System for directly preparing liquid fuel from biomass through integrated hydrogenation pressurization catalytic pyrolysis coupling on-line upgrading

A technology of catalytic pyrolysis and liquid fuel, which is applied in the direction of waste fuel, direct heating dry distillation, and preparation of liquid hydrocarbon mixture, etc., which can solve the problems of large proportion of by-products, low economic efficiency, and potential environmental pollution

Pending Publication Date: 2021-11-16

ZHEJIANG UNIV

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] In addition to the quality of bio-oil, by-products such as gaseous products and solid biochar generated during the biomass conversion process cannot be effectively utilized, and by-products account for a large proportion of pyrolysis products, of which gaseous

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

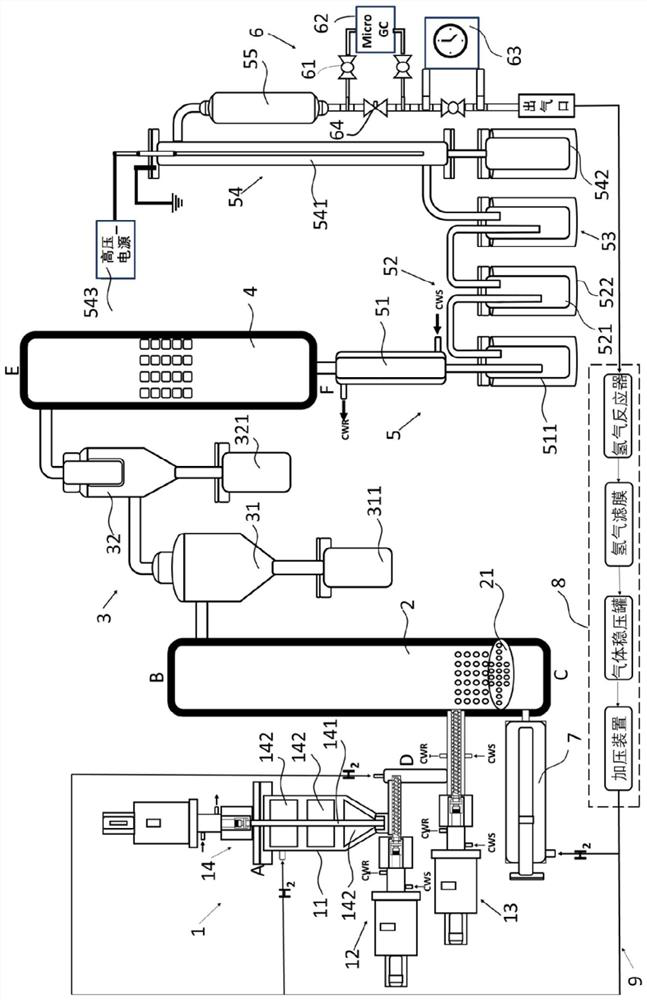

The invention relates to a system for directly preparing liquid fuel from biomass through integrated hydrogenation pressurization catalytic pyrolysis coupling online upgrading. The system comprises a biomass feeding unit, a fluidized bed reaction unit, a solid product collection unit, an online upgrading fixed bed reaction unit, a liquid product collection unit, a gas analysis unit, a steam reforming unit and a gas inlet unit which are connected in sequence. The steam reforming unit receives and reorganizes the non-condensable gas mixture after pyrolysis, and molecular hydrogen generated after reforming enters the gas inlet unit; the gas inlet unit is divided into three air paths after passing through the air path switch; a catalyst used in the online upgrading fixed bed reaction unit is a modified carbon-based catalyst; and a carbon base in the modified carbon-based catalyst comes from a solid product collected by the solid product collection unit. The liquid fuel conversion quality is high, the technological process is short, and direct preparation from biomass to liquid hydrocarbon can be completed on one device; the economic competitiveness is high, and the economical efficiency is improved through comprehensive utilization of all components of the biomass.

Description

technical field [0001] The invention relates to the technical field of renewable energy, in particular to a biomass integrated hydrogenation, pressurization, catalytic pyrolysis coupled on-line upgrading and direct production of liquid fuel system. Background technique [0002] Biomass is the only renewable energy source that can be converted directly into carbon-containing liquid fuels. Statistics show that the annual output of agricultural and forestry waste biomass in my country is as high as 460 million tons of standard coal per year. However, at present, they are often discarded or burned in open air, which has caused a series of serious secondary pollution problems. Replacing biomass with petroleum to produce liquid fuel for vehicles or aviation will not only help to establish a stable and reliable fuel supply system, but also significantly reduce greenhouse gas emissions. [0003] Among the numerous biomass utilization technologies, fast pyrolysis has been proposed a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J8/02B01J8/24C10B49/10C10B57/06C10G1/00C10G2/00B01D50/00C01B3/34C01B3/56C01B3/50

CPCB01J8/02B01J8/24C10B49/10C10B57/06C10G1/00C10G2/33C10G2/341C10G2/332C01B3/34C01B3/56C01B3/501C01B2203/0233C01B2203/047C01B2203/0475C01B2203/065Y02E50/30

Inventor 骆仲泱周庆国王凯歌蔡文飞苗斐婷周劲松余春江王树荣

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com