Multipurpose flue gas sampling system

A sampling system and multi-purpose technology, applied in the field of air pollutant control, can solve the problems of inconvenient on-site maintenance, poor adaptability, single function, etc., and achieve good economic use value, good adaptability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

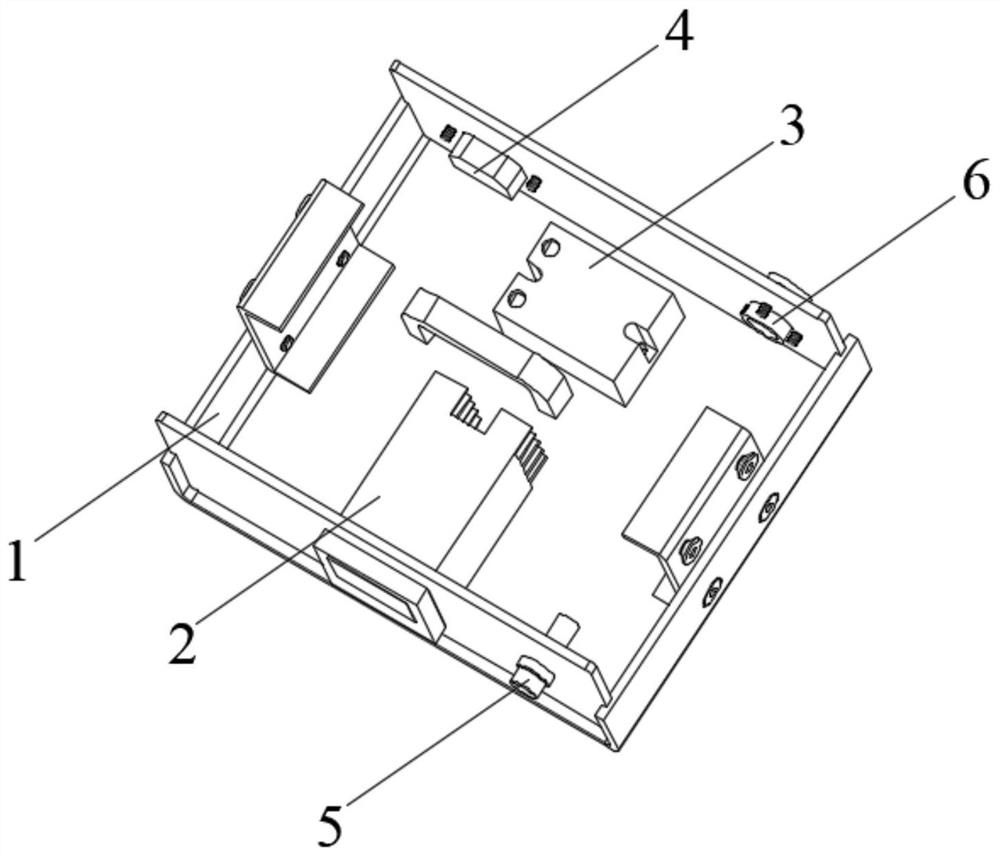

[0028] like Figure 1 to Figure 9 As shown, a multi-purpose flue gas sampling system includes:

[0029] The temperature control device is connected with the sampling device and is used to control the temperature of the sampling device;

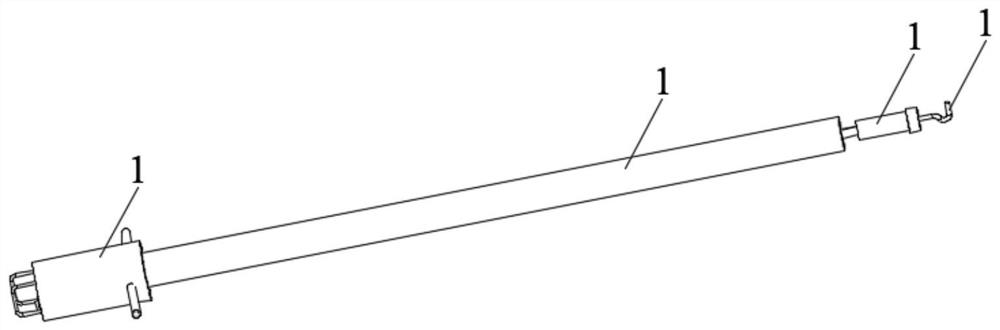

[0030] The sampling device is used for flue gas sampling and temperature detection, and the detected temperature signal is fed back to the temperature control device in real time;

[0031] The sampling device is connected with the sampling device, and is used for receiving the flue gas output by the sampling device, and performing capture tests on the pollutants in the flue gas respectively.

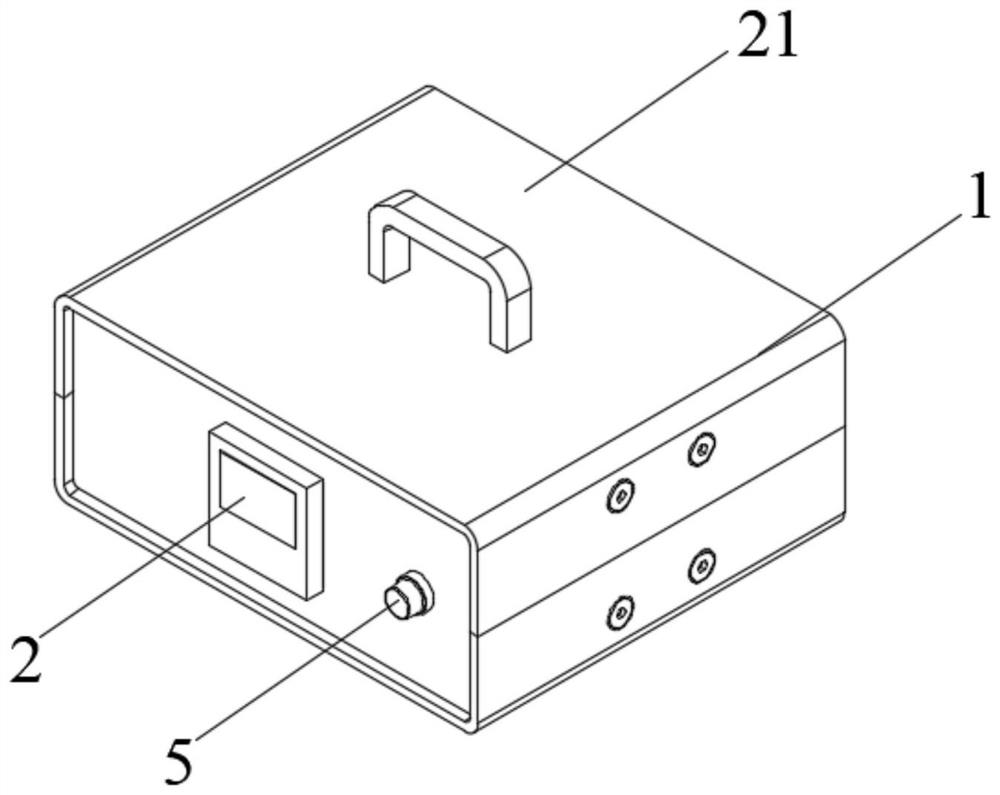

[0032] The temperature control device includes a temperature control box 1, a temperature control instrument 2 installed in the temperature control box 1, a relay 3 connected to the temperature control instrument 2, and a power interface 4, a fuse 5, and a quick interface 6 are arranged on the temperature control box 1 , the power interface 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com