A coating device and coating method for mobile phone case

A technology of mobile phone case and spraying device, which is applied to the device, spraying device, coating and other directions for coating liquid on the surface, which can solve the problems of easy denting of mobile phone case and wrong spraying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

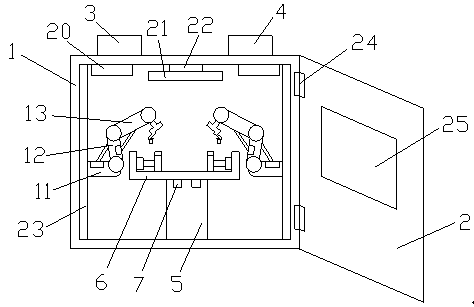

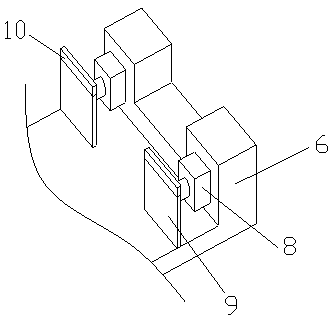

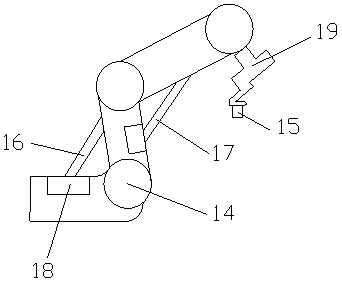

[0031] Such as Figure 1-2Shown, a kind of coating device that is used for mobile phone shell, comprises box body 1, case cover 2, is used to support the supporting device of mobile phone shell, is used for the spraying device of spraying to the surface of mobile phone shell and is used for drying treatment after spraying The heating device, the support device, the spraying device and the heating device are all located in the box body 1, the power supply 3 and the control device 4 are arranged on the box body 1, and the power supply 3 and the control device 4 are all bolted to the box body 1 connected, the supporting device includes a supporting column 5 and a supporting groove 6, the supporting column 5 is fixedly connected with the bottom of the inner wall of the box body 1, a tenon 7 is arranged on the supporting groove 6, and a tenon 7 is arranged on the supporting column 5 There is a mortise (not shown) matched with the tenon 7, the supporting groove 6 is connected with t...

Embodiment 2

[0034] Such as Figure 1-4 Shown, a kind of coating device that is used for mobile phone shell, comprises box body 1, case cover 2, is used to support the supporting device of mobile phone shell, is used for the spraying device of spraying to the surface of mobile phone shell and is used for drying treatment after spraying The heating device, the support device, the spraying device and the heating device are all located in the box body 1, the power supply 3 and the control device 4 are arranged on the box body 1, and the power supply 3 and the control device 4 are all bolted to the box body 1 connected, the supporting device includes a supporting column 5 and a supporting groove 6, the supporting column 5 is fixedly connected with the bottom of the inner wall of the box body 1, a tenon 7 is arranged on the supporting groove 6, and a tenon 7 is arranged on the supporting column 5 There is a mortise (not shown) matched with the tenon 7, the supporting groove 6 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com