Natural gas filtering filter element with multi-stage filtering function and filter

A natural gas and grade filtration technology, applied in the fields of dispersed particle filtration, gas fuel, chemical instruments and methods, etc., can solve the problems of incomplete droplet purification, short service life, low deliquoring efficiency, etc., to improve the deliquoring efficiency and The effect of deliquoring, improving removal rate and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the combined filter element and filter for filtering natural gas with multi-stage filtering function of the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

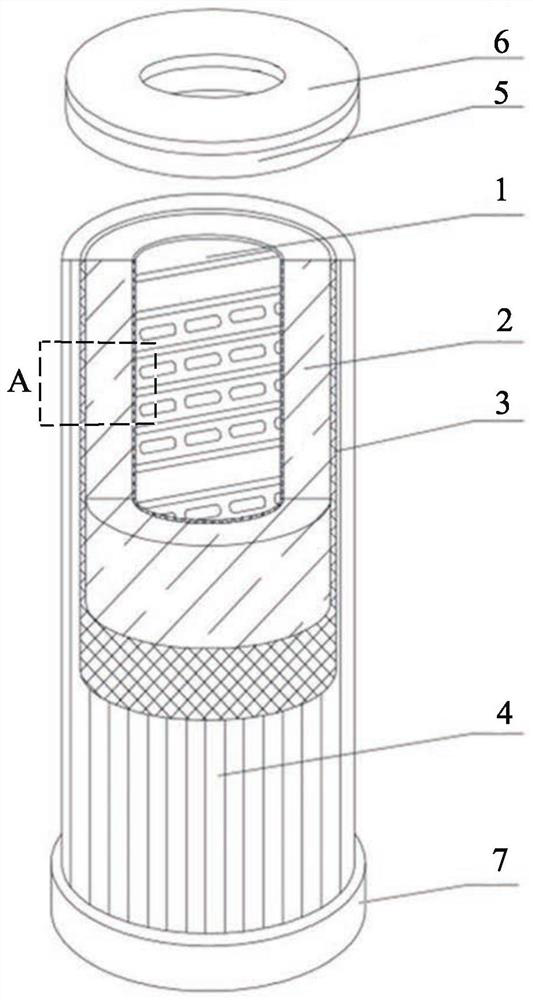

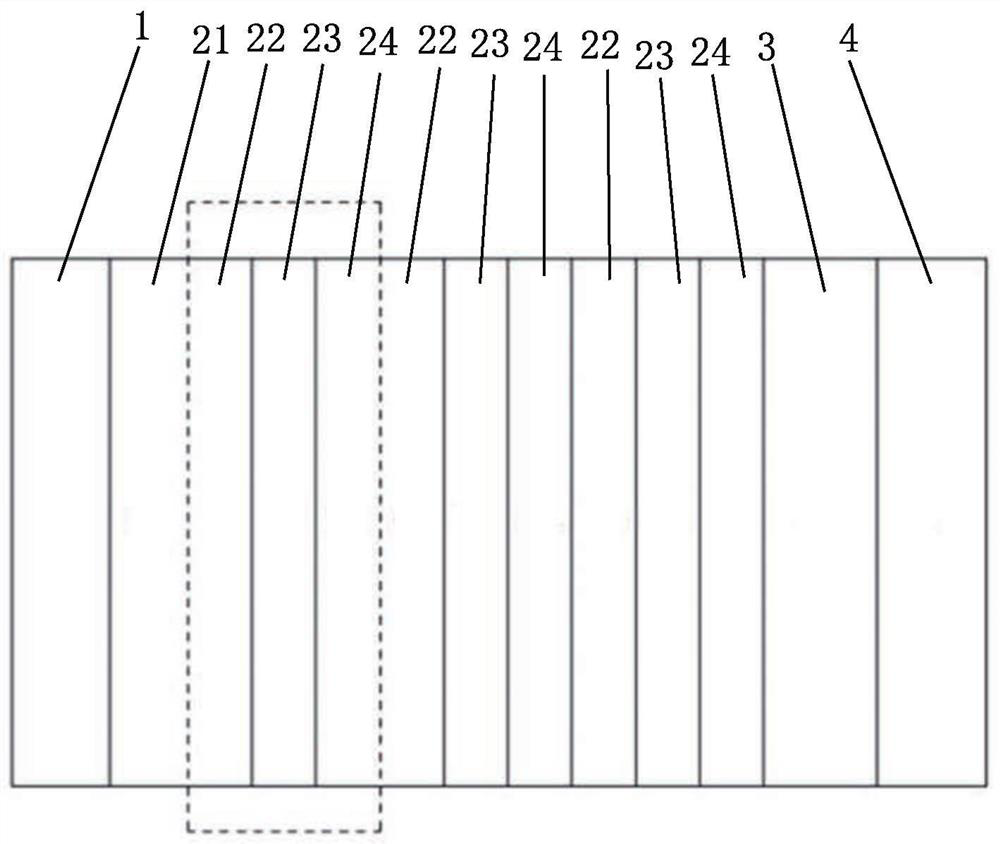

[0021] figure 1 A schematic structural view showing a combined filter element for filtering natural gas with multi-stage filtering function according to an exemplary embodiment of the present invention; figure 2 show figure 1 Schematic diagram of the structure of the medium filter body.

[0022] In the first exemplary embodiment of the present invention, the combined filter element for filtering natural gas with multi-stage filtering function includes an inner frame, a filter material body, an outer frame, and an upper end cover and a lower end cover arranged coaxially from inside to outside.

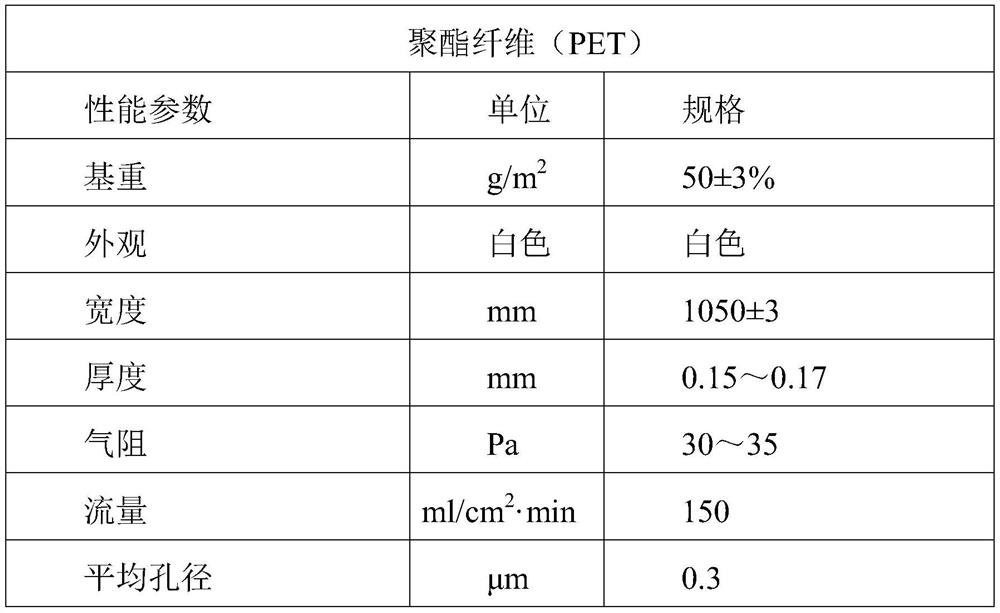

[0023] Wherein, both the inner frame and the outer frame are of cylindrical structure, a first channel for natural gas to pass is arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com