A low-cost anti-bending ceramic roller and its preparation method

A ceramic roller, low-cost technology, used in the production of ceramic materials, clay products, other household appliances, etc., can solve problems such as bending deformation, and achieve the effect of improving density, improving plasticity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

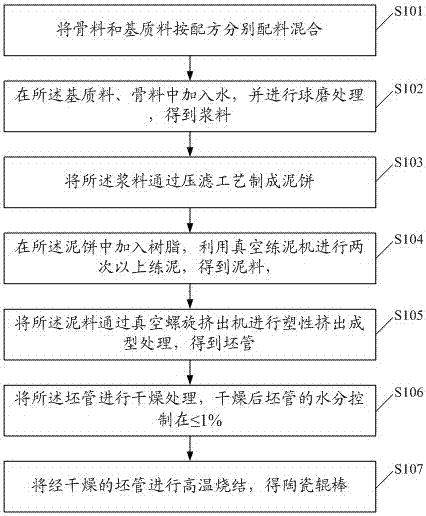

[0091] Correspondingly, as figure 1 Shown, the present invention also provides a kind of preparation method of low-cost anti-bending ceramic roller bar, comprising:

[0092] S101. Mix the aggregate and matrix material separately according to the formula.

[0093] The raw materials of the ceramic roller include aggregate, base material and resin, wherein, the main raw material formula of the aggregate in parts by weight is: 30-60 parts of ceramic roller waste;

[0094] The main raw material formulation of the base material in parts by weight is:

[0095] Cordierite 15~40 parts

[0096] Aluminum oxide 2~15 parts

[0097] Yttrium oxide 0.1~8 parts

[0098] 15~35 parts of clay;

[0099] The sum of the parts by weight of above-mentioned cordierite, ceramic roller bar waste, aluminum oxide, yttrium oxide, and clay is 100 parts, based on this, plus:

[0100] Water-soluble resin, its weight portion is 0.1~2 parts.

[0101] Preferably, the weight ratio of the aggregate to the ba...

Embodiment 1

[0139] (1) Formula:

[0140] 30 parts ceramic roller waste

[0141] Cordierite 30 parts

[0142] Aluminum oxide 10 parts

[0143] Yttrium oxide 5 parts

[0144] 25 parts clay;

[0145] 1 part of water-soluble resin.

[0146] Among them, the ceramic roller waste includes: 10 parts of ceramic roller waste with a particle size of 55 mesh, 15 parts of ceramic roller waste with a particle size of 75 mesh, and 5 parts of ceramic roller waste with a particle size of 95 mesh.

[0147] (2) Preparation method:

[0148] (1) Mix 30 parts of ceramic roller waste to obtain aggregate; mix 30 parts of cordierite, 10 parts of alumina, 5 parts of yttrium oxide, and 25 parts of clay to obtain matrix material;

[0149] (2) Mill the base material and 28 parts of water in a ball mill for 1.5 hours; put the aggregate into the ball-milled base material, and perform a second ball mill for 0.5 hours to obtain a slurry; grind the slurry Screening and iron removal treatment;

[0150] (3) The slur...

Embodiment 2

[0156] (1) Formula:

[0157] Ceramic roller waste 35 parts

[0158] cordierite 25 parts

[0159] 8 parts of aluminum oxide

[0160] 2 parts yttrium oxide

[0161] 30 parts of clay;

[0162] 0.2 parts of water-soluble resin.

[0163] Among them, the ceramic roller waste includes: 12 parts of ceramic roller waste with a particle size of 60 mesh, 18 parts of ceramic roller waste with a particle size of 80 mesh, and 5 parts of ceramic roller waste with a particle size of 100 mesh.

[0164] (2) Preparation method:

[0165] (1) Mix 35 parts of ceramic roller waste to obtain aggregate; mix 25 parts of cordierite, 8 parts of alumina, 2 parts of yttrium oxide, and 30 parts of clay to obtain matrix material;

[0166] (2) Mill the base material with 30 parts of water in a ball mill for 2 hours; put the aggregate into the ball-milled base material, and perform a second ball mill for 0.6 hours to obtain a slurry; grind the slurry Screening and iron removal treatment;

[0167] (3) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com