Hydraulic high-precision automatic leveling device with self-locking function

An automatic leveling, hydraulic technology, applied in the direction of mechanical equipment, engine frame, non-rotational vibration suppression, etc., can solve the problems of leveling failure, mechanical equipment rollover, low precision, etc., to save manual adjustment, prevent Damage, the effect of high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

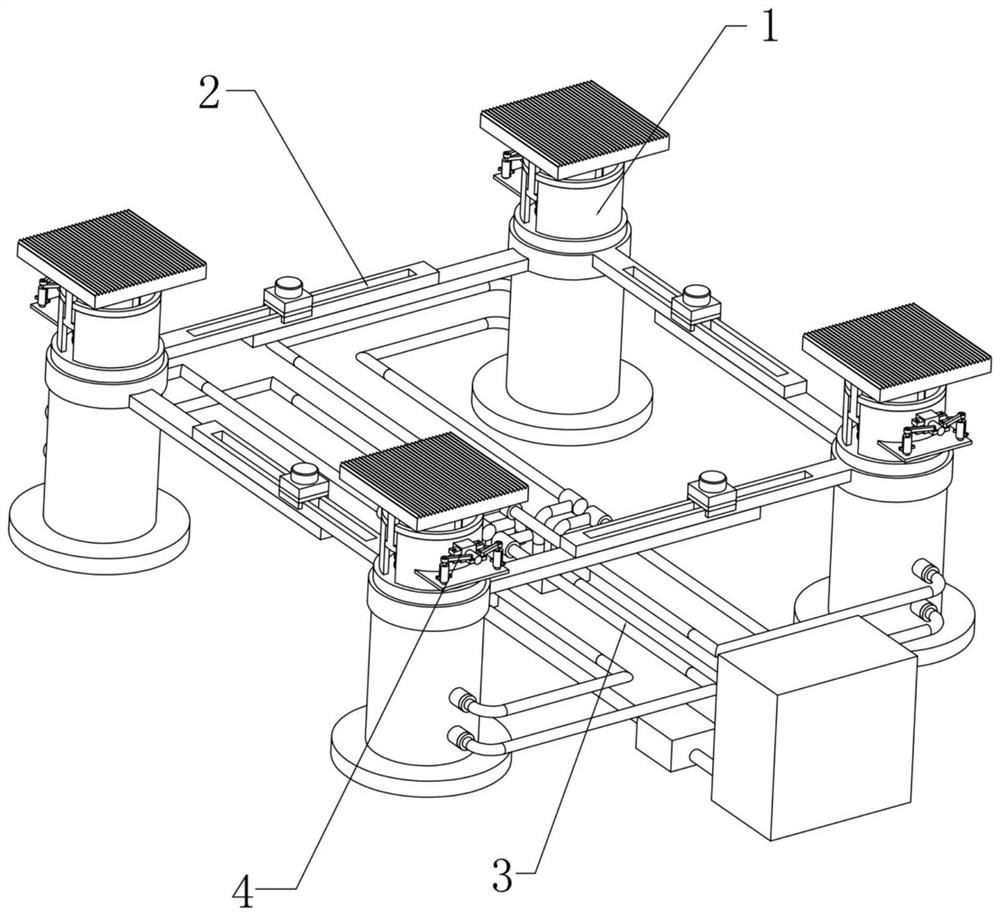

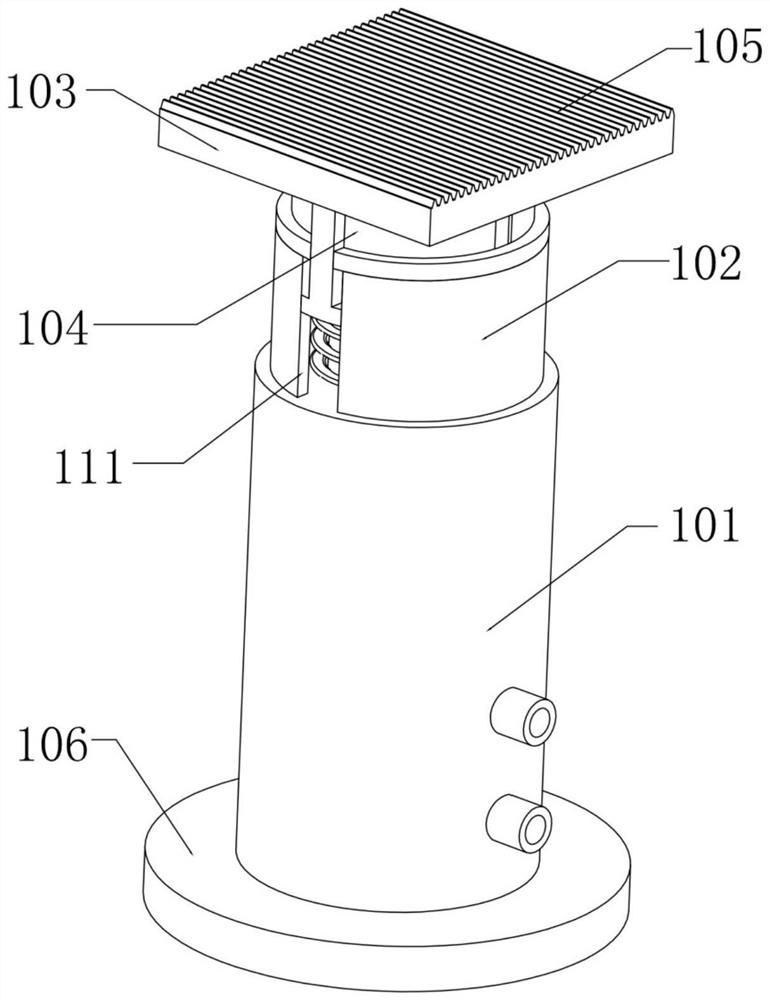

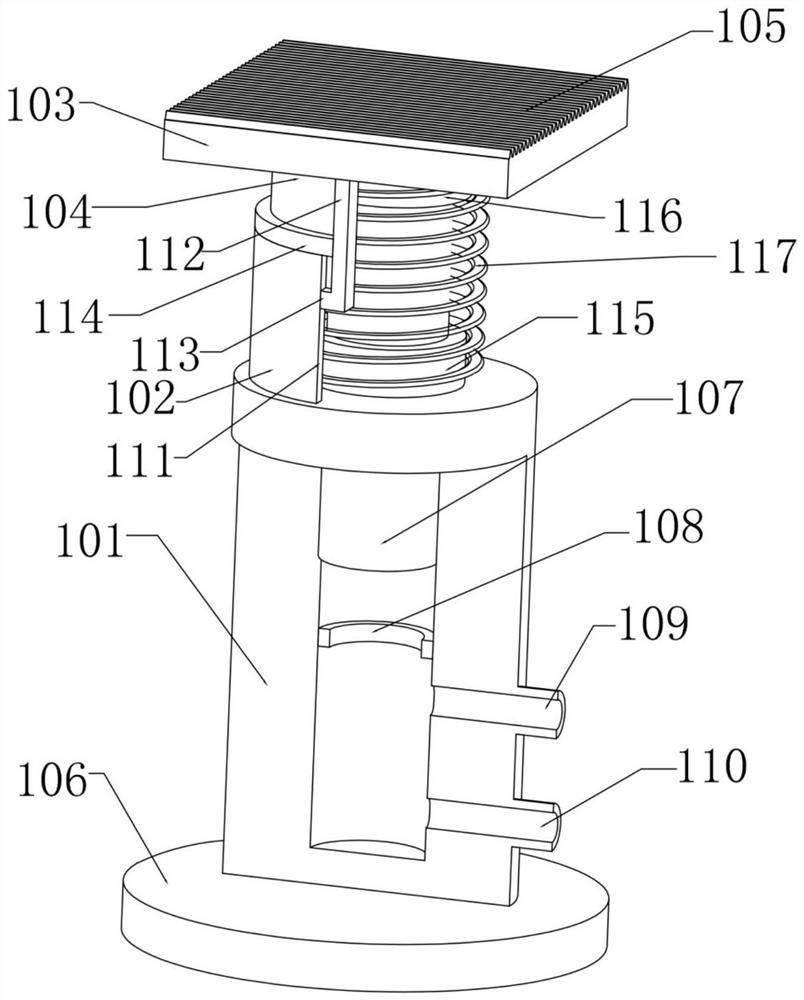

[0038] Examples of automatic leveling of mechanical equipment carried by the present invention are as follows: figure 1 , image 3 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the four sets of leveling assemblies 1 are respectively arranged at the corners of the automatic leveling device, and the whole is fixed on the operation plane by the fixed base 106, and the lifting limit base 102 of a cylindrical structure is fixed on the outer side of the top of the oil cylinder main body 101, Both ends of the lifting limit base 102 are symmetrically provided with lifting grooves 111, and a lifting shaft 104 is fixed on the outside of the bottom of the leveling top plate 103. Seat 112, the card platform 113 is fixed on the bottom of the lifting seat 112, and the card platform 113 can slide up and down in the lifting groove 111. The top limit position 114 is fixed on the top of the lifting limit base 102, and the top limit position 114 presses the card platform 113 on th...

Embodiment 2

[0046] The present invention realizes the mechanical locking of the leveling top plate 103 in each group of leveling assemblies 1 after the leveling is completed. figure 1 , figure 2 , Figure 4 , Figure 10 , Figure 11 with Figure 12 As shown, the outer side of the lifting limit base 102 in each group of leveling assemblies 1 is provided with a locking assembly 4 for locking the leveling top plate 103, the locking groove 401 is opened on the outer wall of the lifting shaft 104, and the lifting limit base 102 On the position corresponding to the outer wall and the locking groove 401, a locking position 402 is provided, and a locking cylinder 403 is inserted into the locking position 402. The front end of the locking cylinder 403 can be pressed against any position in the locking groove 401. Symmetrically fixed fixed rotation 404, the left and right sides of the rear end of the lock cylinder 403 are symmetrically fixed with linkage rotation 405, each set of fixed rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com