Clamping tool for crankshaft repairing and application method thereof

A technology for clamping tooling and crankshaft, applied in the field of clamping tooling for crankshaft repair, can solve the problem that the device cannot be clamped, and achieve the effects of easy discharge, easy shock absorption, and increased clamping degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

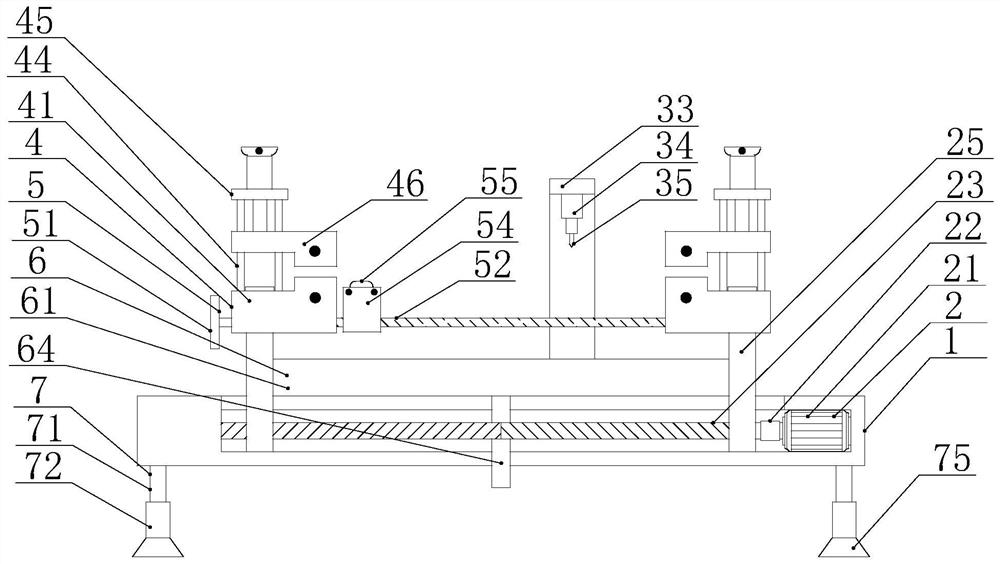

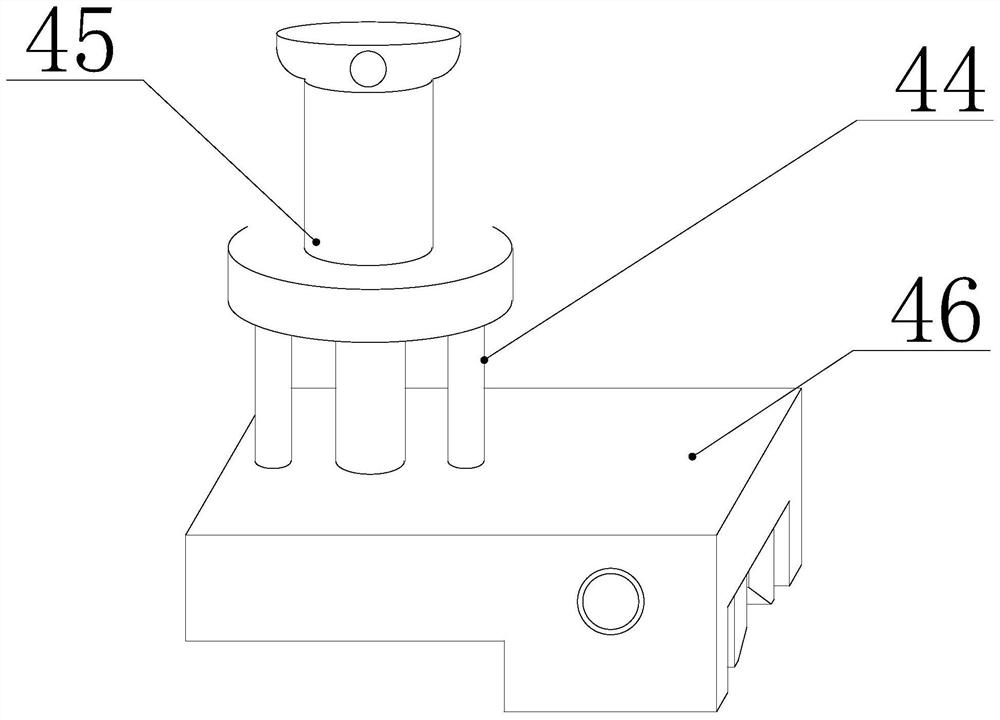

[0034] Such as Figure 1-3 As shown, the present invention is a clamping tool for crankshaft repair and its use method, including a workbench 1, a length adjustment mechanism 2 is provided inside the workbench 1, which is convenient for adjusting and adapting to crankshafts of different sizes, and the workbench 1 is close to the length adjustment mechanism 2 One end is provided with a moving mechanism 3, which is convenient for the movement of the spraying end. The top end of the length adjustment mechanism 2 is provided with a clamping mechanism 4, which is convenient for clamping and fixing the crankshaft. In addition, the top of the workbench 1 is provided with a waste discharge mechanism 6, which is convenient for the discharge of waste materials. The bottom of the workbench 1 is provided with a shock absorbing mechanism 7, which is convenient for reducing the vibration of the device. The length adjustment mechanism 2 includes a movable support plate 25, and the clamping me...

Embodiment 2

[0038] see Figure 5 , further improvements have been made on the basis of Example 1:

[0039] In order to adapt to crankshafts of different lengths, two mutually symmetrical movable support plates 25 are threaded through a first two-way threaded rod 23 and a second two-way threaded rod 24 in the device.

[0040] In this embodiment, the length adjustment mechanism 2 includes a first motor 21, the first motor 21 is fixedly connected to the inner cavity of the workbench 1, and the output end of the first motor 21 is fixedly connected with a first two-way threaded rod 23, the first two-way threaded rod 23 Both ends are symmetrically threaded to be connected with a movable support plate 25, the output end of the first motor 21 is covered with a belt 22, the first motor 21 is movably connected with a second two-way threaded rod 24 through the belt 22, and the two movable support plates 25 are threaded on the second On the two-way threaded rod 24, the belt 22 is driven by the first m...

Embodiment 3

[0044] see figure 1 , further improvements have been made on the basis of Example 1:

[0045] In order to free hands, reduce labor force, and increase work efficiency, by using the scraping mechanism 5, the scraping of the device is facilitated, and manual scraping is avoided. When unskilled, it is necessary to stop the machine for scraping, resulting in relatively low efficiency.

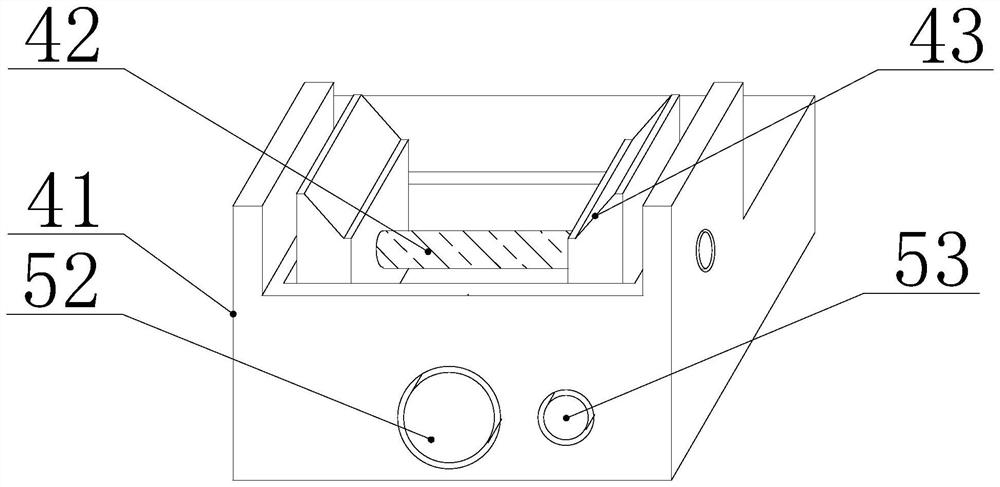

[0046] In this embodiment, the scraping mechanism 5 includes a second one-way threaded rod 52 and a limit rod 53, both of which pass through two bottom plates 41, and the second one-way threaded rod 52 and the limit rod 53 pass through a moving block 54, the handle 51 fixedly connected to one end of the second one-way threaded rod 52, and the handle 51 drives the second one-way threaded rod 52 to rotate, so that the moving block 54 can move along the limit Rod 53 moves so that scraper 55 bolted on top of moving block 54 scrapes excess debris off the crankshaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com