Cement hexavalent chromium reducing agent and preparation method thereof

A technology of hexavalent chromium and reducing agent, applied in the field of cement preparation, can solve problems such as genetic defects and skin sensitivity, and achieve the effects of reducing environmental hazards, maintaining long-term effect, and improving reducing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

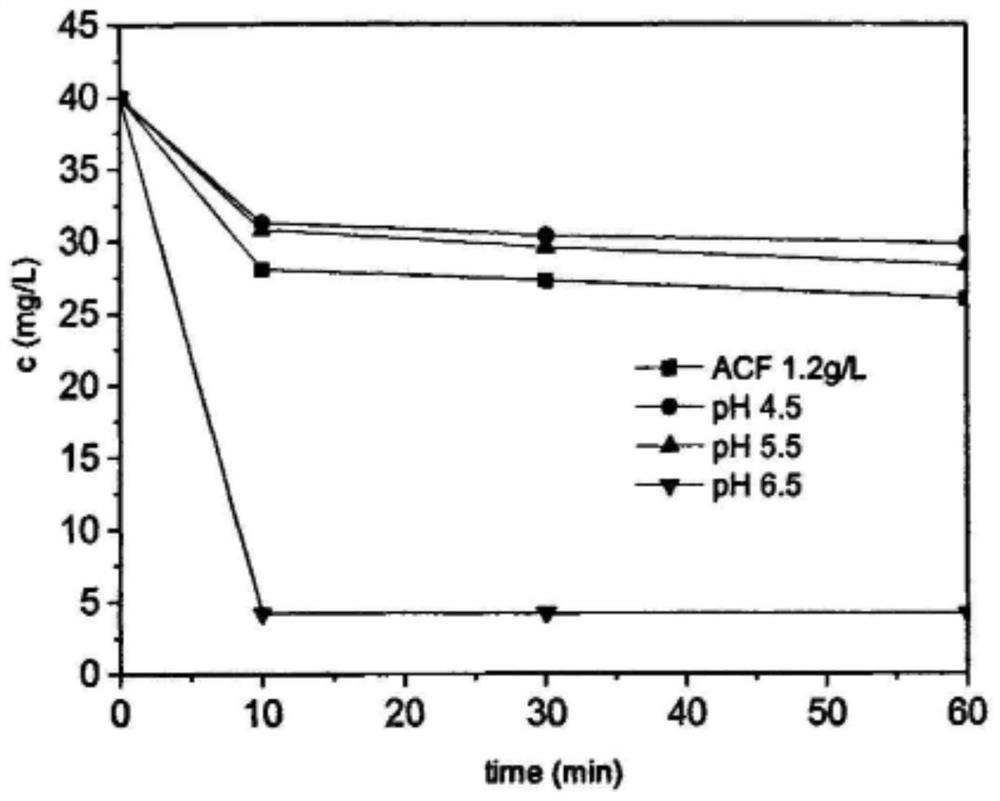

Image

Examples

Embodiment 1

[0024] The preparation steps are: dissolve one part of the prepared polycarboxylic acid hyperdispersant in water, add 5 parts of antimony trioxide, quickly shear and disperse with a shear dispersant to form a suspension, and then add 0.2 parts of an antifoaming agent to defoam The agent is a silicone defoamer, the model is XP-17;

[0025] Finally, after stirring for a period of time, add 10 parts of activated carbon fiber-supported nano-iron solution, and stir evenly to obtain the hexavalent chromium reducing agent in the form of suspension.

[0026] Activated carbon fiber-loaded nano-iron solution is prepared by the following method:

[0027] a. After pulverizing the polyacrylonitrile-based activated carbon fiber felt mucous membrane, pass it through a 300-mesh sieve, and place it in a drying oven at 100 degrees Celsius to bake for later use;

[0028] b. The nano-iron is synthesized by liquid phase reduction method, and the nano-iron is washed with deoxygenated deionized wat...

Embodiment 2

[0033] The preparation steps are: dissolve one part of the prepared polycarboxylic acid hyperdispersant in water, add 20 parts of antimony trioxide, quickly shear and disperse with a shear dispersant to form a suspension, and then add 0.5 part of a defoamer to defoam The agent is a silicone defoamer, the model is XP-17;

[0034] Finally, after stirring for a period of time, 15 parts of activated carbon fiber-supported nano-iron solution was added and stirred evenly to obtain a hexavalent chromium reducing agent in the form of a suspension.

[0035] Activated carbon fiber-loaded nano-iron solution is prepared by the following method:

[0036] a. After pulverizing the polyacrylonitrile-based activated carbon fiber felt mucous membrane, pass it through a 300-mesh sieve, and place it in a drying oven at 100 degrees Celsius to bake for later use;

[0037] b. The nano-iron is synthesized by liquid phase reduction method, and the nano-iron is washed with deoxygenated deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com