Push-type friction nanometer generator capable of improving low-frequency output

A nano-generator and press-type technology, applied in the direction of friction generators, etc., can solve the problems of being prone to wear, cracking, pollution, and poor durability, and achieve the effects of low production cost, improved service life, and increased frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

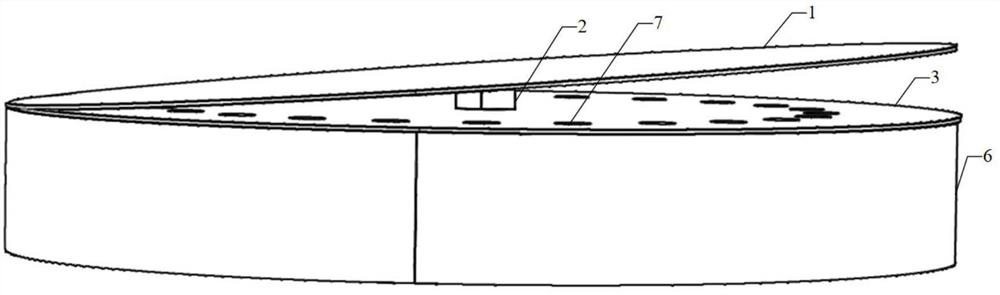

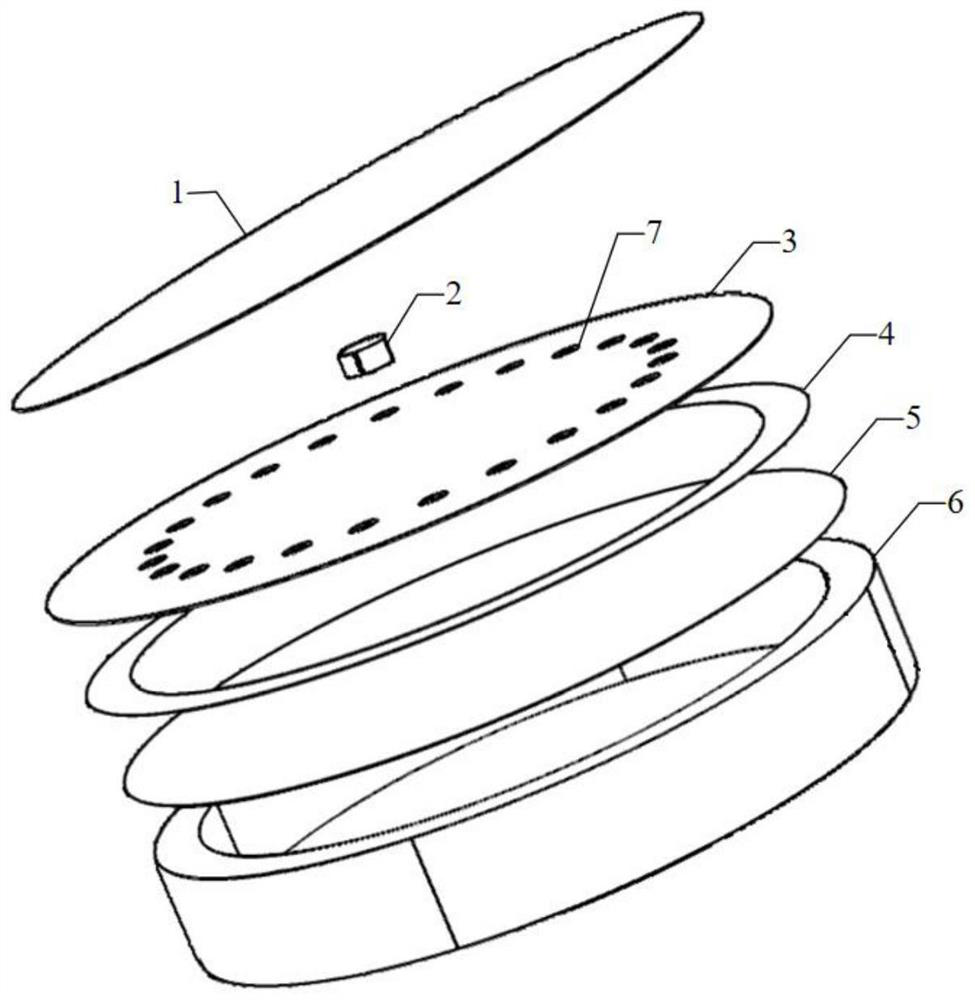

[0061] see figure 1 , which is a schematic diagram of the overall structure of a press-type friction nanogenerator for improving low-frequency output provided by the present invention. The force-bearing surface 1 of the device is a circular spring steel sheet, with a diameter of 80 mm and a thickness of 0.3 mm when it is realized in practice.

[0062] The edge of the spring steel sheet is pasted on the edge of the upper surface of the positive electroconductive plate 3 (this embodiment adopts conductive PLA material, made by 3D printing) toward the center of the circle at about 4mm, and the thickness of the positive electroconductive plate 3 is 0.8mm.

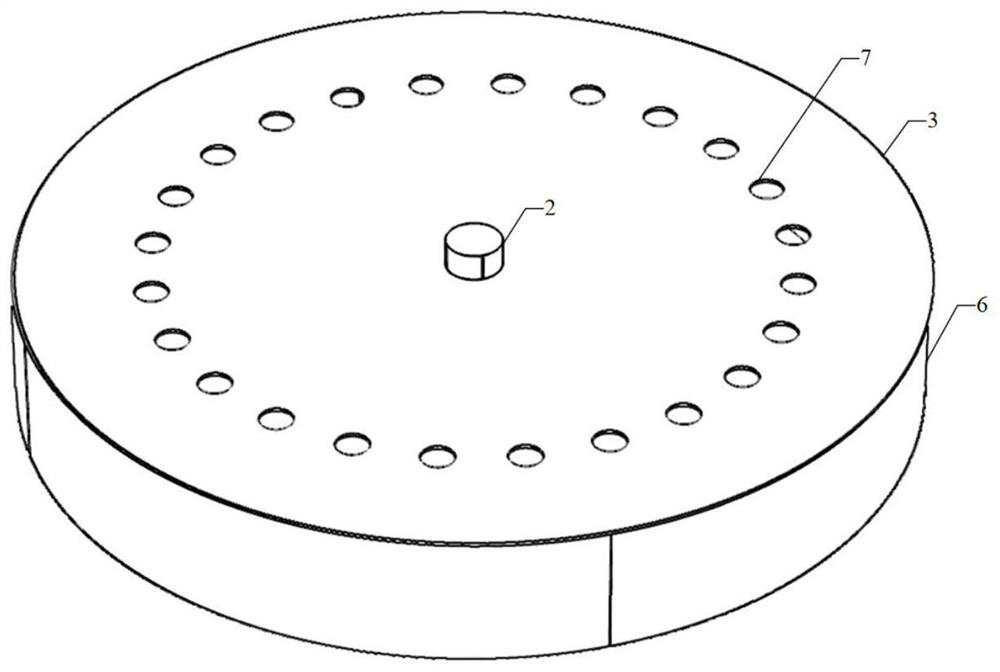

[0063] If the upper circular spring steel sheet 1 is removed, the shape of the device is as follows figure 2 shown. The insulating spacer 2 is 6mm in diameter in this embodiment, 2mm in thickness, and the material is nylon. After it is bonded to the center of the positively conductive plate 3, the spring steel sheet bonded ...

Embodiment 2

[0078] see Figure 19 , which is a schematic diagram of the overall structure of a press-type friction nanogenerator for improving low-frequency output provided by the present invention. The force-bearing surface 1 of the device is a circular spring steel sheet, with a diameter of 80 mm and a thickness of 0.3 mm when it is realized in practice.

[0079] The edge of the spring steel sheet is pasted on the edge of the upper surface of the positively charged conductive plate 3 (the present embodiment adopts a circular spring steel material) to about 4mm in the direction of the center of circle, and the thickness of the positively charged conductive plate 3 is 0.2mm. Three circles of small holes are distributed on the outer periphery of the electropositive conductive plate 3, each with a diameter of 1.5 mm.

[0080] If the upper spring steel sheet is removed, the shape of the device is as follows Figure 20 shown. The insulating spacer 2 has a diameter of 6mm and a thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com