Segmental assembled prestressed steel-wood combined truss rod piece and mounting method thereof

A steel-wood combination and truss member technology is applied in truss bridges, building components, and long-strip structural components for load-bearing, etc., which can solve the problems of steel-wood composite truss web members that cannot bear the pressure and high section stiffness, etc. To achieve the effect of convenient and reliable node connection, high bearing capacity, easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

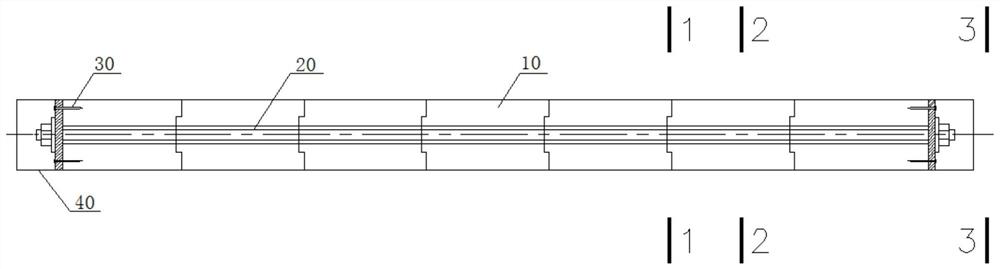

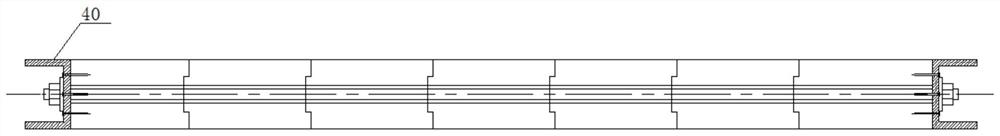

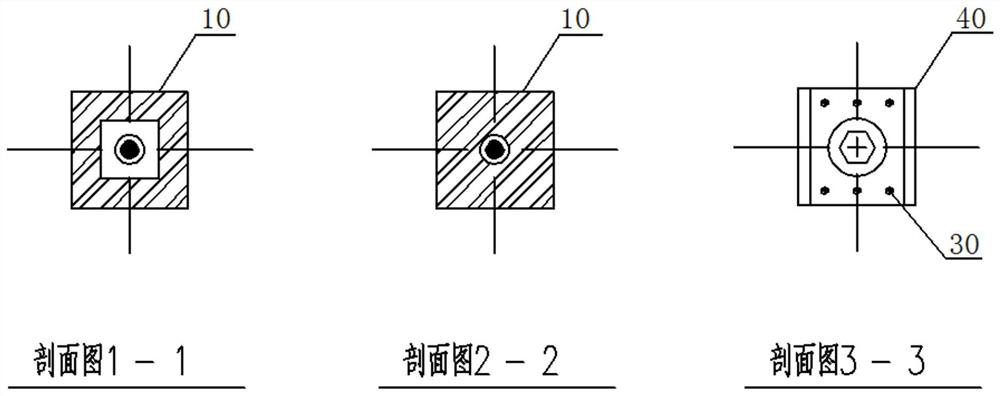

[0034] Such as Figure 1-3 As shown, a segmentally assembled prestressed steel-wood composite truss member 100 provided by an embodiment of the present invention can be used for a roof truss or a bridge of a steel-wood composite structure truss. The steel-wood composite truss member 100 includes several wooden member segments 10 , prestressed threaded steel bars 20 , shear anchor nails 30 at the ends and steel connectors 40 at the ends.

[0035] Such as Figure 4 As shown, the first and last ends of the wooden pole segment 10 are respectively provided with flanges 11 and notches 12 adapted to each other, and the middle part is provided with a central circular hole 13 for the prestressed threaded steel bar 20 to pass th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com