Ultra-high-cycle fatigue life prediction method and device and storable medium

A technology of fatigue life prediction and life prediction model, which is applied in the direction of measuring devices, using repeated force/pulsation force to test the strength of materials, instruments, etc., can solve the problems that the life prediction accuracy of metal materials cannot be guaranteed, and achieve the effect of improving the prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

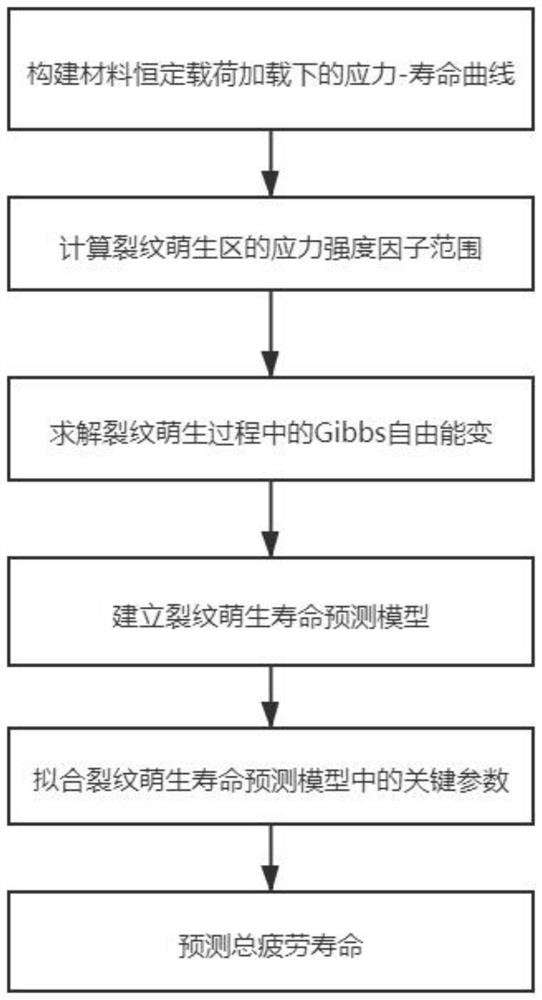

[0088] The embodiment of the present invention discloses a method for predicting the ultra-high cycle fatigue life of metal materials based on the energy method, such as figure 1 shown, including the following steps:

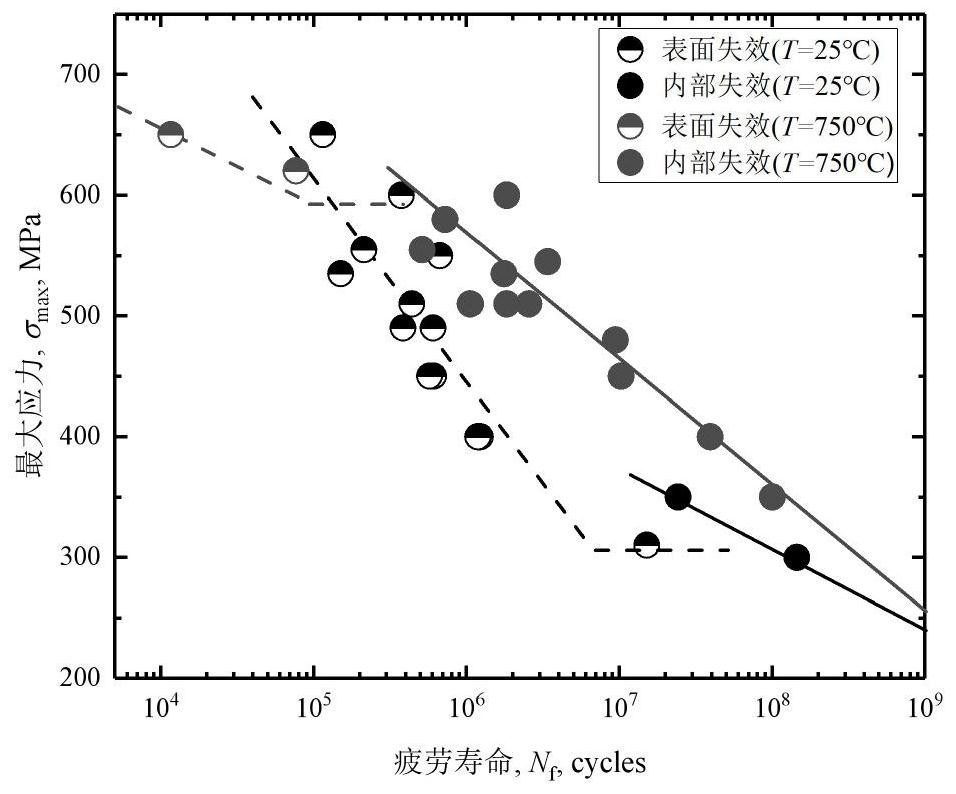

[0089] Conduct fatigue tests on metal materials and construct stress-life curves;

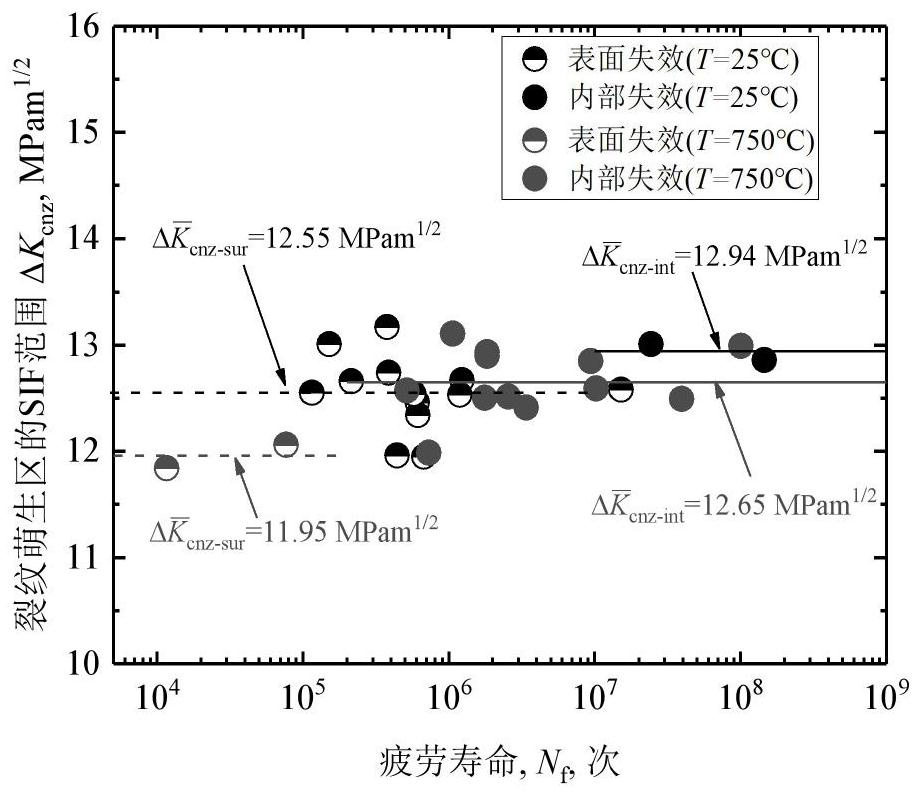

[0090] Measure the characteristic size of the crack initiation zone on the fatigue test fracture, and calculate the stress intensity factor range of the crack initiation zone;

[0091] Based on the fracture mechanics and energy method, the Gibbs free energy change in the process of crack initiation is solved;

[0092] Combined with the strain energy stored in the dislocation dipoles of a single or equivalent slip band, a crack initiation lifetime prediction model is established;

[0093] Combined with the stress-life curve and the characteristic size of the crack initiation zone, the key parameters in the crack initiation life prediction model are fitted;

[0094] The total fa...

Embodiment 2

[0151] The embodiment of the present invention discloses a metal material ultra-high cycle fatigue life prediction device based on the energy method, such as Figure 6 shown, including:

[0152] Obtain a module for constructing the stress-life curve of the material under constant load loading;

[0153] Calculation module, used for calculating the stress intensity factor range of the crack initiation zone;

[0154] The processing module, based on fracture mechanics and energy method, solves the Gibbs free energy change in the process of crack initiation;

[0155] A generating module for establishing a crack initiation life prediction model;

[0156] The training module combines the stress-life curve and the characteristic size of the crack initiation zone to fit the key parameters in the crack initiation life prediction model;

[0157] Prediction module for predicting total fatigue life.

[0158] In one embodiment, a computer storage medium is also provided, on which a comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com