Non-contact rotary potentiometer based on light refraction principle

A non-contact, potentiometer technology, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of reducing detection accuracy, increasing the contact resistance of brushes and resistors, and low life, so as to improve detection accuracy, Improve the anti-vibration ability and improve the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

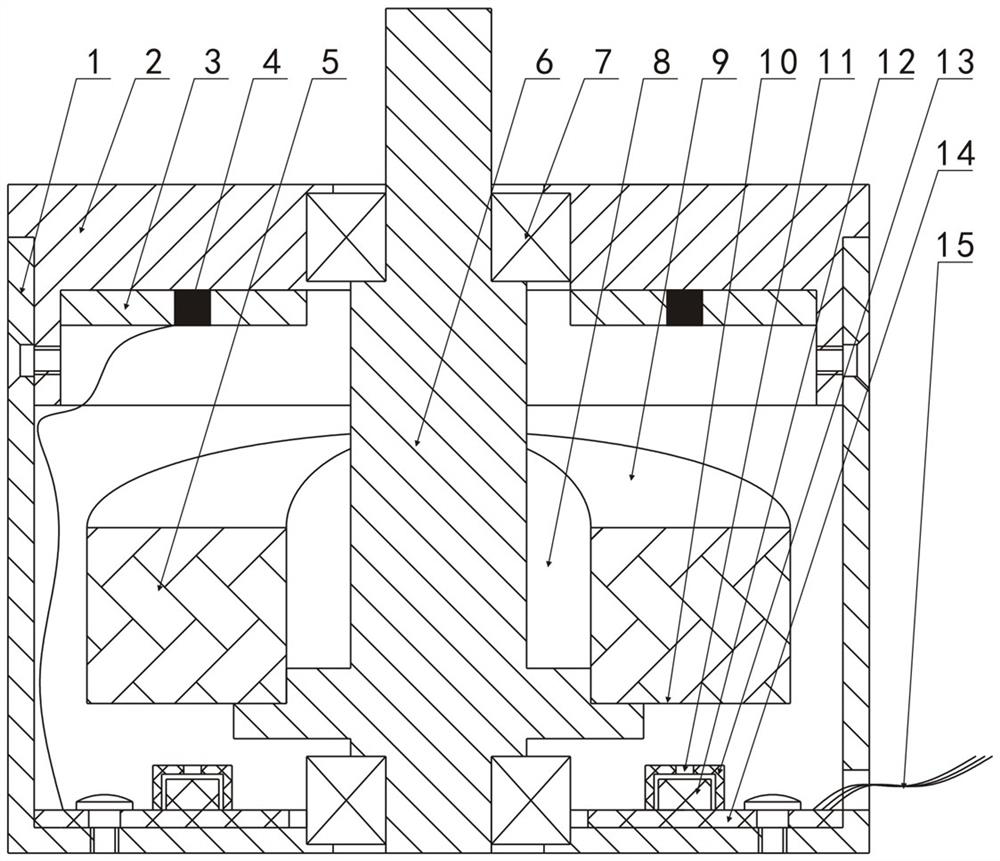

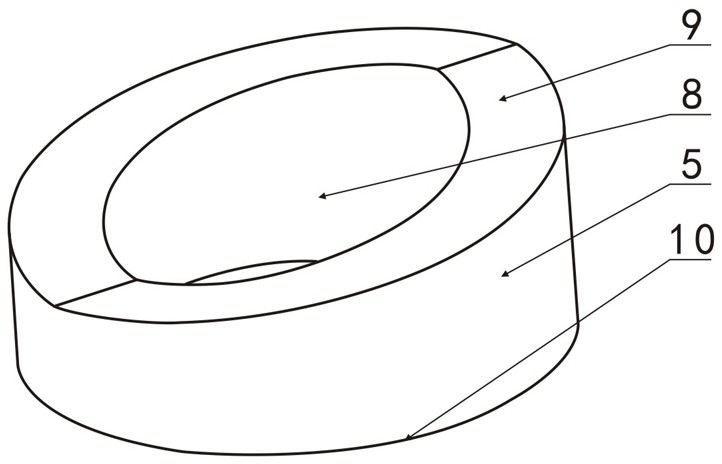

[0033] Such as figure 1 and figure 2 As shown, assume that the light source 4 is located above the refracting lens 5, the photosensitive device 12 is located below the refracting lens 5, the central axis of the refracting lens 5 is vertical, and the lower end surface of the refracting lens 5 is a circular horizontal plane 10. The upper surface of the lens 5 is circular and formed by connecting two symmetrical oblique planes 9 (or arc-shaped surfaces) end to end, that is, using figure 2 In the shown refracting lens 5, the light source 4 is a point light source and is installed on the light-shielding plate 3, the light-shielding plate 3 is installed in the housing, and a light-shielding cover 13 is installed outside the photosensitive device 12, and a light-shielding cover 13 is provided on the upper end of the light-shielding cover 13. Hole 11, in the process of refracting lens 5 rotating 360 °, the outgoing light of light source 4 all can pass through hole 11 of shading cov...

Embodiment 2

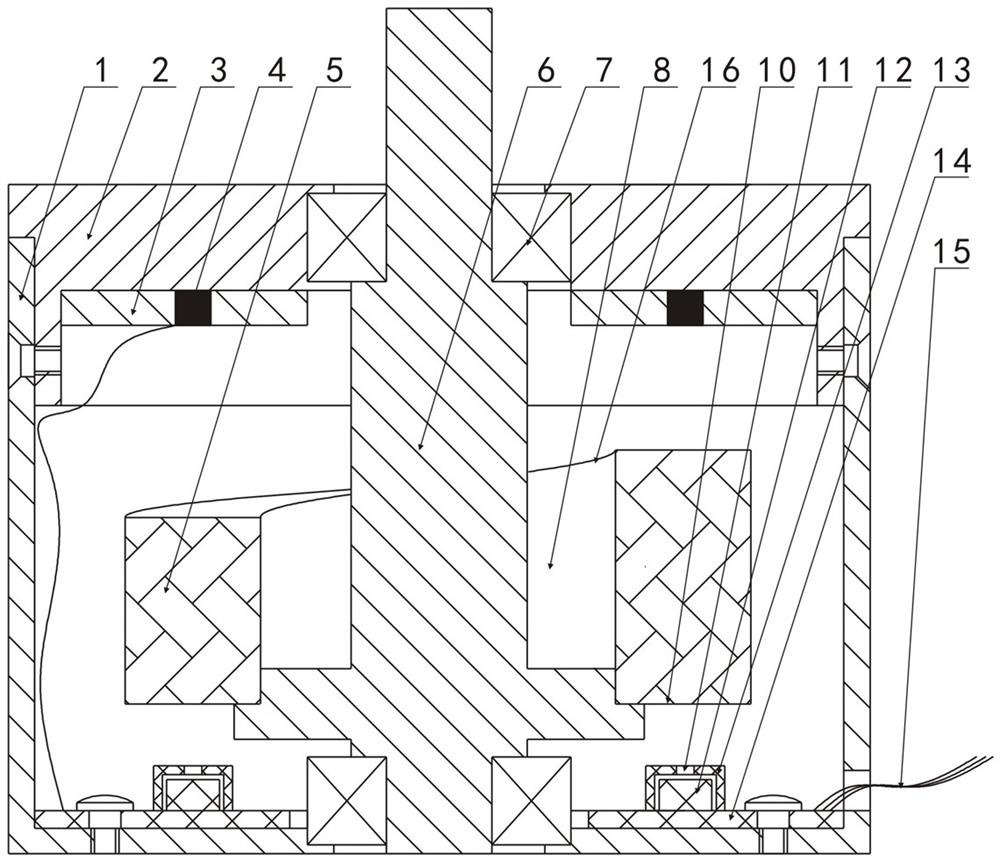

[0036] Such as image 3 and Figure 4 As shown, assume that the light source 4 is located above the refracting lens 5, the photosensitive device 12 is located below the refracting lens 5, the central axis of the refracting lens 5 is vertical, and the lower end surface of the refracting lens 5 is a circular horizontal plane 10. The upper surface of the lens 5 is an integral inclined plane 16 (it can also be an integral arc surface), which gradually rises from one low position to another high position and the low position and high position are located on the same vertical straight line, that is, adopt Such as Figure 4 In the shown refracting lens 5, the light source 4 is a point light source and is installed on the light-shielding plate 3, the light-shielding plate 3 is installed in the housing, and a light-shielding cover 13 is installed outside the photosensitive device 12, and a light-shielding cover 13 is provided on the upper end of the light-shielding cover 13. Hole 11,...

Embodiment 3

[0039] Such as Figure 5 As shown, assume that the light source 4 is located above the refracting lens 5, the photosensitive device 12 is located below the refracting lens 5, the central axis of the refracting lens 5 is vertical, and the lower end surface of the refracting lens 5 is a circular horizontal plane 10. The upper surface of the lens 5 is circular and formed by connecting two symmetrical oblique planes 9 (or arc-shaped surfaces) end to end, that is, using figure 2 In the shown refracting lens 5, the light source 4 is a point light source and is installed on the light-shielding plate 3, the light-shielding plate 3 is installed in the housing, and a light-shielding cover 13 is installed outside the photosensitive device 12, and a light-shielding cover 13 is provided on the upper end of the light-shielding cover 13. Hole 11, in the process of refracting lens 5 rotating 360 °, the outgoing light of light source 4 all can pass through hole 11 of shading cover after being...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com