Method for calculating burn-off rate of one-dimensional flame furnace of mixed coal

A calculation method and flame furnace technology are applied to the calculation field of the burnout rate of a one-dimensional flame furnace to achieve the effects of wide adaptability of coal types, small deviation and high accuracy of calculation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

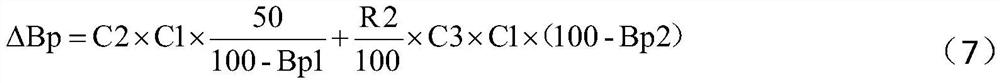

[0031] In this embodiment, a method for calculating the burnout rate of a one-dimensional flame furnace of mixed coal comprises the following steps:

[0032] Step 1: Provide the one-dimensional flame furnace burnout rate Bp1(%) of coal type 1 and the one-dimensional flame furnace burnout rate Bp2(%) of coal type 2, the blending ratio R1(%) of coal type 1 and the coal The blending ratio R2 (%) of the second type of coal, wherein R1+R2=100%, wherein the coal type one is the coal type with relatively poor burnout performance compared with the two blended coal types, that is, Bp1

[0033] Coal type one: Bp1=88%, R1=30%;

[0034] Coal type two: Bp=99.8%, R2=70%;

[0035] Step 2: Calculate the weighted average one-dimensional flame furnace burnout rate Bpc(%) of the blended coal, see formula (1) for the specific calculation method;

[0036]

[0037] The calculation result of present embodiment Bpc is as follows:

[0038]

[0039] Step 3: Calculate the nonlinear influen...

Embodiment 2

[0064] In this embodiment, a method for calculating the burnout rate of a one-dimensional flame furnace of mixed coal comprises the following steps:

[0065]Step 1: Provide the one-dimensional flame furnace burnout rate Bp1(%) of coal type 1 and the one-dimensional flame furnace burnout rate Bp2(%) of coal type 2, the blending ratio R1(%) of coal type 1 and the coal The blending ratio R2 (%) of the second type of coal, wherein R1+R2=100%, wherein the coal type one is the coal type with relatively poor burnout performance compared with the two blended coal types, that is, Bp1

[0066] Coal type one: Bp1=88%, R1=70%;

[0067] Coal type two: Bp=99.8%, R2=30%;

[0068] Step 2: Calculate the weighted average one-dimensional flame furnace burnout rate Bpc(%) of the blended coal, see formula (1) for the specific calculation method;

[0069]

[0070] The calculation result of present embodiment Bpc is as follows:

[0071]

[0072] Step 3: Calculate the nonlinear influenc...

Embodiment 3

[0097] In this embodiment, a method for calculating the burnout rate of a one-dimensional flame furnace of mixed coal comprises the following steps:

[0098] Step 1: Provide the one-dimensional flame furnace burnout rate Bp1(%) of coal type 1 and the one-dimensional flame furnace burnout rate Bp2(%) of coal type 2, the blending ratio R1(%) of coal type 1 and the coal The blending ratio R2 (%) of the second type of coal, wherein R1+R2=100%, wherein the coal type one is the coal type with relatively poor burnout performance compared with the two blended coal types, that is, Bp1

[0099] Coal type one: Bp1=98%, R1=70%;

[0100] Coal type two: Bp=99.8%, R2=30%;

[0101] Step 2: Calculate the weighted average one-dimensional flame furnace burnout rate Bpc(%) of the blended coal, see formula (1) for the specific calculation method;

[0102]

[0103] The calculation result of present embodiment Bpc is as follows:

[0104]

[0105] Step 3: Calculate the nonlinear influen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com