Thrust detection equipment

A technology of thrust and equipment, which is applied in the field of testing thrust equipment, can solve the problems of inconvenient product traceability, analysis, and poor versatility, and achieve the effects of convenient development and testing, reliable performance, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

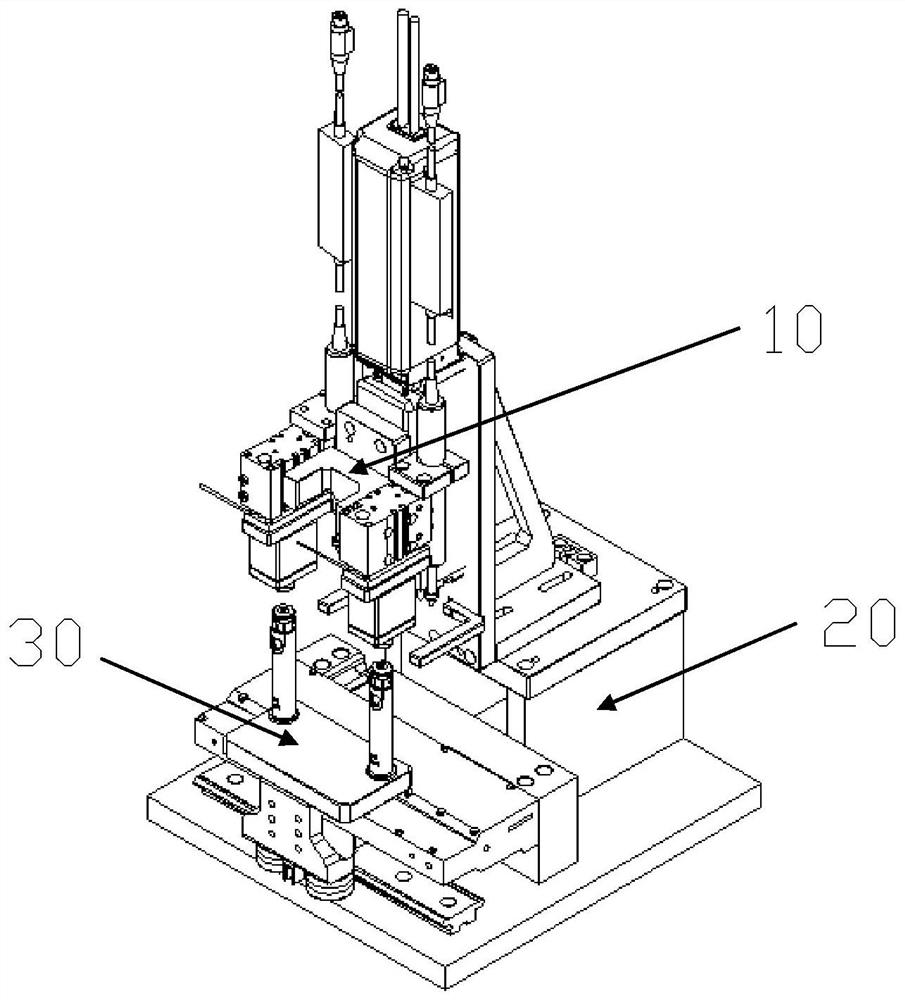

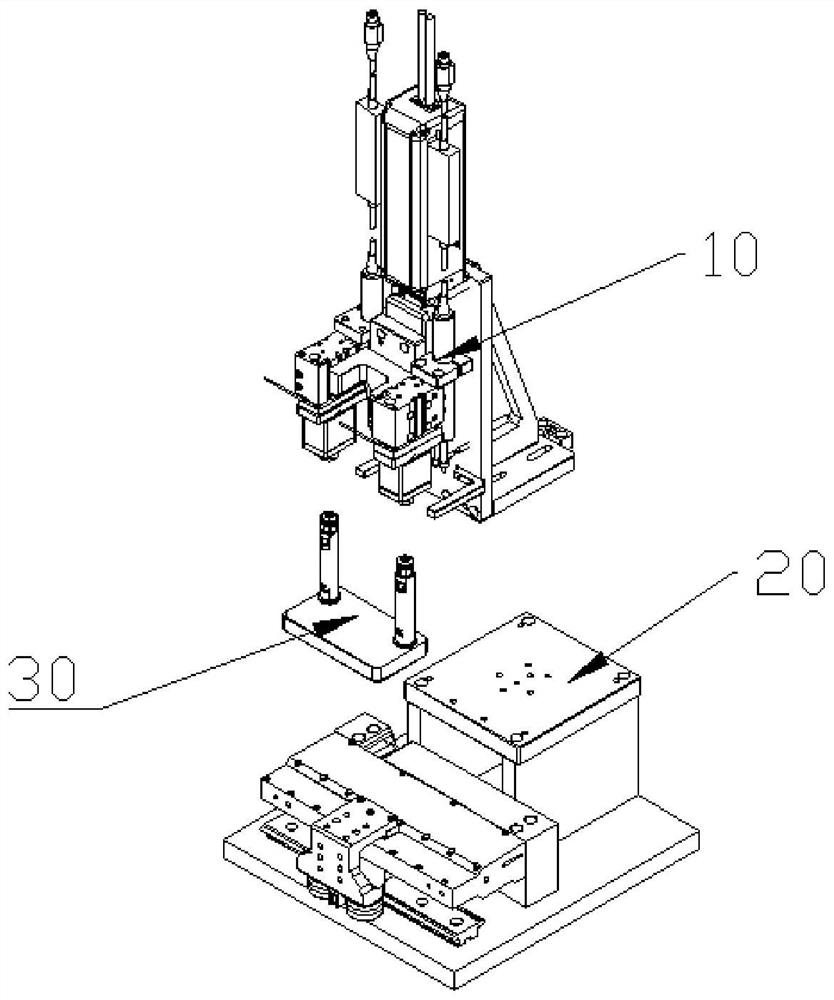

[0021] refer to Figure 1-Figure 5 , a thrust testing device, including a thrust testing mechanism 10, a tooling driving carrier line 20, and a product tooling carrier 30.

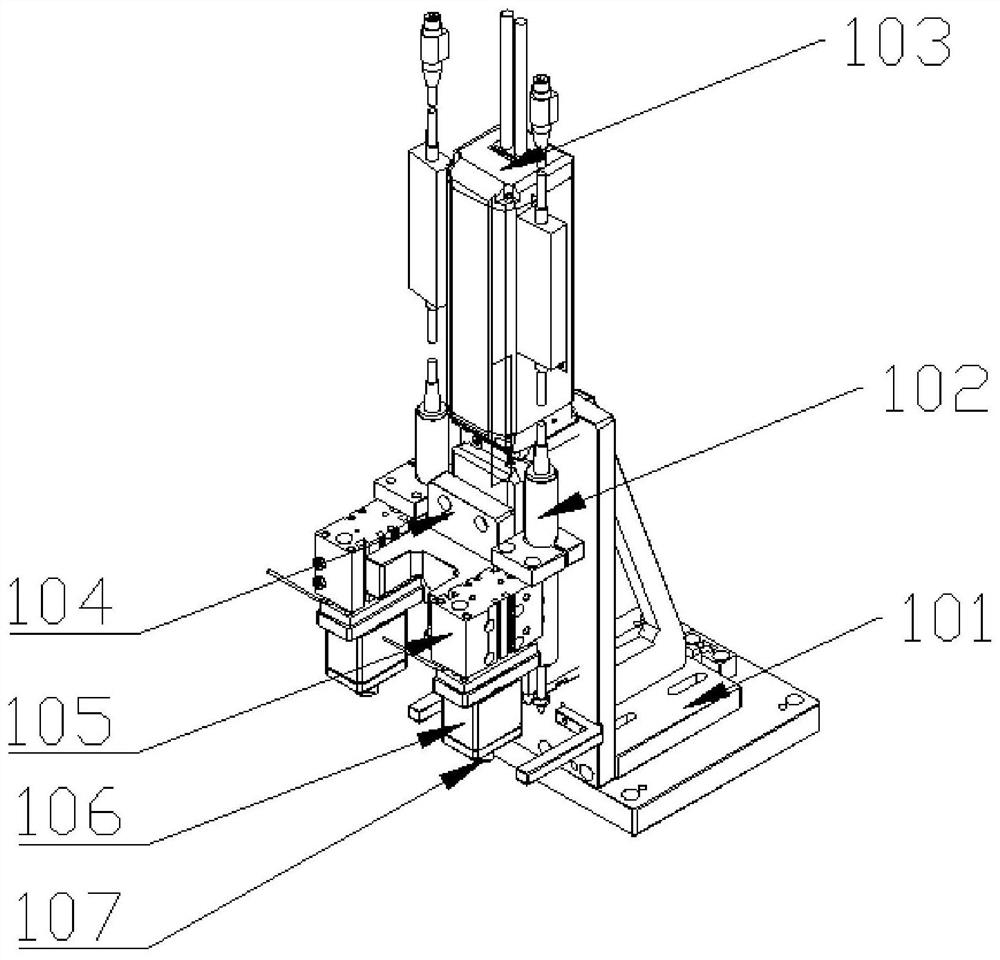

[0022] The thrust test mechanism 10 includes a fixed base 101, a displacement sensor 102, a lifting servo electric cylinder module 103 (ie, the first lifting mechanism), a fixed base 104, a lifting cylinder 105 (ie, the second lifting mechanism), a pressure sensor protective cover 106, a thrust Test head 107. The lifting servo electric cylinder module 103 is fixed on the fixing seat 101, and the lifting electric cylinder 103 is equipped with a fixing seat 104, and the lifting cylinder 105 and the displacement sensor 102 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com