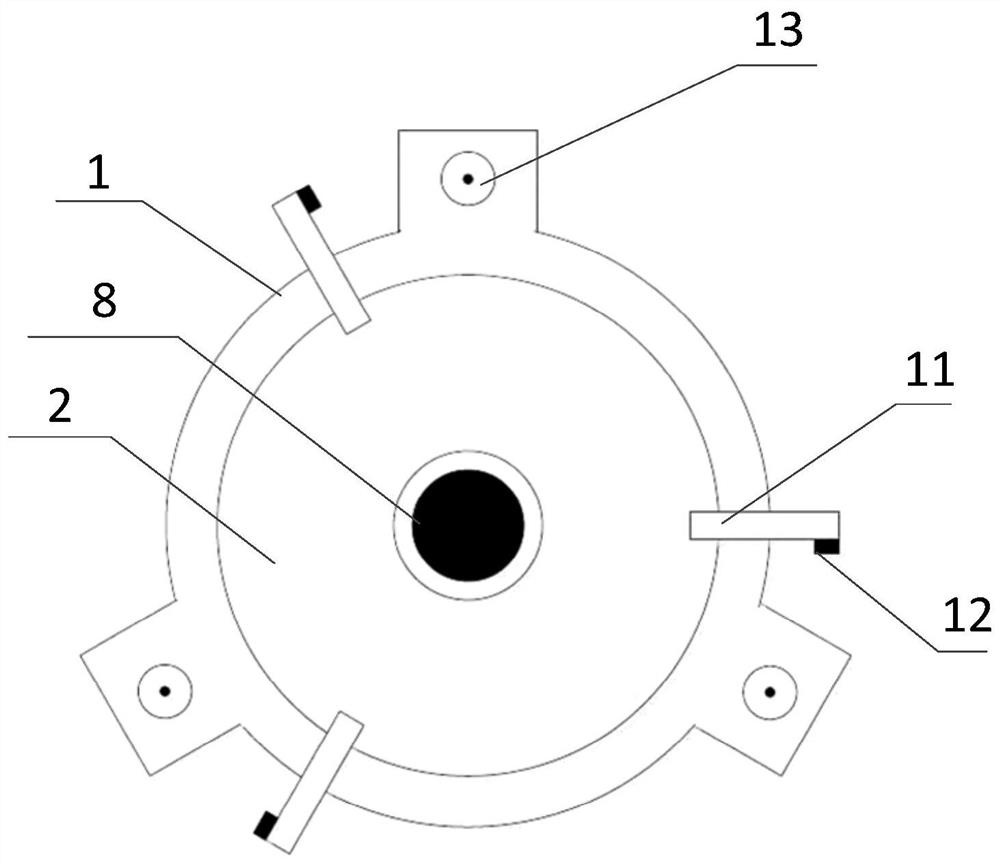

[0034] Such as figure 1 As shown, the spinning and separating mechanism is arranged on the main detector 14 of the deep space probe (relative to the spinning and separating mechanism in this embodiment, the main detector 14 is an external structure), and the main detector 14 is a spinning and separating mechanism. The organization provides the interface;

[0035] The spinning and separating mechanism includes: an outer cylinder 1, a rotating cylinder 2, a spiral chute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com