High-strength all-insulation large-current direct-current bus fastening assembly

A technology for DC bus and fastening components, applied in the electrical field, can solve the problems of bulky porcelain bottle insulators, fracture at the glued part, poor shear resistance, etc., and achieves small installation space, good insulation performance, and strong flame retardant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

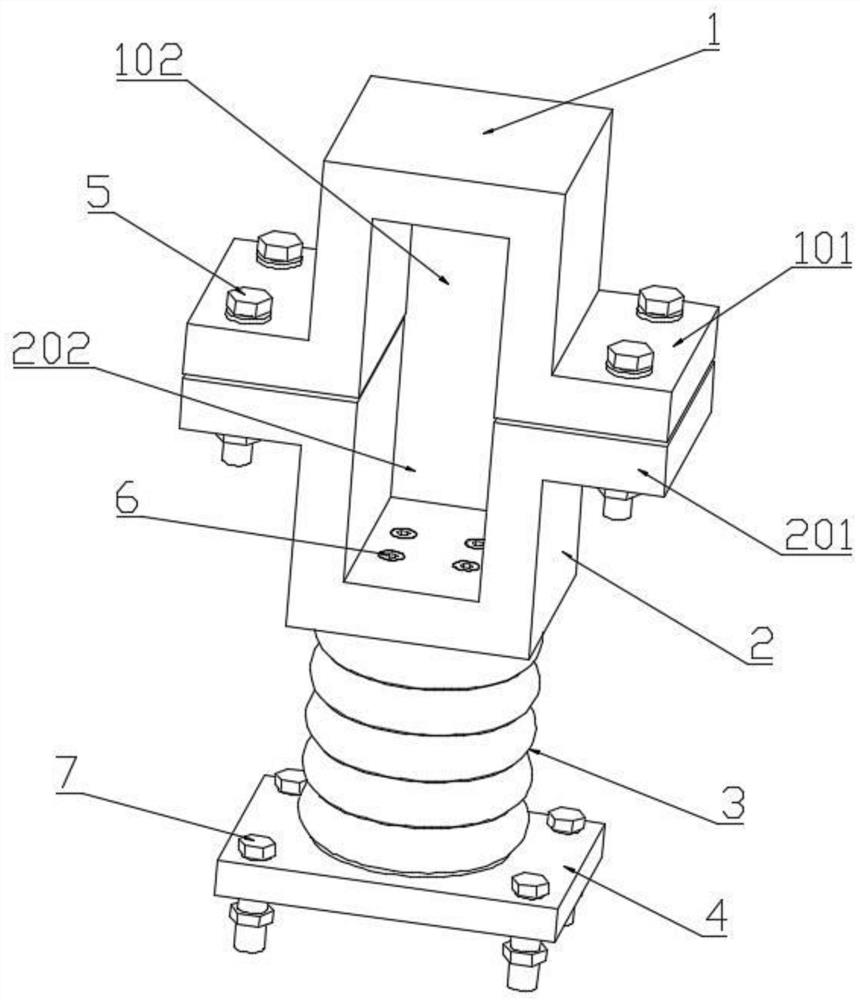

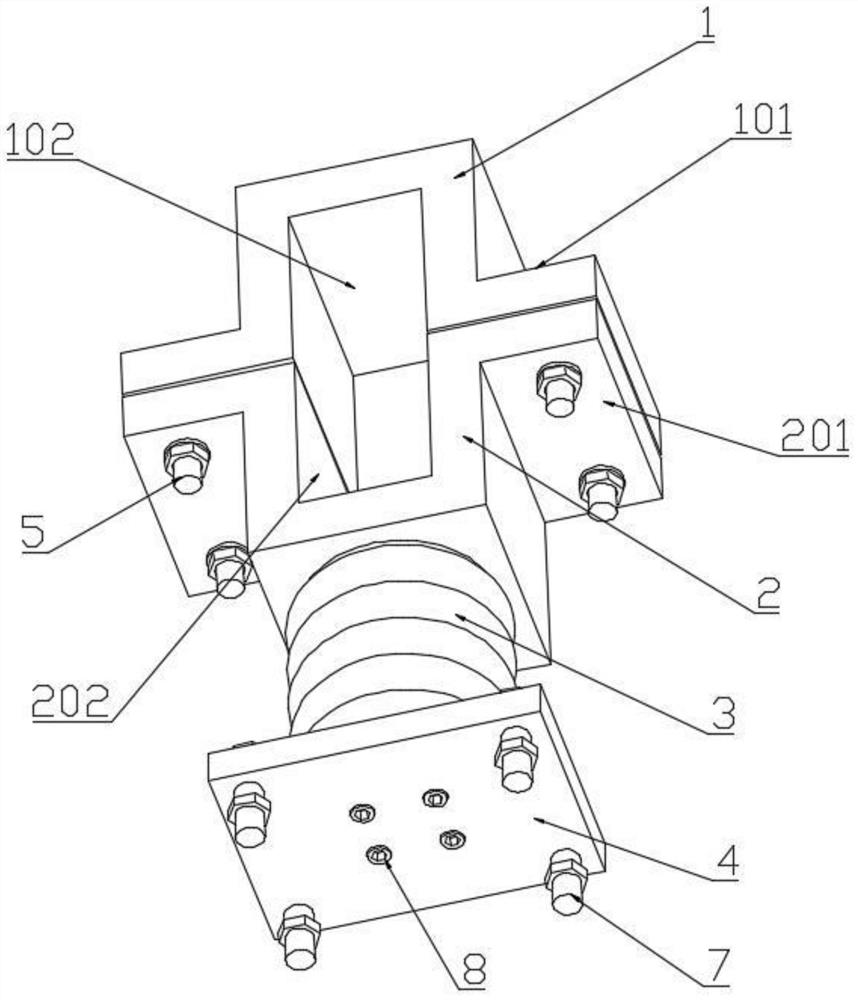

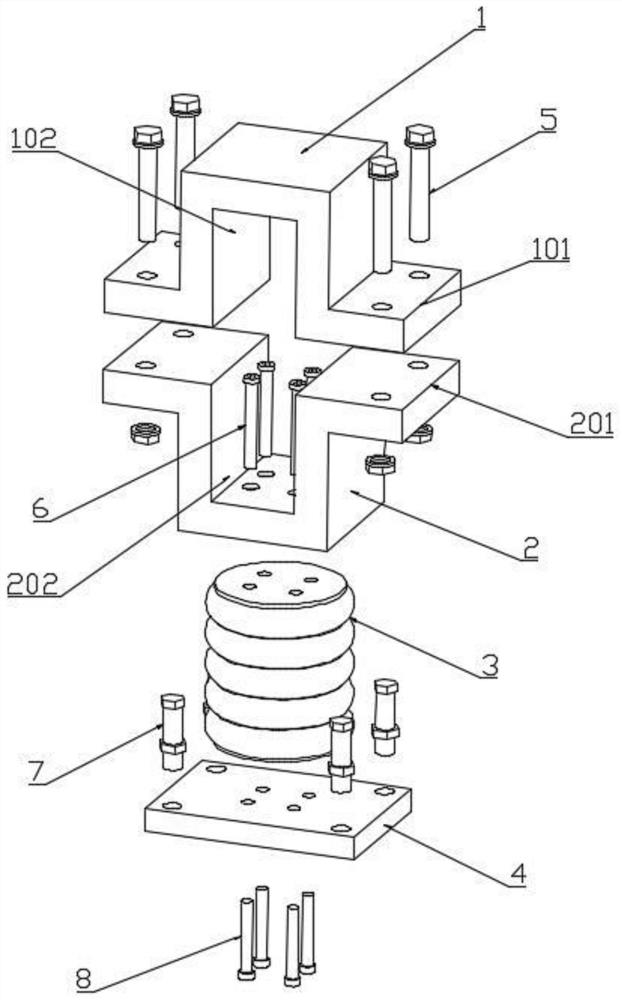

[0022] A high-strength fully insulated high-current DC busbar fastening assembly of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] combined with Figure 1-Figure 5 , a high-strength fully insulated high-current DC busbar fastening assembly, including a first clamp 1, a second clamp 2, an insulator 3 and a connecting plate 4, the first clamp 1 is formed by a first U-shaped splint 102 and is arranged on the second clamp A splint 102 two ends of the first connecting platform 101 is formed, the second fixture 2 is made up of the second U-shaped splint 202 and the second connecting platform 201 arranged at the second splint 202 two ends, the first connecting platform 101 and the The second connecting platforms 201 are fixedly connected by first bolts 5 , the bottom of the second U-shaped clamp 202 is connected to one end of the insulator 3 , and the other end of the insulator 3 is connected to the connecting p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap