Concrete floor pouring mold and construction method thereof

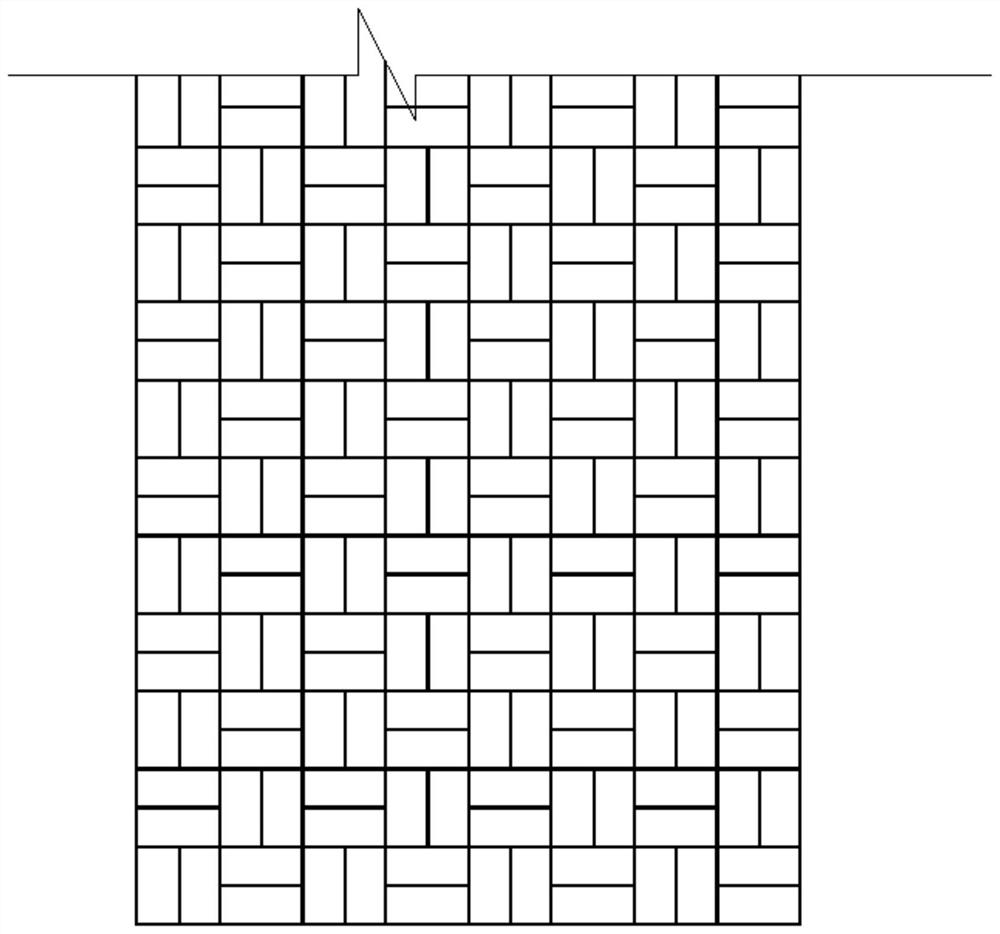

A technology for pouring molds and construction methods, applied in construction, building construction, etc., can solve problems such as inability to meet outdoor/internal floor diversity construction requirements, high flatness control requirements, stone cracks and joints, etc., and achieve high construction efficiency. , The effect of less quality defects and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

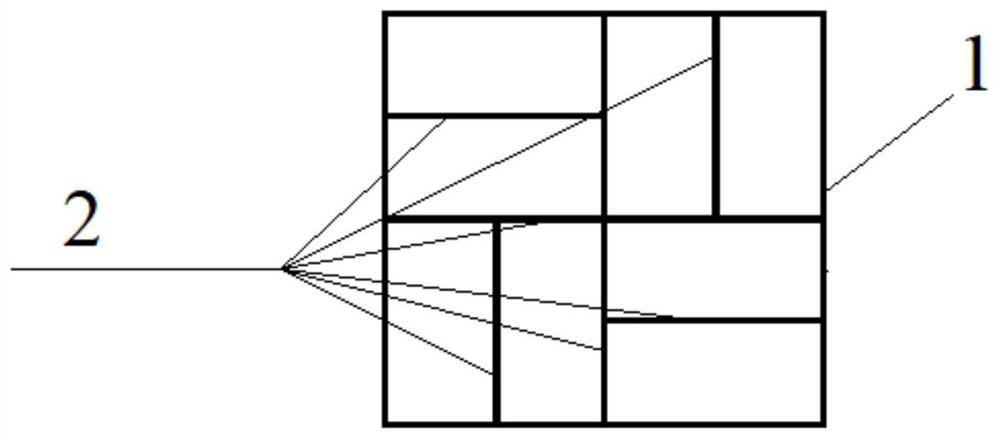

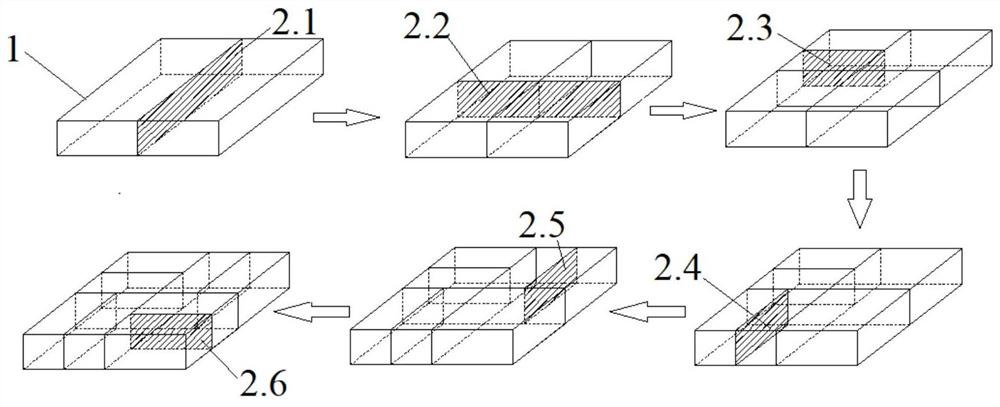

[0036] A concrete ground pouring mold, such as Figure 2~3 As shown, the mold frame 1 (made of stainless steel) and the separator 2 (made of stainless steel) comprising a square tubular structure are included;

[0037] The mold outer frame 2 matches the outer contour of a single paving unit;

[0038] There are six partitions 2 and they are arranged in the mold outer frame 1. The first partition 2.1 and the second partition 2.2 are perpendicular to each other and divide the mold outer frame 1 into four square areas with equal areas. Each square area A partition (including the third partition 2.3, the fourth partition 2.4, the fifth partition 2.5, and the sixth partition 2.6) that evenly divides the square area is arranged inside, and the partitions of adjacent square areas are perpendicular to each other, and each partition The layout of the boards is separated and matched with each part of the single paving unit. Between the partitions 2, the partition 2 and the mold frame 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com