Medium manganese steel with heterogeneous lamellar structure and preparation method of medium manganese steel

A lamellar structure and heterogeneous technology, applied in the field of medium manganese steel materials, can solve problems such as low heating rate, product bending deformation, and lower industrial production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] According to the technical scheme of the present invention, the preparation method of manganese steel in some specific heterogeneous lamellar structures comprises the following steps:

[0049] (1) after forging an ingot comprising iron, carbon and manganese, heat it at 1100-1300° C. for 24-36 hours to perform homogenization treatment, and hot-roll the forging obtained after the homogenization treatment to obtain a hot-rolled steel plate;

[0050] (2) Heat the obtained hot-rolled steel plate to the austenite single-phase region of 800-900°C for austenitization treatment, keep it warm for 10-60 minutes, and then cool it to the two-phase region of ferrite and cementite for heat preservation , to obtain pearlite structure, and continue to cool to room temperature;

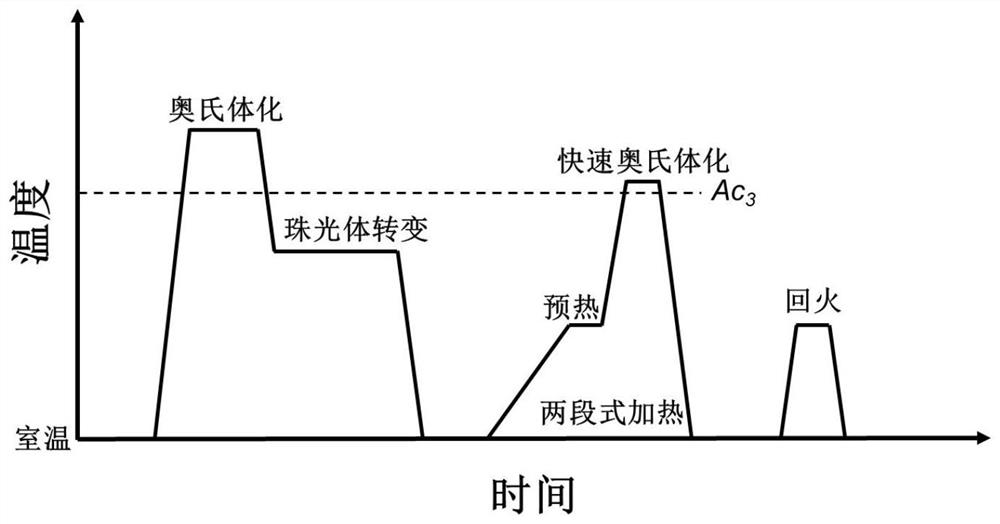

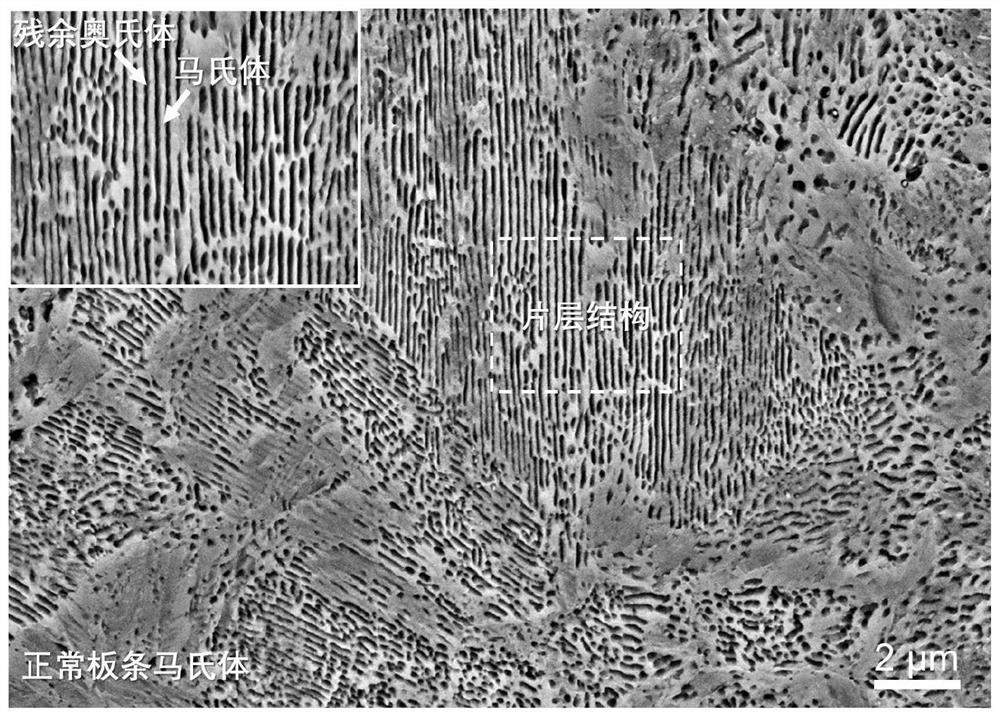

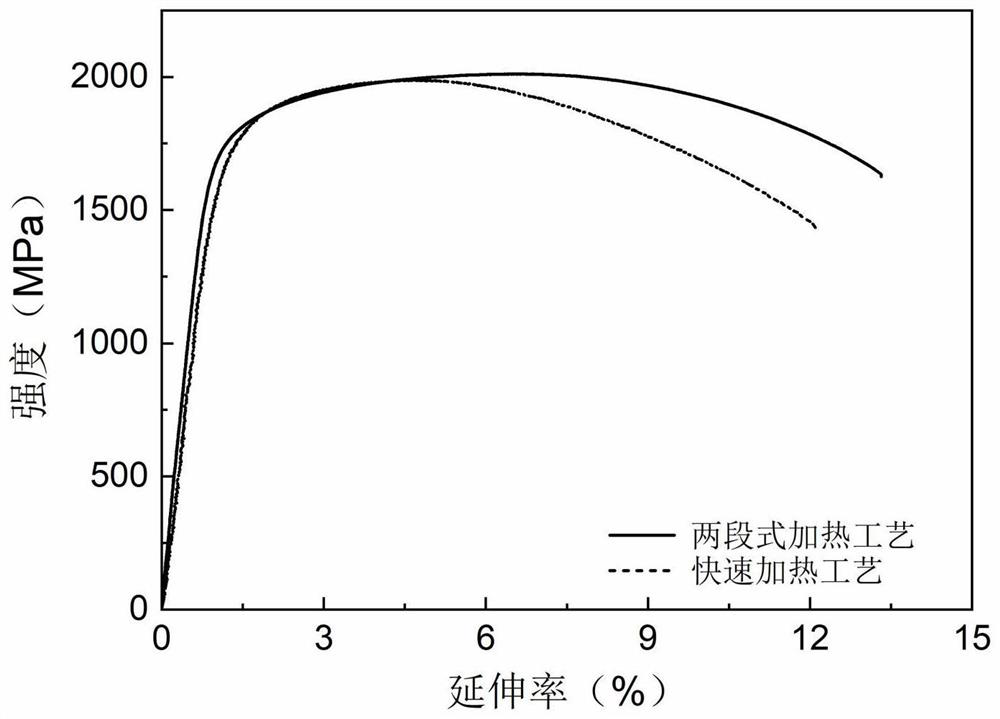

[0051] (3) Rapidly austenitize the hot-rolled steel plate after pearlite transformation through a two-stage heat treatment. The two-stage heat treatment includes: first slowly heating the hot-rolled steel plate af...

Embodiment 1

[0060] The specific composition is Fe-0.39C-3.69Mn (wt.%) steel through vacuum melting and forging to form 250*250*40mm 3 Forging; take 100×40×26mm from the center of the forging 3 The square forgings are heated to 1250°C in an argon atmosphere, and held for 24 hours for homogenization; the homogenized forgings undergo 5 to 8 rolling passes to obtain hot-rolled plates with a thickness of 6mm, and the final rolling temperature is greater than 850°C. After rolling, air-cool to room temperature to form a martensitic matrix structure.

[0061] The steel plate after hot rolling is carried out as follows: figure 1 The shown two-stage heat treatment, the specific treatment steps are as follows:

[0062] (1) The hot-rolled steel plate was kept in a muffle furnace at 800°C for 10 minutes for austenitization, then moved to a salt bath furnace at 570°C and kept for 6 hours for complete pearlite transformation, and then water quenched to room temperature;

[0063] (2) After the pearlit...

Embodiment 2

[0069] The specific composition is Fe-0.39C-3.69Mn (wt.%) steel through vacuum melting and forging to form 250*250*40mm 3 Forging; take 100×40×26mm from the center of the forging 3 The square forgings were heated to 1200°C in an argon atmosphere, and held for 36 hours for homogenization; the homogenized forgings were passed through 9 rolling passes to obtain hot-rolled plates with a thickness of 6mm, and the final rolling temperature was greater than 900°C. Air-cooled to room temperature to form a martensitic matrix structure.

[0070] The steel plate after hot rolling is carried out as follows: figure 1 Shown heat treatment, specific processing steps are as follows:

[0071] (1) Heat the hot-rolled steel plate in a muffle furnace at 850°C for 6 minutes for austenitization, then move it to a salt-bath furnace at 550°C and hold it for 12 hours, then water quench to room temperature to obtain pearlite with a higher degree of Mn partitioning ;

[0072] (2) After the pearlite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com