Three-dimensional baking powder matt blush and preparation method thereof

A three-dimensional, matte technology, used in body powder, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of easy sweating and makeup removal of users, and achieve the effect of improving adhesion, improving skin feel, and enhancing skin feel. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

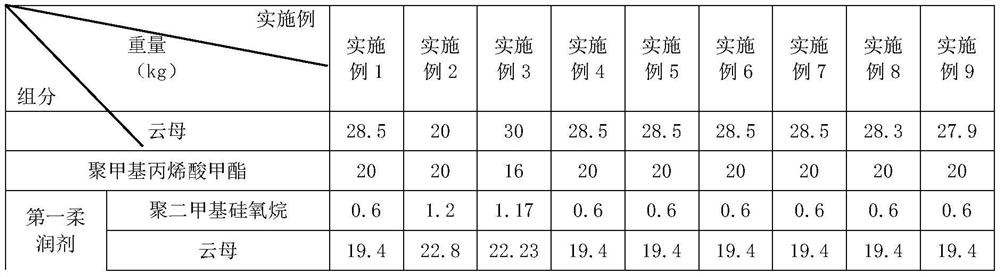

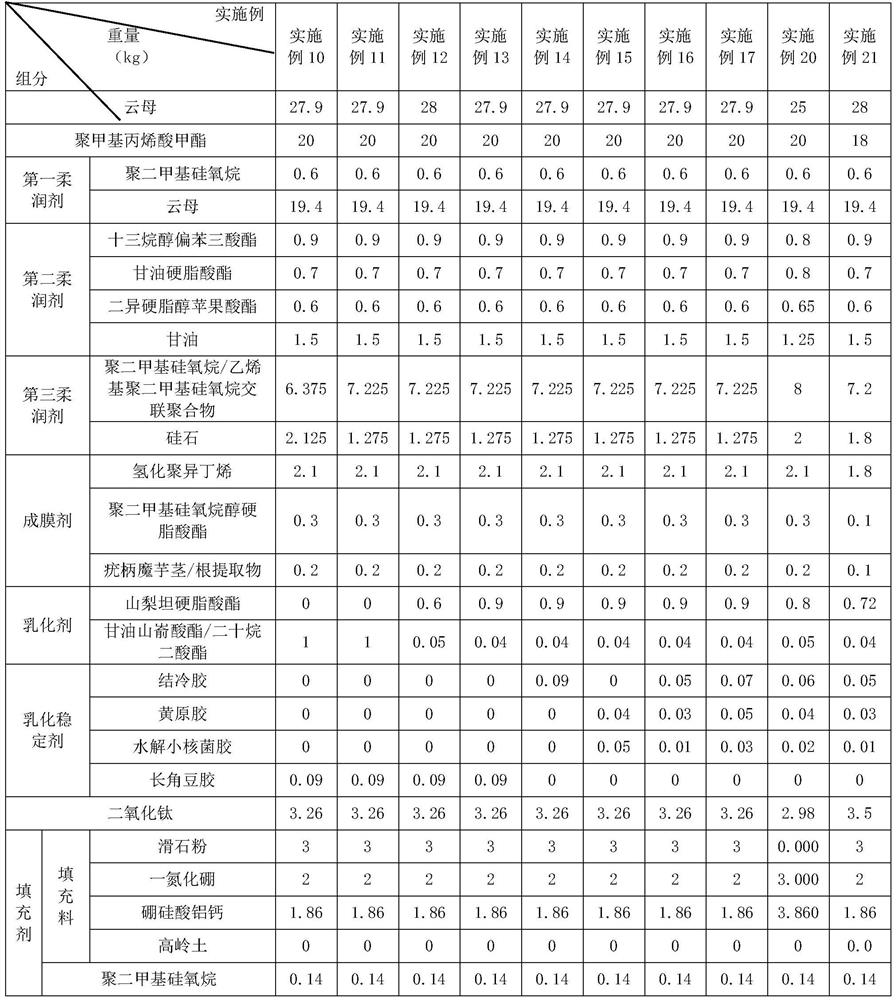

[0065] Embodiment 1: a kind of three-dimensional baked powder matte blush, included concrete components and weight are as shown in table 1, are made by following steps:

[0066] S1: Mix and stir mica, titanium dioxide, filler, colorant, and pearlescent agent at a stirring speed of 600r / min, and obtain the first mixture after stirring evenly;

[0067] S2: Add polymethyl methacrylate, the first emollient, the second emollient, the third emollient, film forming agent, emulsifier, emulsion stabilizer, polysorbate-60, preservative in the first mixture Mixing and stirring, the stirring speed is 500r / min, and the second mixture is obtained after stirring evenly;

[0068] S3: Freeze the second mixture, the freezing temperature is -28±2°C; bake after freezing, the baking temperature is 95°C, and the baking time is 1.5h; and then cool at 25±2°C to obtain Dimensional baked powder matte blush.

Embodiment 2-3

[0069] Embodiment 2-3: a kind of three-dimensional baked powder matte blush, the difference with embodiment 1 is that the specific components and weight are different, and the specific components and weight included are as shown in table 1.

Embodiment 4-5

[0070] Embodiment 4-5: a kind of three-dimensional baked powder matte blush, the difference with embodiment 1 is that the component and weight of filler are different, and the concrete component that comprises and weight are as shown in table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com