Diamond anvil cell pressurizing method capable of providing high static loading capacity

A technology of diamond anvil and static loading, applied in the direction of applying stable tension/pressure to test the strength of materials, teaching models, instruments, etc., can solve the problems of diamond-BC8 phase transition damage, etc., to promote development and expand stress The effect of loading range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

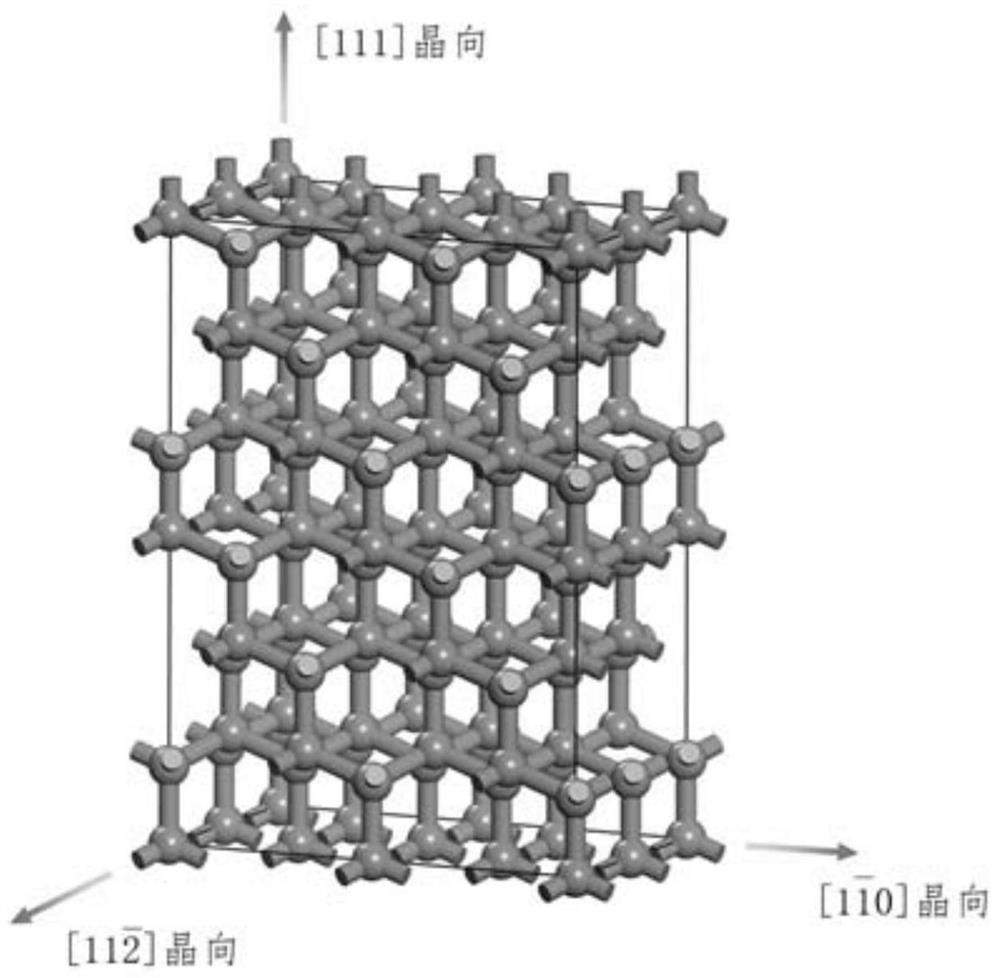

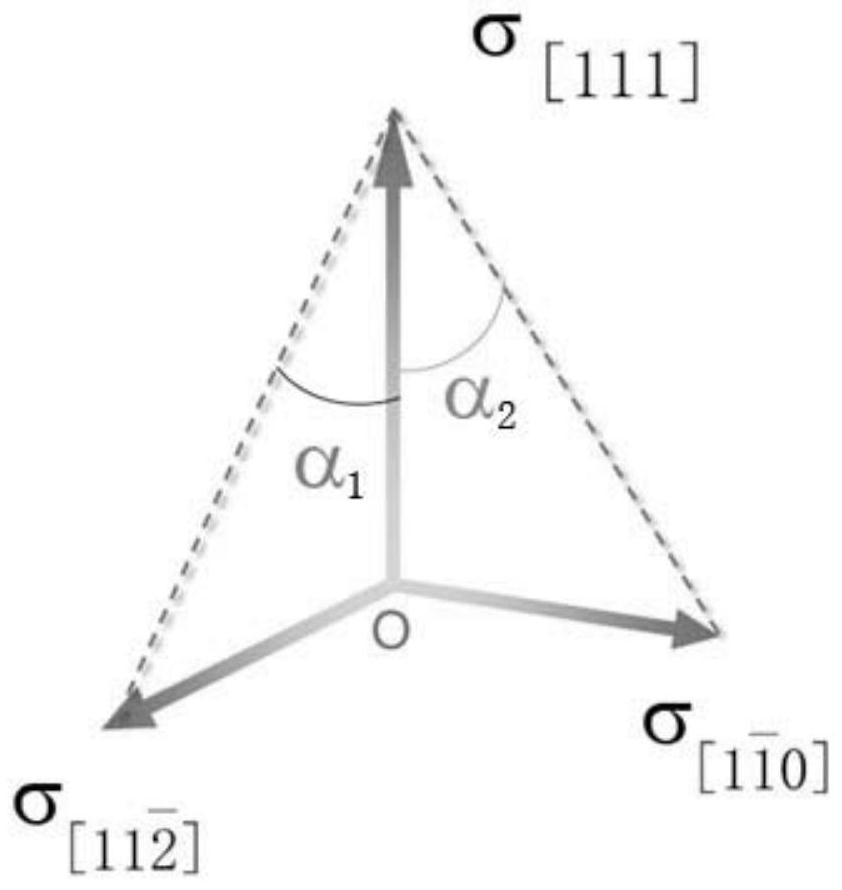

[0070] Specific implementation mode one: refer to figure 1 and figure 2 This embodiment is described in detail. A diamond-anvil pressurization method that provides high static loading capacity described in this embodiment includes the following steps:

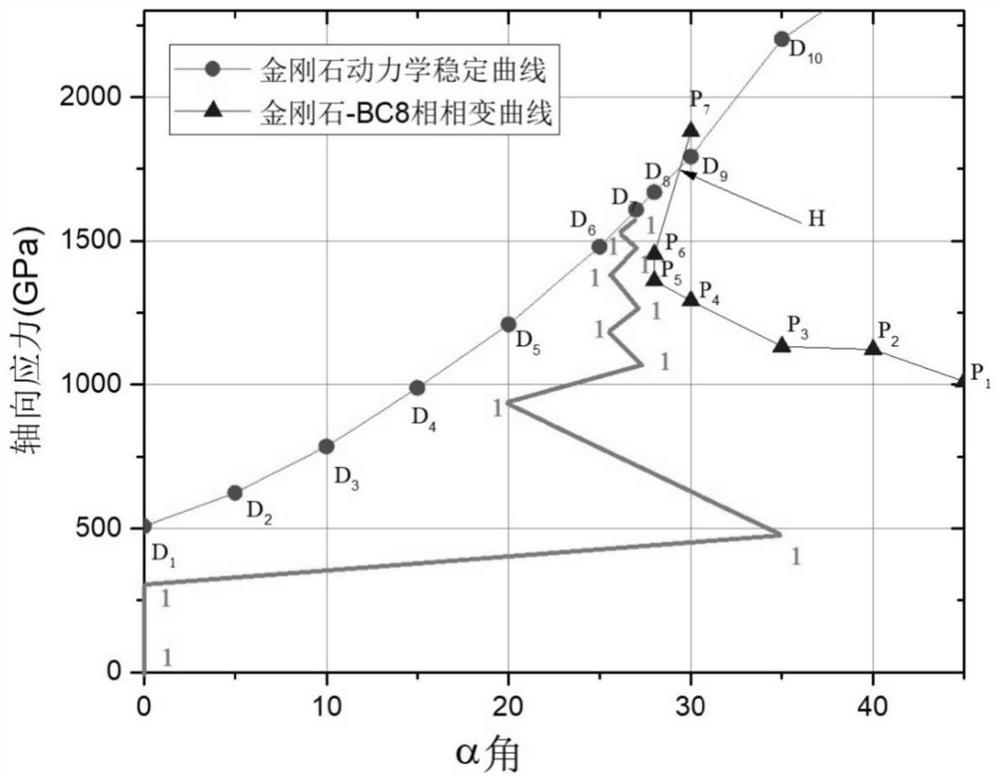

[0071] By adjusting the orientation angle α at least once 1 、α 2 and the normal stress σ of the diamond [111] orientation [111] , make 1100GPa[111] ≤1700GPa (considering the error, the final value is 1100GPa[111] ≤1800GPa), direction angle α 1 and alpha 2 Satisfy:

[0072]

[0073] Among them, α 1 = α 2 , 0°1 2 [111] is the normal stress of the diamond [111] crystal orientation, and the orientation angle α 1 is the origin O in the crystal system, diamond normal stress and the normal stress σ of the diamond [111] orientation [111] The angle between the [111] crystal direction and the hypotenuse in the formed right triangle, the direction angle α 2 is the origin O in the crystal system, diamond normal stress ...

specific Embodiment approach 2

[0075] Embodiment 2: This embodiment is a further description of Embodiment 1. The difference between this embodiment and Embodiment 1 is to adjust the direction angle α 1 and alpha 2 The step of pre-compressing the diamond is also included before;

[0076] The specific steps of pre-compressing the diamond are as follows: first, slowly load along the diamond [111] crystal direction by compression, and gradually increase the pressure during the loading process, so that the strain of the diamond [111] crystal direction is 2-5%. After holding for 1 minute, gradually remove the compressive load;

[0077] The compression method includes a uniaxial static load compression method and an isostatic compression method;

[0078] The uniaxial static load compression method, namely locking α 1 = 0°, α 2 = 0°;

[0079] The isostatic compression method, namely locking α 1 = 45°, α 2 = 45°.

[0080] The diamond is pre-compressed to avoid the damage of the anvil head and the reduction ...

specific Embodiment approach 3

[0081] Embodiment 3: This embodiment is a further description of Embodiment 2. The difference between this embodiment and Embodiment 2 is that the steps of the pressurization method are as follows:

[0082] Step 1: Through uniaxial static load compression, that is, to lock α 1 = 0°, α 2 = 0°, slowly load along the diamond [111] crystal direction; during the loading process, gradually increase the force of the diamond [111] crystal direction, so that the normal stress σ of the diamond [111] crystal direction [111] Reach 60GPa, at this time, the strain of the diamond [111] crystal direction is 4%; after holding for 1 minute, gradually remove the compressive load, so that the normal stress of the diamond [111] crystal direction is reduced to 0;

[0083] Step 2: Through the uniaxial static load compression method, that is, α 1 = 0°, α 2 = 0°, slowly load along the diamond [111] crystal direction; during the loading process, gradually increase the force of the diamond [111] crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com