Automatic winding packaging machine

A packaging machine, automatic technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of manpower and material resources, insecurity, time-consuming and labor-intensive, etc., to achieve the effect of simple and convenient operation, convenient packaging and use, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

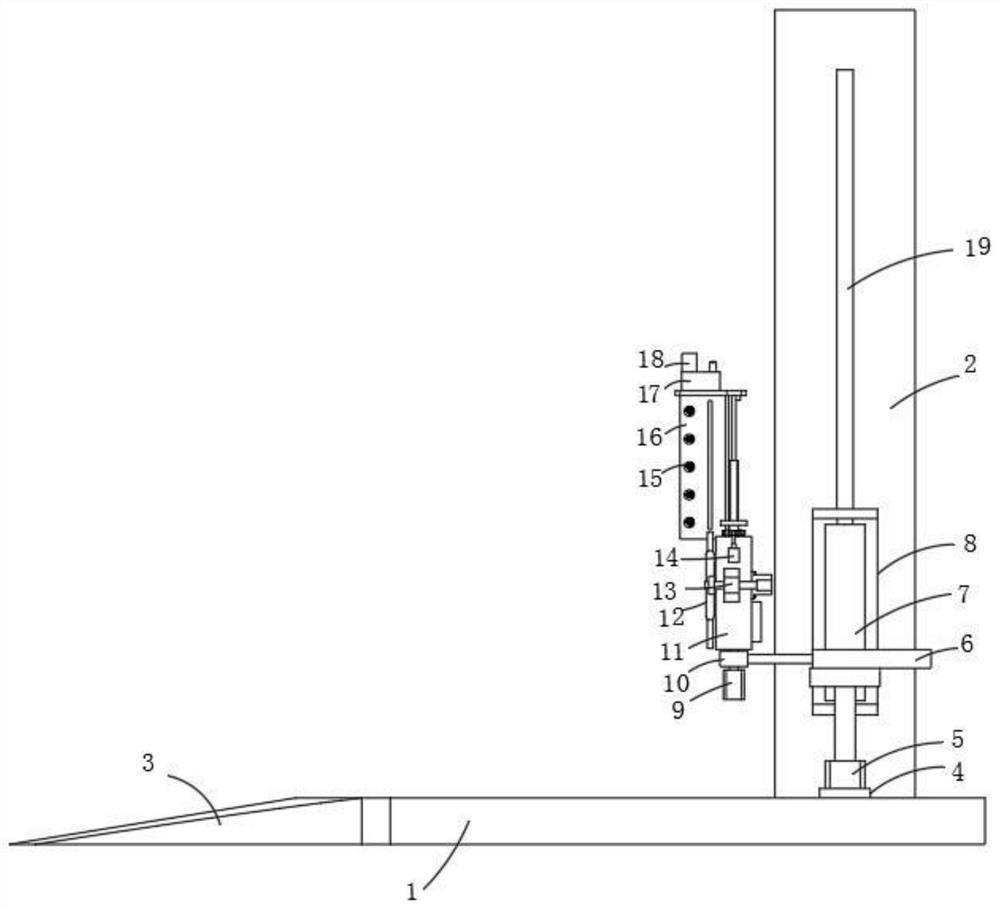

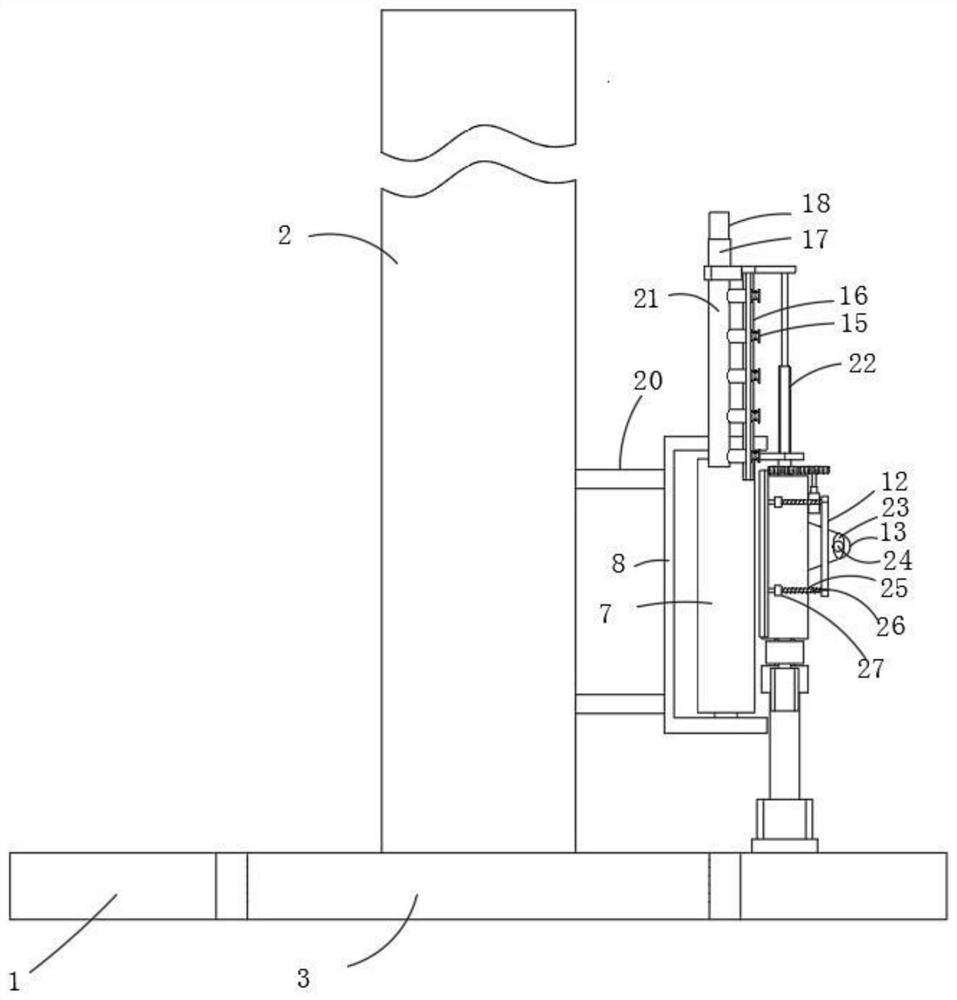

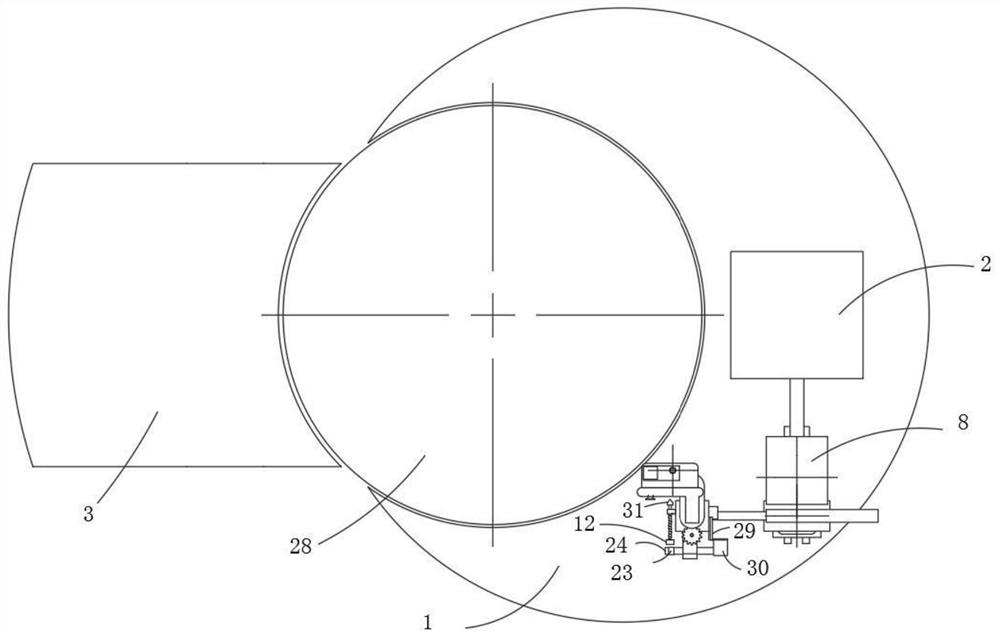

[0046] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 , an automatic wrapping packaging machine, comprising a base 1, a column 2 fixed on the top surface of the base 1 and a turntable 28 rotatably mounted on the base 1, one side of the column 2 is longitudinally provided with a sliding groove 19, the sliding groove Slide connection frame 20 is installed slidingly in 19, and the outer end of sliding connection frame 20 is fixed with film frame 8, and volume film 7 is installed on film frame 8, and volume film 7 is used for unwinding packaging film.

[0047] Please refer to figure 1 , figure 2 , image 3 , Figure 8 , The base 1 is also provided with an automatic laminating assembly, which is used for cutting off the end of the roll film 7 and laminating it on the outside of the product on the turntable 28 .

[0048] Please refer to Figure 5 , Figure 7 , the automatic fitting assembly includes a first motor base 4 installed on the base 1, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com