High-precision environment-friendly machining equipment for hollow abrasive material and abrasive belt

A kind of processing equipment, high-precision technology, applied in the direction of metal processing equipment, grinding/polishing equipment, abrasives, etc., to achieve the effect of increasing linkage and increasing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

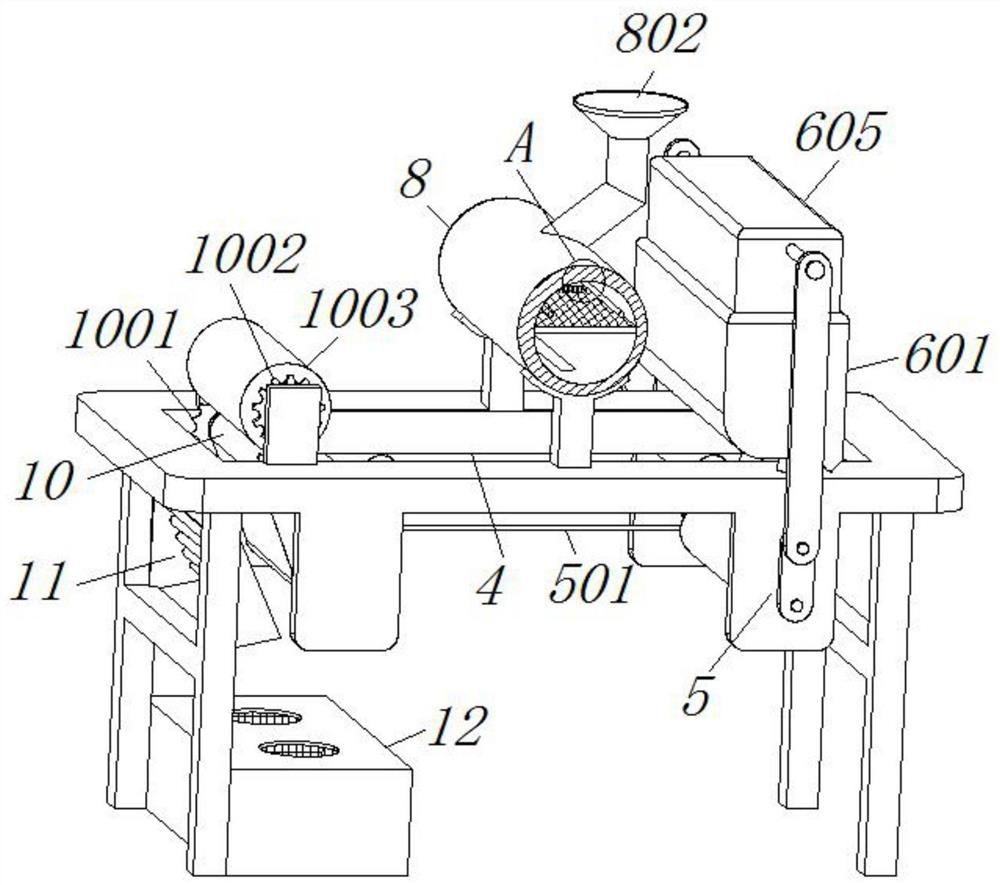

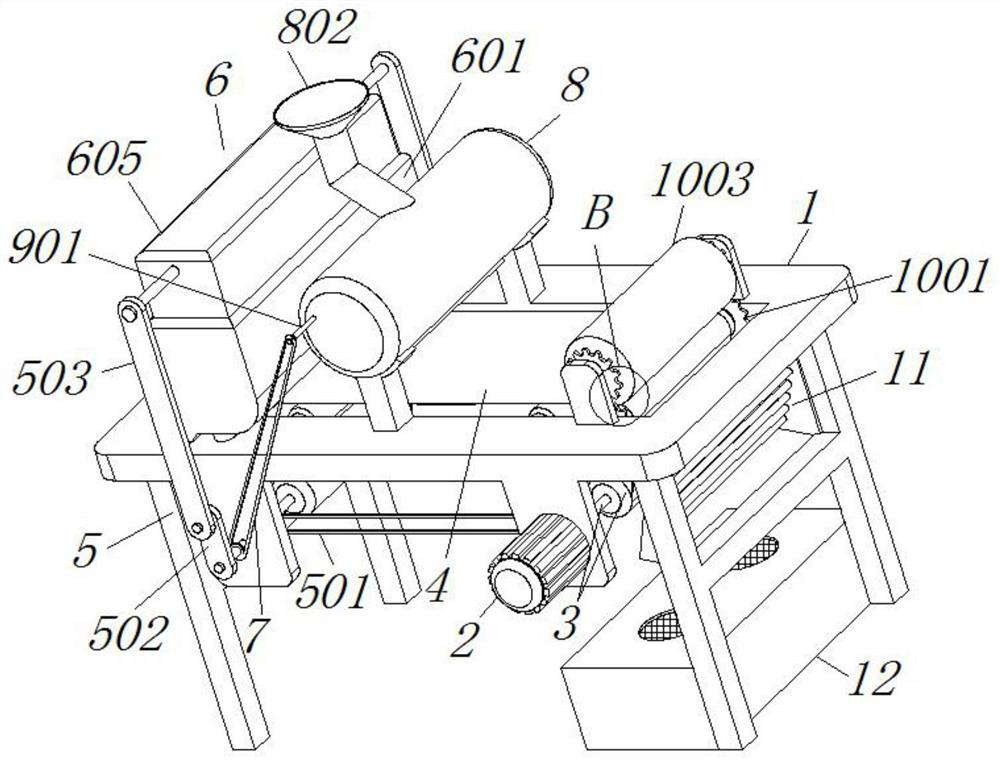

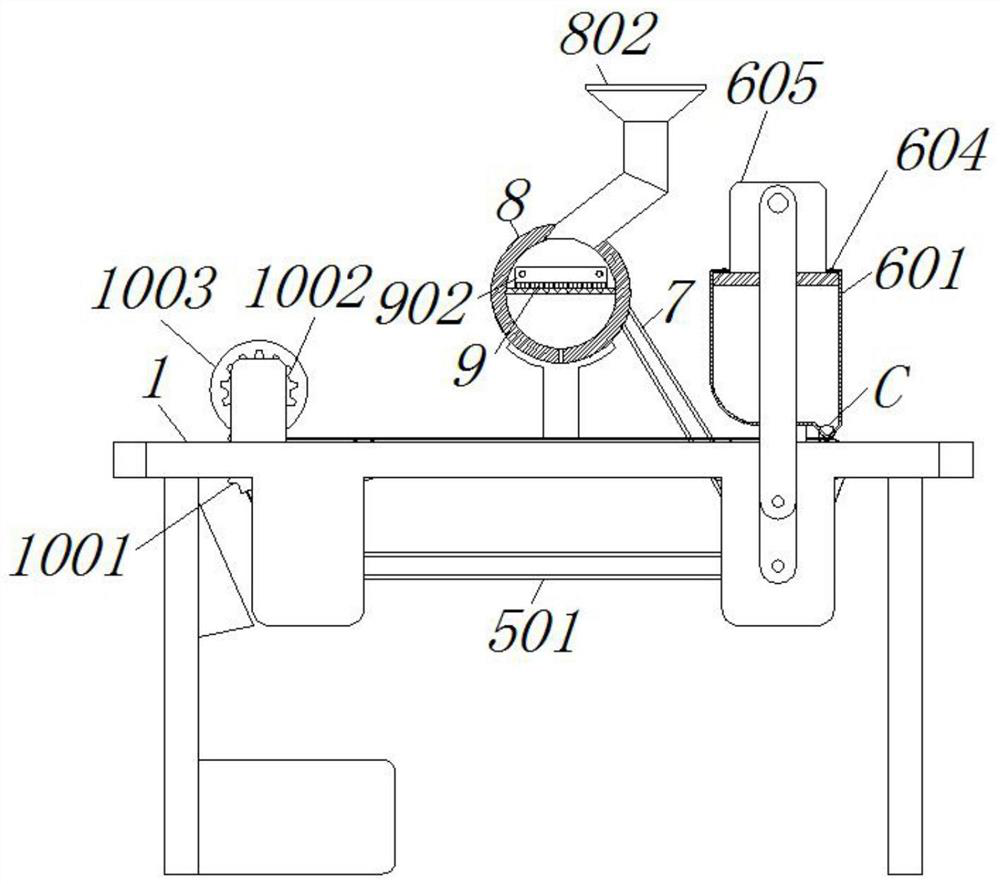

[0034] see Figure 2-3 and Figure 7 , the extrusion mechanism 5 includes a first sprocket mechanism 501 and a rotating plate 502 installed on the outside of the two main shaft revolving wheels 3, and the rotating plate 502 is connected with a connecting plate 503 through a shaft bearing, and the length of the rotating plate 502 is the connecting plate 503 A quarter of the length dimension, the uniform gluing mechanism 6 includes a material storage frame 601 fixed on the left side above the workbench 1, and the inside bottom of the workbench 1 is fixed with a gasket 602 through a rod, and the bottom of the gasket 602 is provided with a coating Soft rubber 603, one-way air valves 604 are installed on the left and right sides above the material storage frame 601, and the inner side of the material storage frame 601 is also engaged with an extrusion piston 605, and the soft rubber 603 is smeared in an opening shape, and the upper side of the extrusion piston 605 The front and re...

Embodiment 2

[0036] see Figure 3-5 , and the difference from Example 1 is: the inner side of the abrasive cylinder 8 is welded with a mesh plate 801, and the top of the abrasive cylinder 8 is provided with a feed pipe 802, the feed pipe 802 is inclined, and the uniform spreading mechanism 9 includes a bearing connected to the abrasive material. The reciprocating screw rod 901 on the inner side of the cylinder 8, and the outer side of the reciprocating screw rod 901 is threadedly connected with a slider 902, and the polished rod 903 is connected to the left side of the original reciprocating screw rod 901, and the bottom of the slider 902 is welded with a dispersing rod 904. The dispersing rod 904 Both are in contact with the screen plate 801, and the dispersing roller 904 forms a front and rear sliding structure through the slider 902 and the abrasive cylinder 8. Firstly, an appropriate amount of abrasive is introduced into the inner side of the abrasive cylinder 8 through the feeding tube...

Embodiment 3

[0038] see figure 2 and Figure 6 The difference from Embodiment 1 is that the pressing mechanism 10 includes a lower gear 1001 fixed on the right side of the main shaft winding wheel 3, and an upper gear 1002 meshes above the lower gear 1001, and a rubber rod 1003 is fixed on the upper gear 1002 through the shaft , when the main shaft on the right side rotates around the wheel 3, it can also drive the lower gears 1001 on the front and rear sides to rotate, and drive the upper gear 1002 meshed above it to rotate in the opposite direction, and the upper gear 1002 rotates to cooperate with the rotating shaft to drive the rubber rod 1003 Rotate, because the outer side of the bottom of the rubber rod 1003 is in contact with the outer side of the abrasive belt body 4 after the abrasive is spread, so the abrasive material bonded to the outer side of the abrasive belt body 4 can be compacted by the rotation of the rubber rod 1003.

[0039] The working principle of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com