A manipulator for carrying heavy objects in a radiation environment

A radiation environment and manipulator technology, applied in the field of manipulators, can solve the problems that the manipulator cannot carry heavy objects and the manipulator cannot respond to changes, and achieves the effects of stable clamping, optimized clamping capacity and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

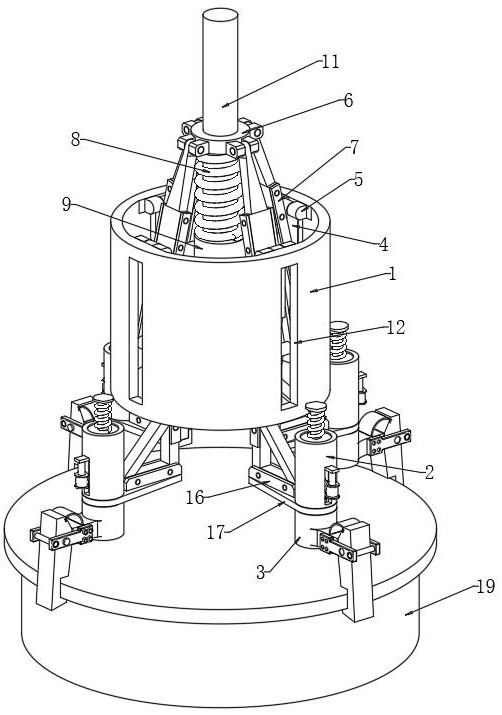

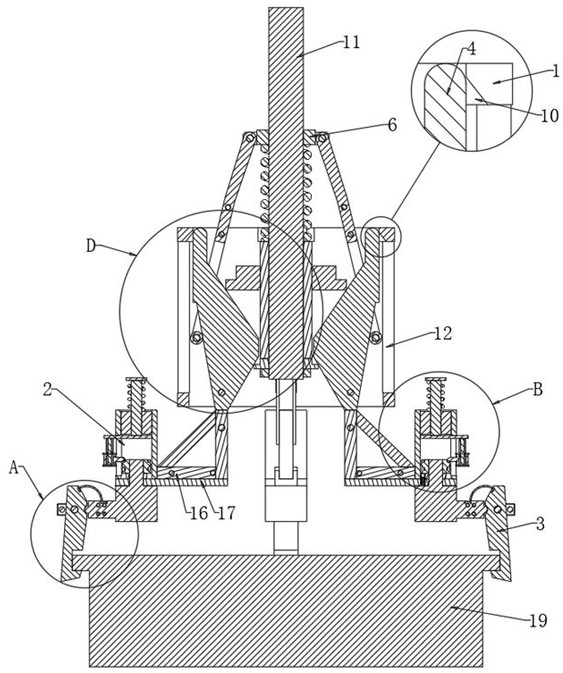

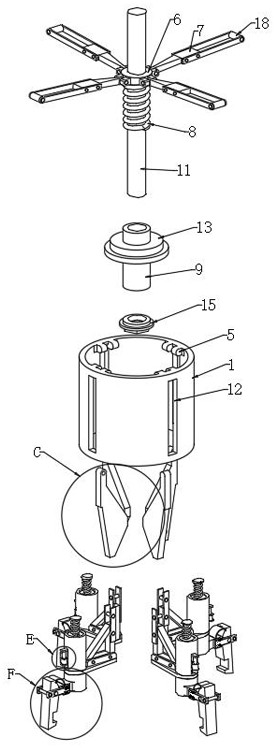

[0038] see Figure 1-11 , a manipulator for carrying heavy objects in a radiation environment, including a fixed sleeve 1, a drive shaft 11 is arranged in the middle of the inner wall of the fixed sleeve 1, and a plurality of hinge joints 5 are distributed in an array on the top of the inner wall of the fixed sleeve 1. A limit plate 4 is rotated and hinged between the hinge joints 5, and a plurality of limit plates 4 can improve the stability of clamping round and square objects. The outer side of the fixing sleeve 1 is fixedly connected with a ring 6, and the ring The outer side of 6 is hinged with a plurality of connecting plates 7, one end of the connecting plate 7 is rotatably connected with a cylindrical rolling ring 18, and the connecting plate 7 is adapted to the position of the limit plate 4, and the cylindrical rolling ring 18 is located between the limit plate 4 and the limit plate 4. Between the fixing sleeves 1, one side of the limit plate 4 is supported by the cyl...

Embodiment 2

[0048] see Figure 10-11 The difference between this embodiment and the first embodiment is that the opening of the clamping groove 305 on the clamping device 3 is far away from the middle of the fixing sleeve 1 .

[0049] Compared with the fact that the opening of the clamping groove 305 on the clamping device 3 is close to the middle of the fixing sleeve 1 , the embodiment 2 can clamp the hollow tube-like article without reducing the clamping stability.

[0050] In use: by lifting the drive shaft 11 up, the circular ring 6 is driven to move down, and then the cylindrical rolling ring 18 is moved down to achieve the limit and detachment of the limiting plate 4, and then the sliding sleeve 9 is pressed down by the circular ring 6 , so that the pressure ring 13 squeezes the limit plate 4, so that the limit plate 4 swings around the hinge joint 5, so as to increase the interval between the connecting plates 7, until the clamping device 3 and the outer wall of the barrel-shaped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com