Treatment method for improving mainstream and sidestream smoke of Maryland tobacco

A processing method and technology for Maryland cigarettes, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of scorch, rancidity, poor sensory quality, and high irritating smoke, so as to improve the quality, improve the quality, and facilitate the The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

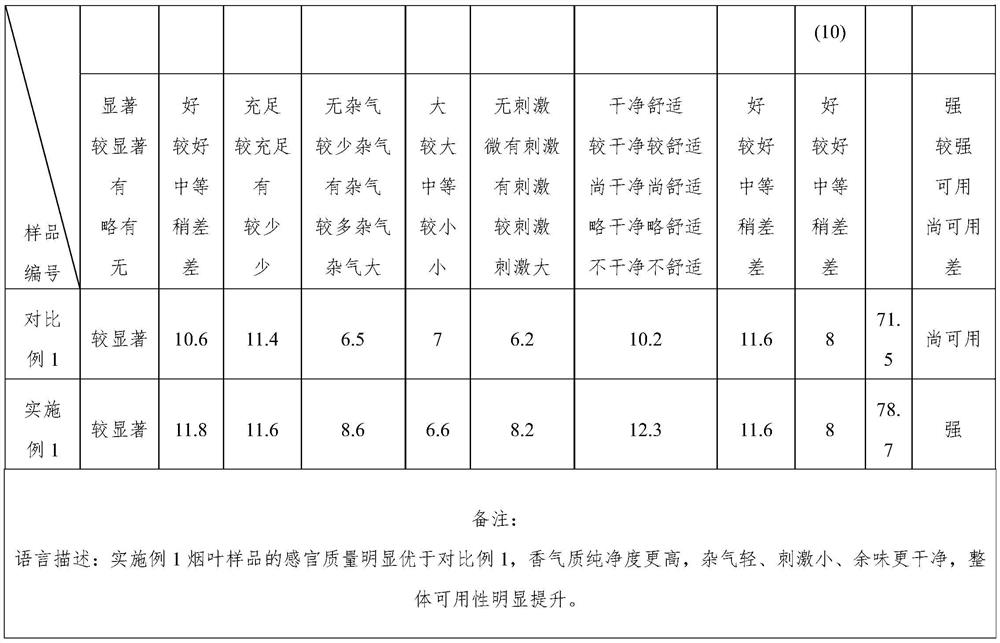

Embodiment 1

[0038] The present embodiment provides a kind of processing method of Maryland cigarette, comprises the steps:

[0039] S1. Spreading material: 8000kg of Maryland tobacco leaves are manually transported into the vacuum conditioning machine and placed evenly in layers;

[0040] S2. Vacuum dampening: vacuumize the vacuum dampening machine where the Maryland tobacco leaves are located to -0.1 MPa, inject 180°C water vapor into the vacuum dampening machine, and the ambient pressure in the vacuum dampening machine is consistent with the atmospheric pressure. The moisture content of the obtained tobacco leaves is 18wt%, and the temperature is 55°C;

[0041] S3, the first vacuuming: vacuumize the vacuum dampening machine where the tobacco leaves obtained in step S2 are located to -0.08MPa, and the vacuuming time is 3 to 5 minutes;

[0042] S4, breaking the air: injecting air into the vacuum dampening machine where the tobacco leaves obtained in step S3 are located, until the ambient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com