Method and device for constant pressure polishing of glass periphery

A glass and polishing wheel technology, used in glass production, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of low polishing quality, difficult glass, increase the complexity of processing equipment, etc., to improve polishing quality, guarantee The effect of maintaining stable machining accuracy and contact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

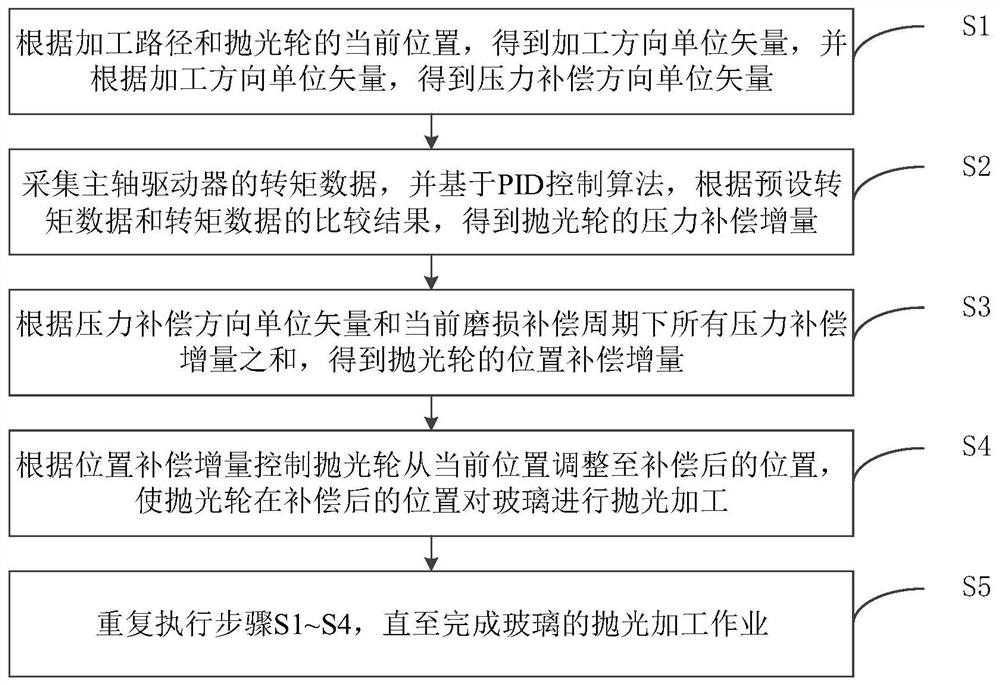

[0043] like figure 1 As shown, the first embodiment provides a constant pressure polishing method for glass periphery, including steps S1-S5:

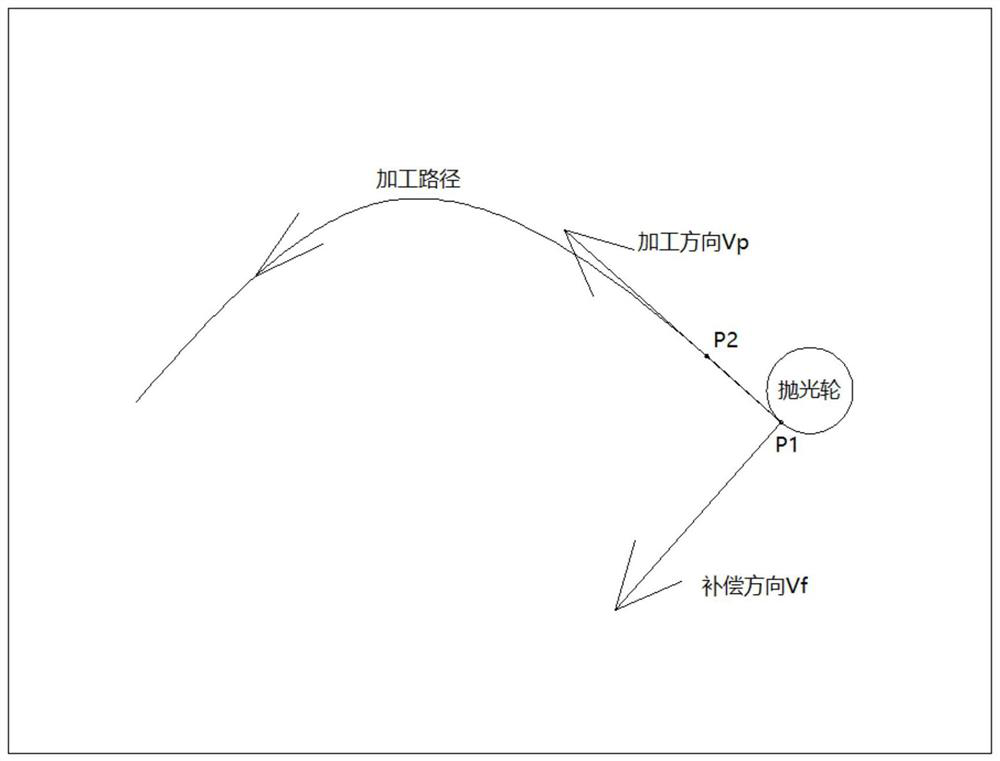

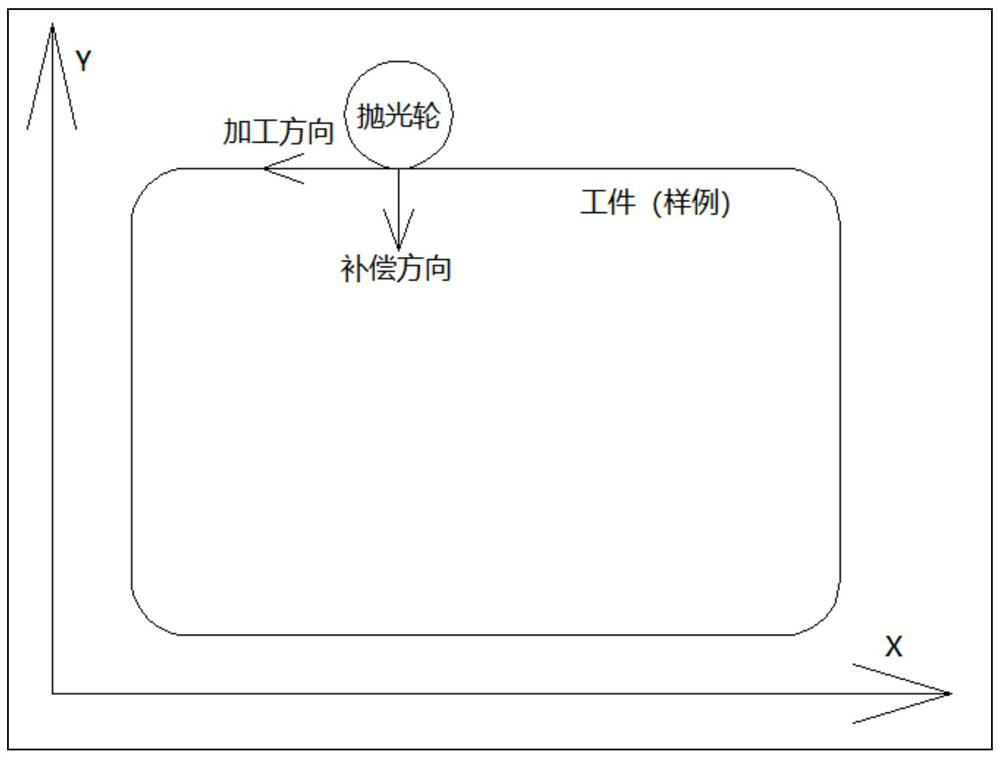

[0044] S1. Obtain the unit vector of the machining direction according to the machining path and the current position of the polishing wheel, and obtain the unit vector of the pressure compensation direction according to the unit vector of the machining direction;

[0045] S2. Collect the torque data of the spindle drive, and based on the PID control algorithm, obtain the pressure compensation increment of the polishing wheel according to the comparison result between the preset torque data and the torque data;

[0046] S3. According to the unit vector of the pressure compensation direction and the sum of all pressure compensation increments under the current wear compensation period, the position compensation increment of the polishing wheel is obtained;

[0047] S4. Control the polishing wheel to adjust from the current position to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com