Casting sand recycling treatment system

A technology of recycling and casting sand, which is applied in the field of metal parts, can solve problems affecting the quality of sand molds, and achieve the effect of improving the screening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is attached Figure 1-5 The application is described in further detail.

[0034] The embodiment of the present application discloses a casting sand recycling and processing system.

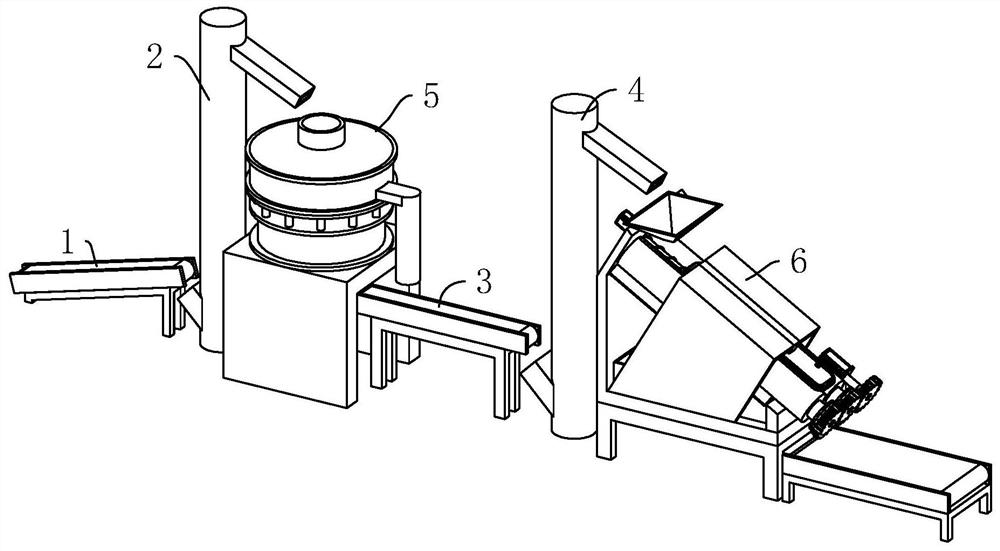

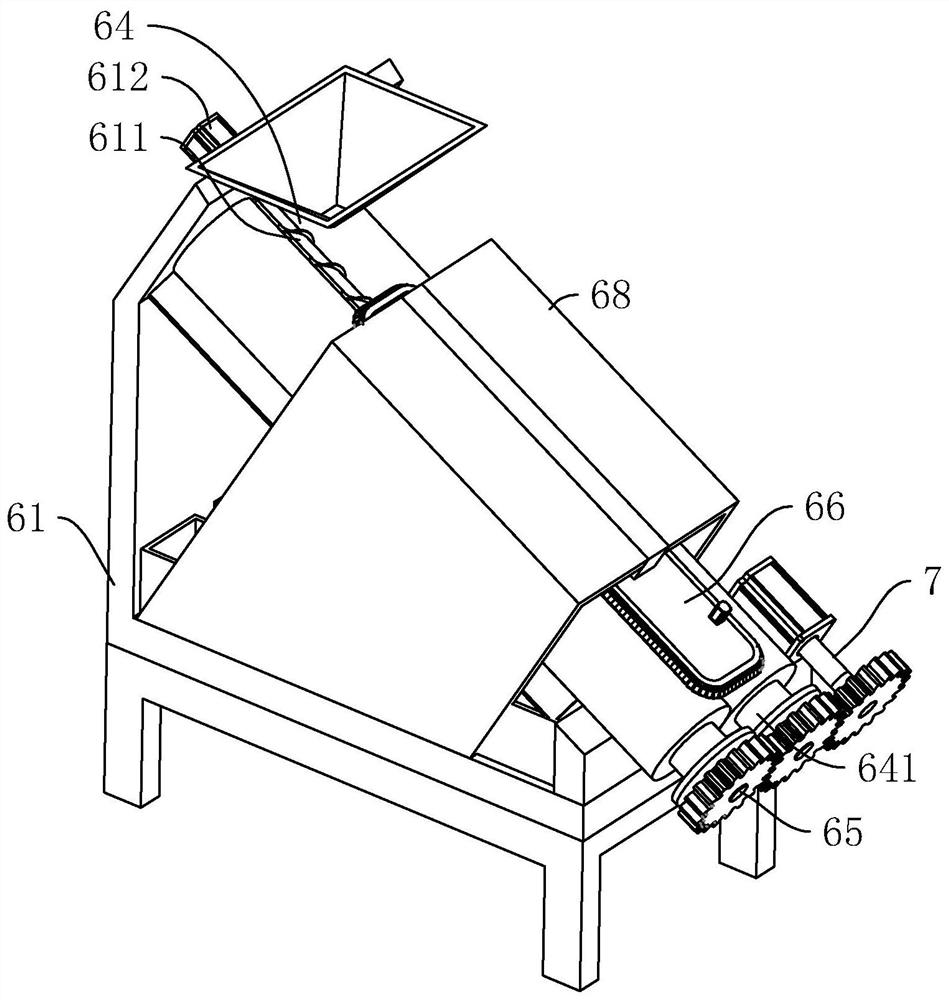

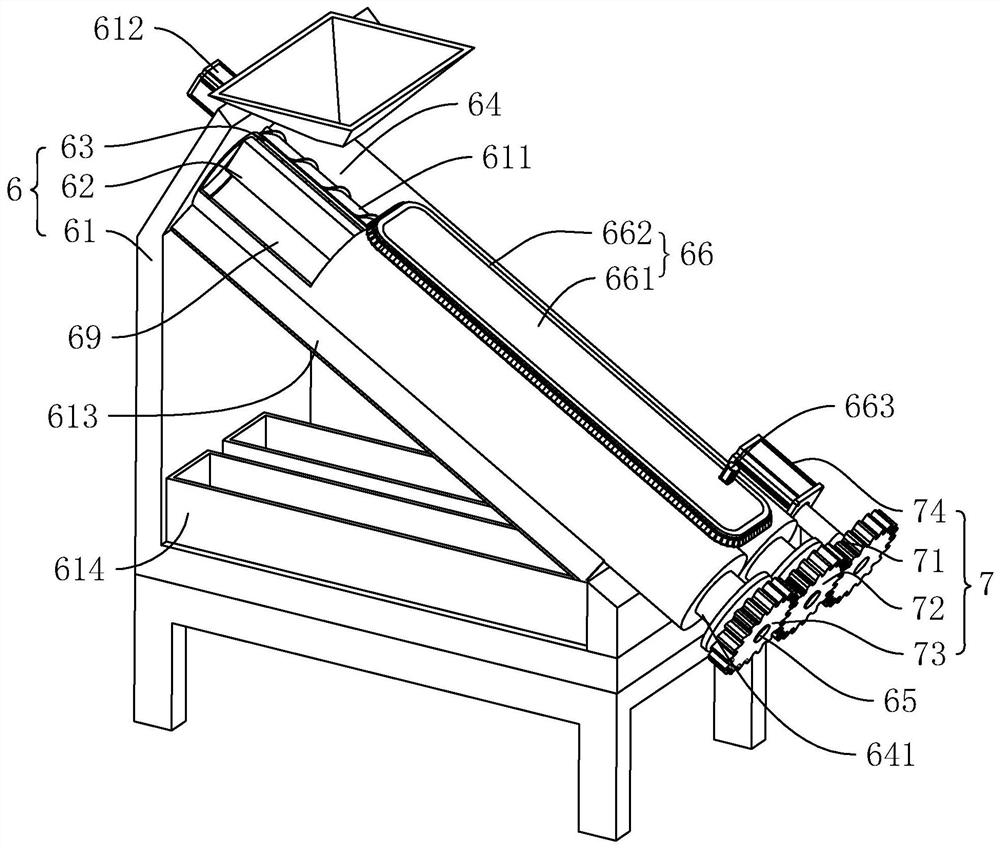

[0035] refer to figure 1 , a foundry sand recovery treatment system, comprising a conveyor belt 1, a hoist 2, a conveyor belt 2 3, a hoist 2 4, a vibrating screen machine 5 and a screening device 6, a conveyor belt 1, a hoist 2, a vibrating Screening machine 5, conveyor belt 2 3, hoist 2 4, and screening device 6 are sequentially arranged along the conveying direction of casting sand.

[0036] Conveyor belt one 1 is used to transfer the crushed casting sand to the feed inlet of hoist one 2, after hoist one 2 lifts the casting sand to a high place, the discharge port of elevator one 2 is located in the vibrating screen machine Above the feed port of 5, the casting sand will fall into the vibrating screen machine 5 after being passed out from the discharge port, and the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com