Blast furnace bottom carbon brick automatic generation method and device

A blast furnace, carbon brick technology, applied in the creation/generation of source code, image data processing, special data processing applications, etc., can solve problems such as low efficiency, inaccurate material quantity statistics, and unintuitive two-dimensional drawing technology. The effect of reducing production costs, reducing duplication of work, and improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

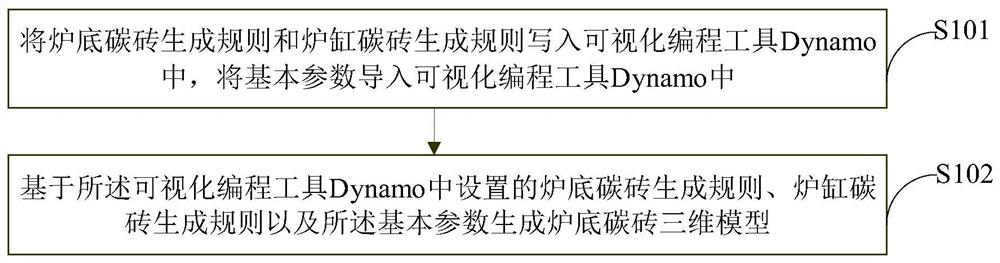

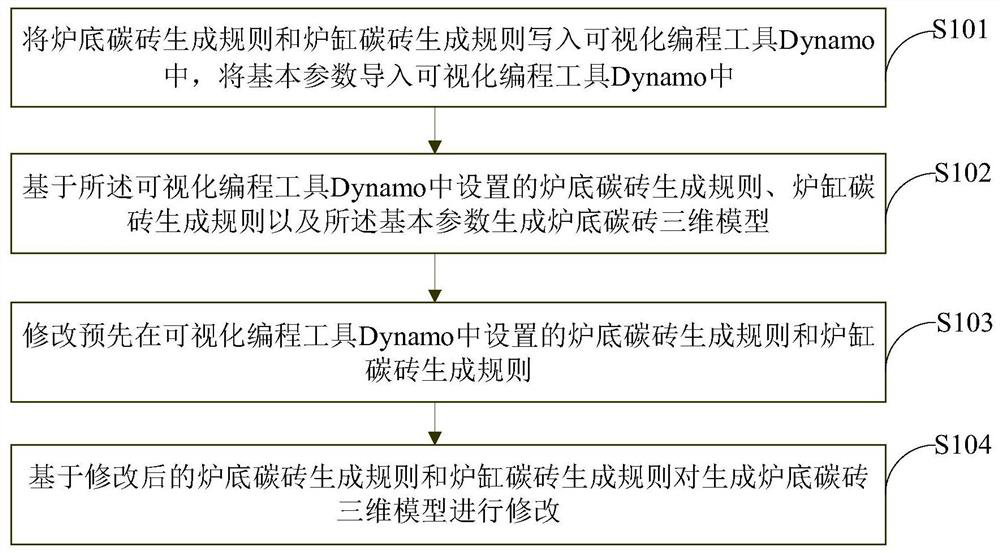

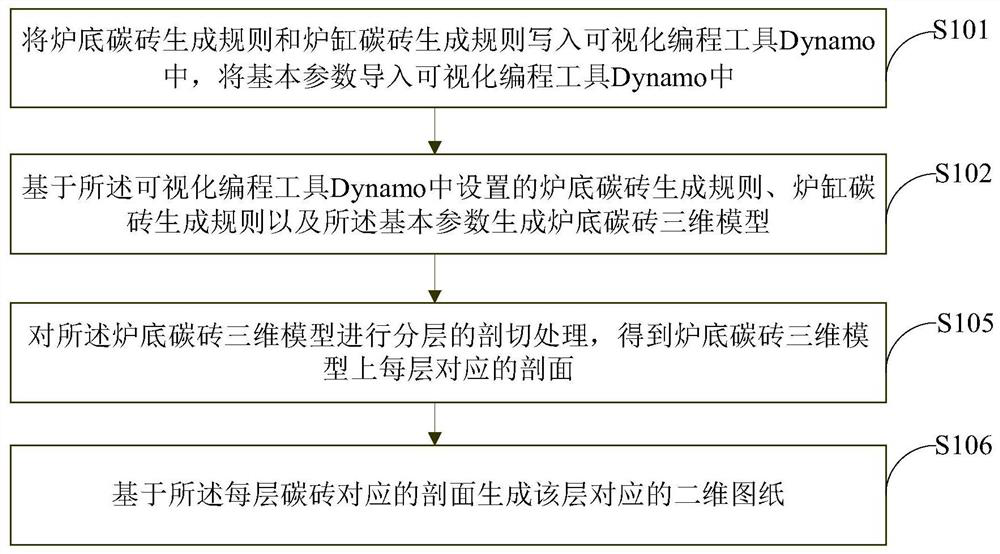

Method used

Image

Examples

Embodiment Construction

[0067] In order to make the objects, technical solutions, and advantages of the present invention more clearly, the technical solutions in the embodiments of the present invention will be described in contemplation in the embodiment of the present invention. It is an embodiment of the invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

[0068] Currently furnace bottom carbon brick still rely on traditional two-dimensional graphics technology, there is the traditional design methods are not intuitive design cycle is long, low efficiency, large brick statistical difficulty of the problem. In order to improve design efficiency, reduce production costs, improve market competitiveness. The present invention provides a furnace bottom carbon blocks automated generation method and apparatus to solve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com