Bag type grouting soil stress active dynamic control method

A soil stress and dynamic control technology, applied in excavation, soil protection, construction, etc., can solve problems such as damage to adjacent structures, various influencing factors, and deficiencies, so as to improve accuracy, improve flexibility, and avoid excessive correction or The effect of insufficient correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

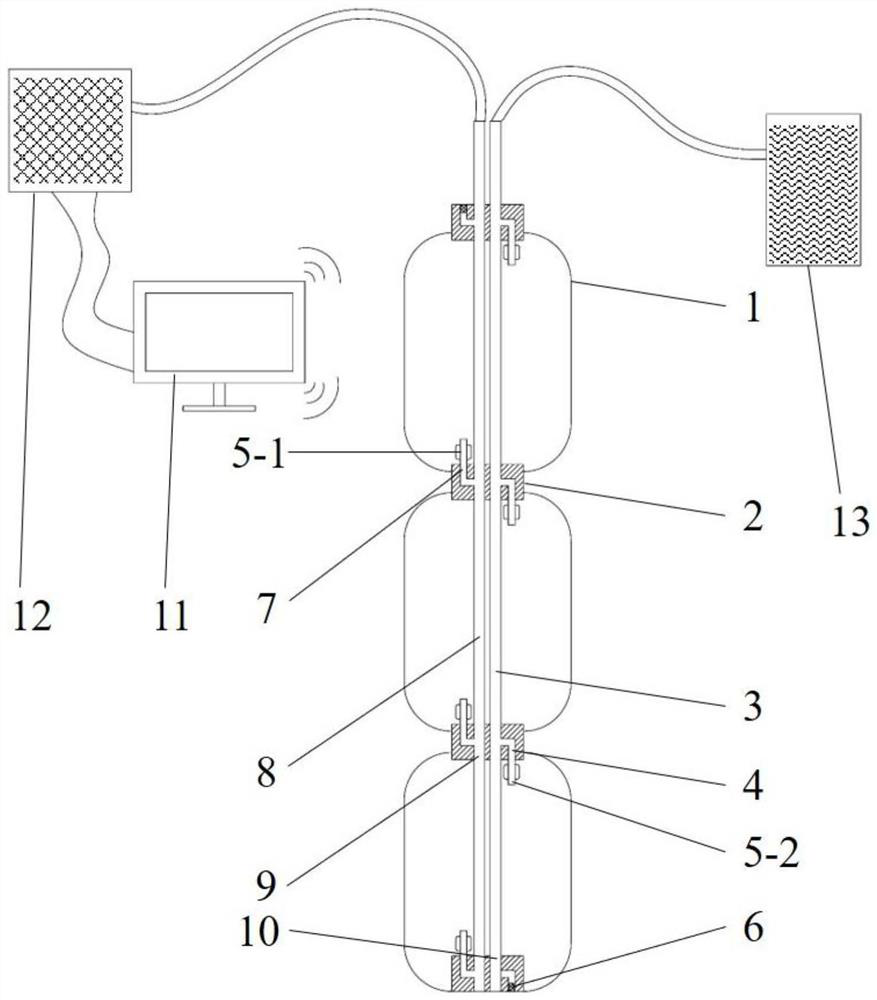

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

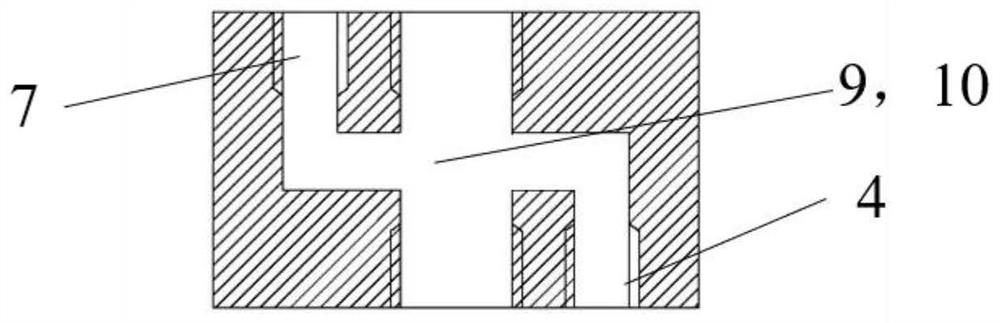

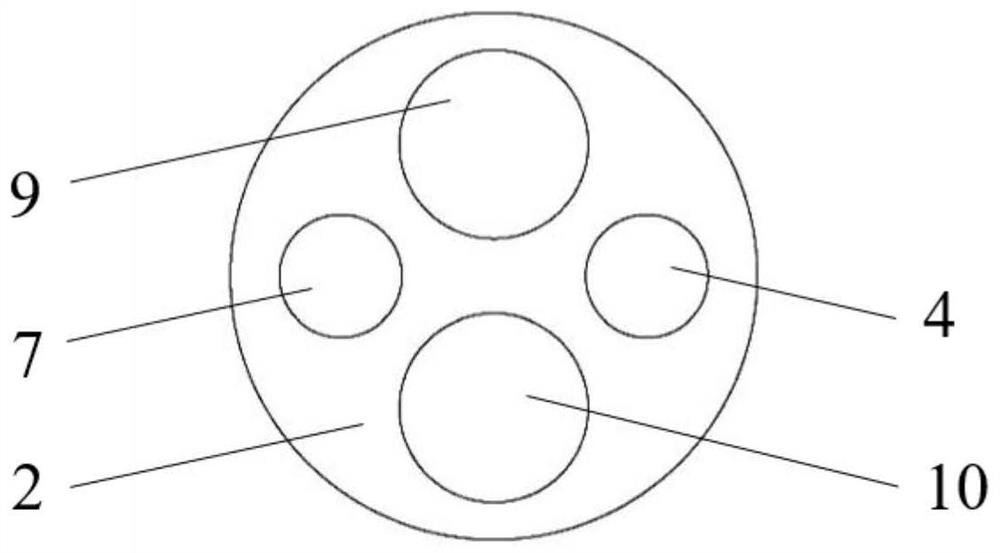

[0016] see Figure 1 ~ Figure 3 , an active and dynamic control method for bladder grouting soil stress, embedding a string of bladders at a setting position, the string of bladders includes a plurality of bladders 1 connected in series, and at both ends of each bladder 1 Each is provided with a joint 2, and a plurality of the bladders 1 are connected in series by parallel grouting pipes 8 and grouting pipes 3, and the grouting pipes 8 and the grouting pipes 3 are connected in sections. Each segment of the pipe joints is connected by a corresponding joint 2. The bottom of the bladder 1 is provided with a grouting pressure solenoid valve 5-1, and the top is provided with a grouting pressure solenoid valve 5-2. The grouting pressure The electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com