Monostable magnetic suspension type damping device and calculation method of magnetic suspension force of monostable magnetic suspension type damping device

A vibration reduction device and magnetic levitation technology, which is applied in the direction of shock absorbers, magnetic springs, inertial effect shock absorbers, etc., can solve the problems of excessive modification of the main structure, limited application environment, unfavorable universalization, etc., and achieve the effect of vibration reduction Improve and reduce the volume of the space, which is beneficial to the effect of miniaturization design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and examples. It should be noted that although the accompanying drawings in the description describe the embodiment, the implementation is only illustrative rather than restrictive. Without departing from the gist of the present invention and the protection scope of the claims, the materials and dimensional parameters of each component can also be changed, and these all belong to the protection scope of the present invention.

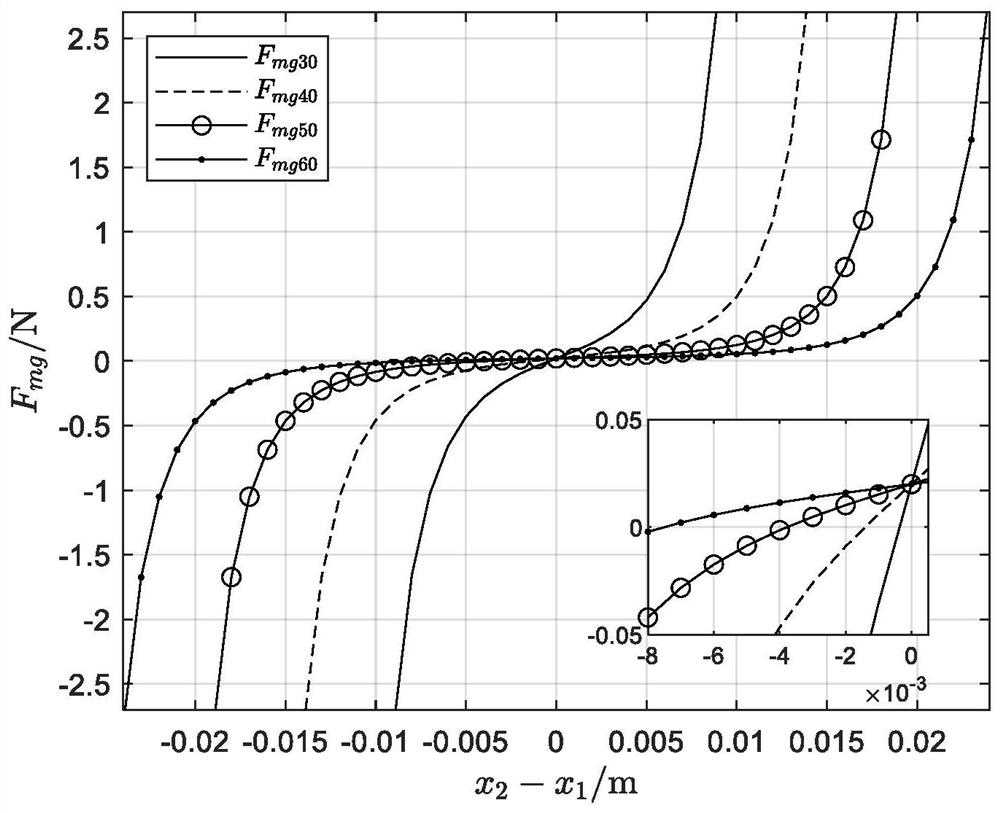

[0038] The technical solution includes the structure of the monostable magnetic levitation damping system, the connection mode and connection position of the shock absorber and the cantilever beam, the calculation steps of the monostable magnetic levitation force in the shock absorber, and the calculation method of the optimal magnet spacing in the shock absorber.

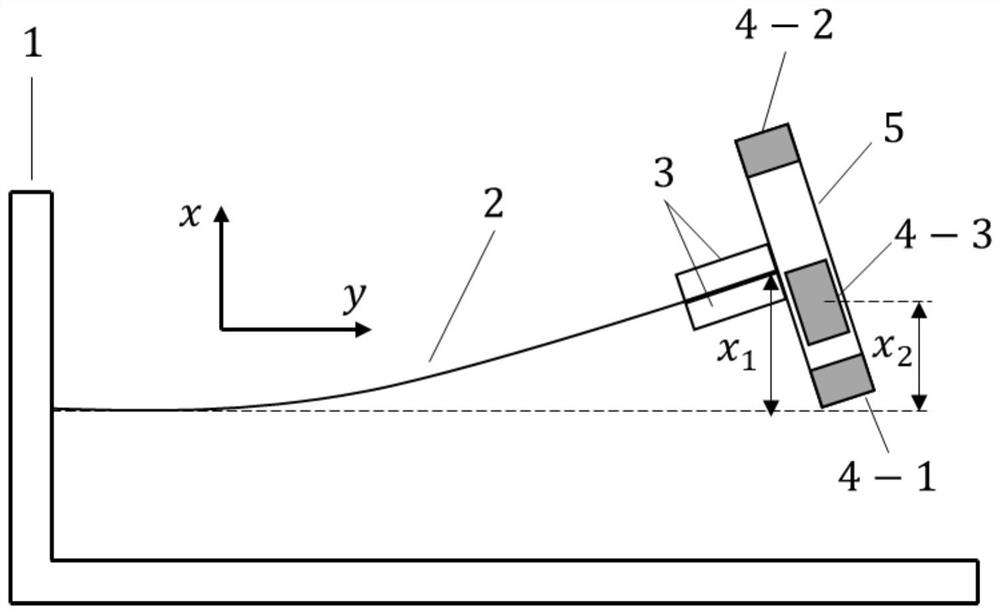

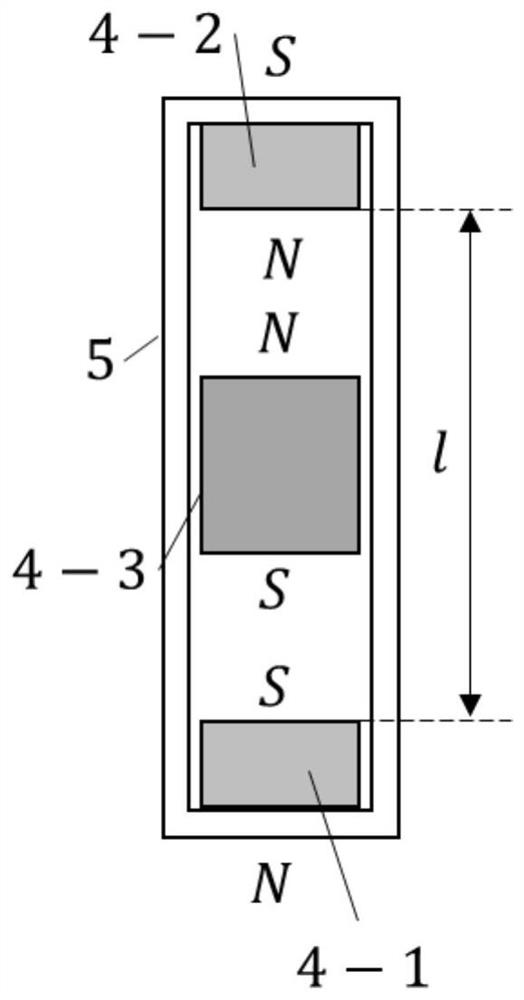

[0039] combined with figure 1 And attached figure 2 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap