An Efficient Attapulgite Forming Equipment

A technology for attapulgite and molding equipment, which is applied in cocoa, grain processing, food science, etc., can solve the problems of low efficiency of attapulgite, low quality of concave stick, and difficulty in direct use, etc., to improve fluency, improve Filter and improve the effect of fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

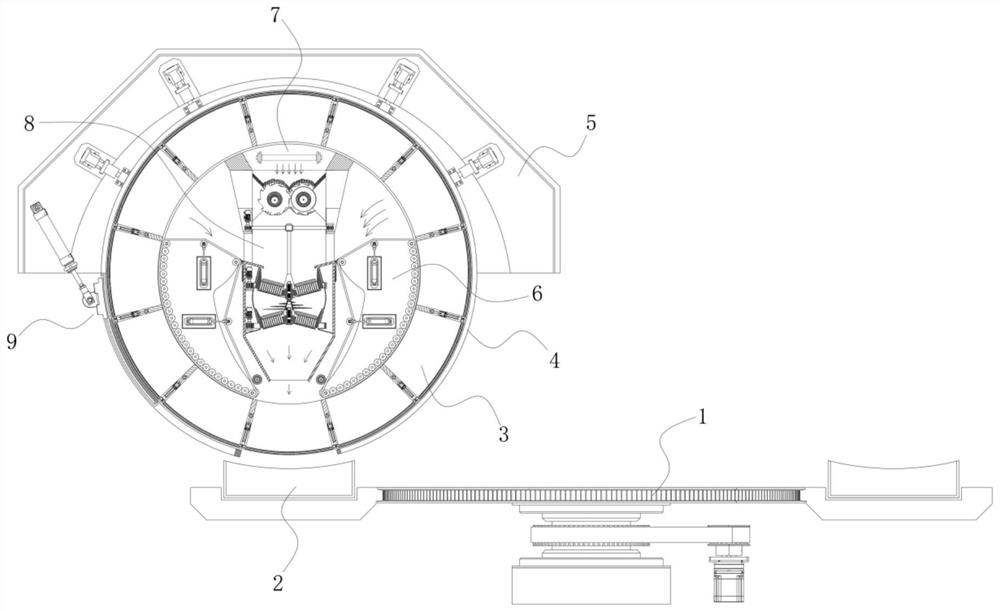

[0047] refer to Figure 1-6 , the present invention provides a technical solution: a high-efficiency attapulgite forming equipment, which includes:

[0048] The collection box 2 is installed on the rotating disk 1, and multiple groups are arranged in a circle;

[0049] The annular shell 4 is arranged above a group of the collection boxes 2, and is provided with a discharge port at its corresponding end, and is fixed on the fixed shell 5;

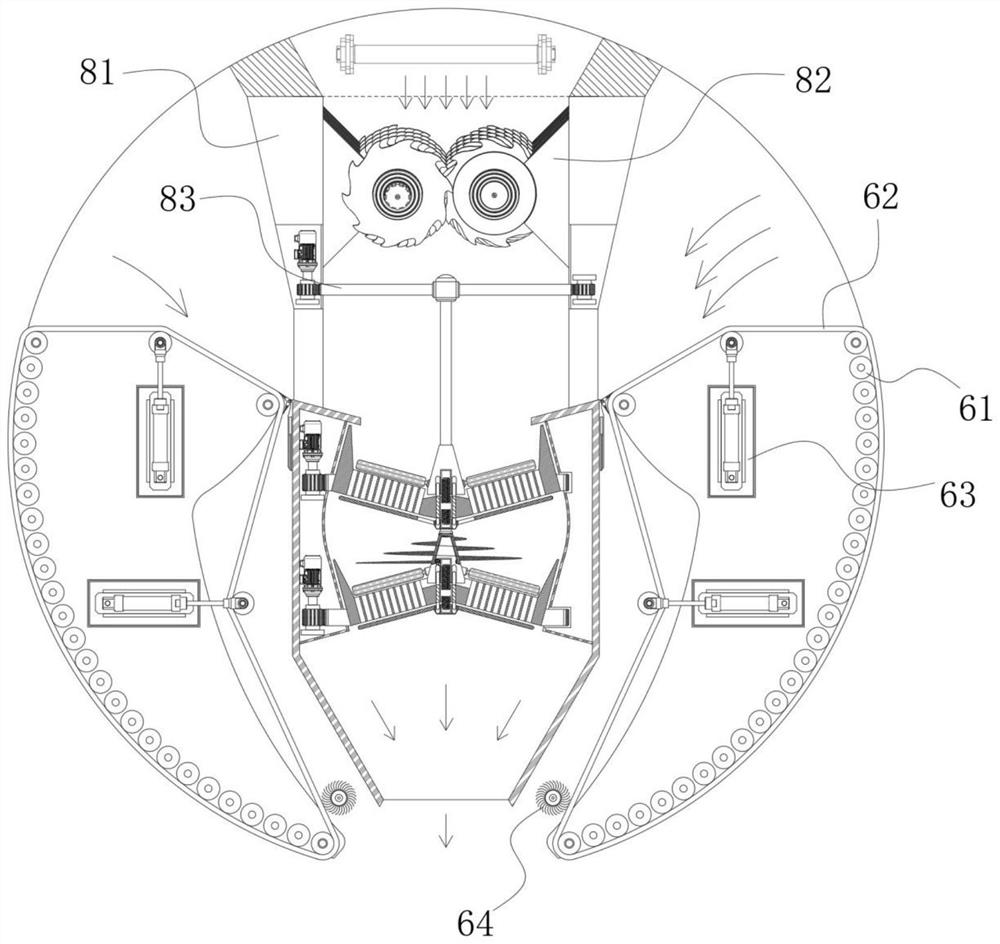

[0050] The screening ring box 3 is embedded in the annular shell 4 and is rotatably connected. The outer left ring wall is provided with an outer rotation sealing assembly 9, and the inner ring wall is provided with an inner rotation sealing assembly 6. Two groups are arranged symmetrically on the left and right. ;

[0051] The grinding device 8 is arranged in the screening ring box 3 and is sandwiched between the inner rotating seal assemblies 6 on the left and right sides.

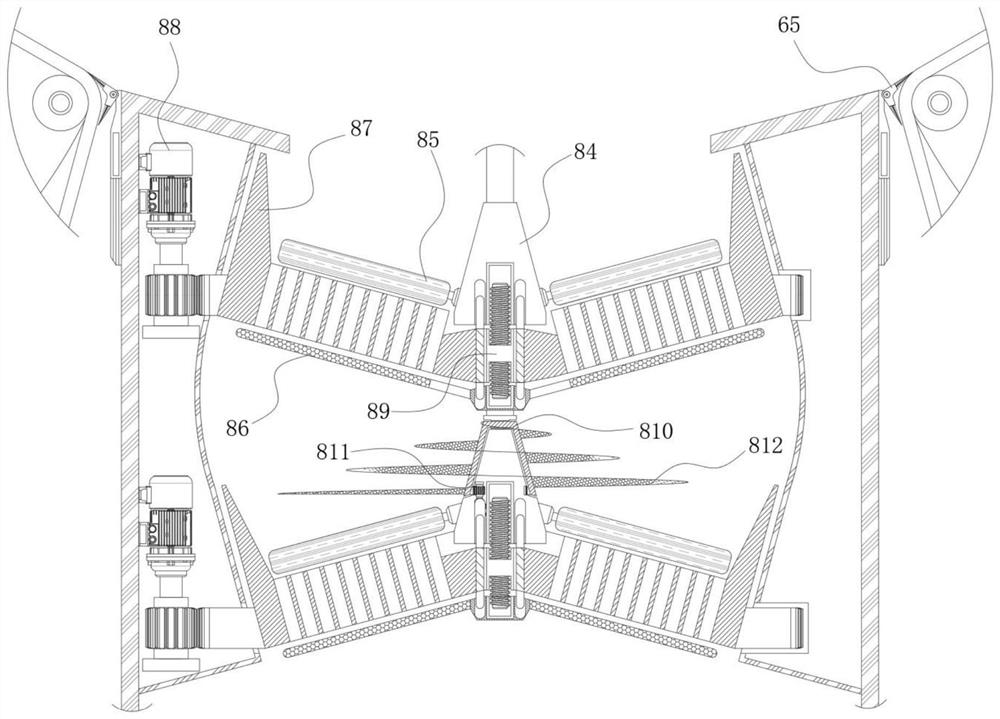

[0052] In this embodiment, the grinding device 8 includes:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com