Method for controlling silane to be on line

A silane, manual control technology, applied in the container discharge method, container filling method, equipment discharged from the pressure container, etc., can solve the safety risk and other problems, and achieve the effect of solving the system stamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The method for controlling silane on-line includes automatic control and manual control, and its automatic control includes the following steps:

[0037] A1. Open the safety lock of the pneumatic valve on the silane line;

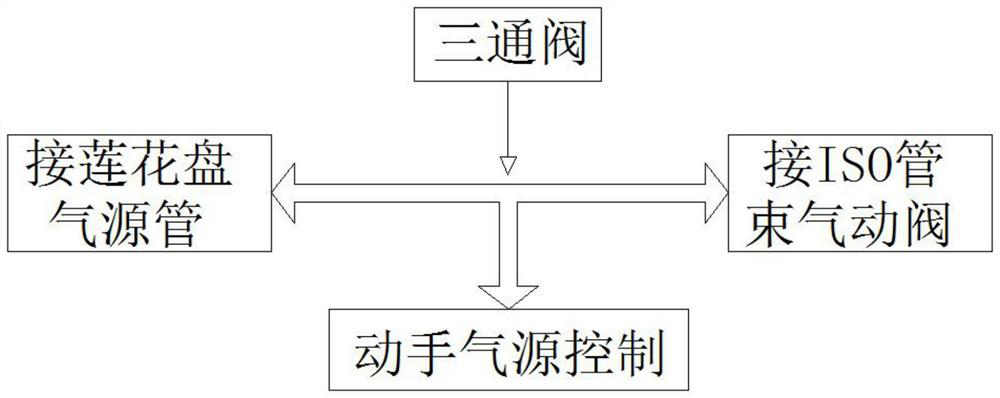

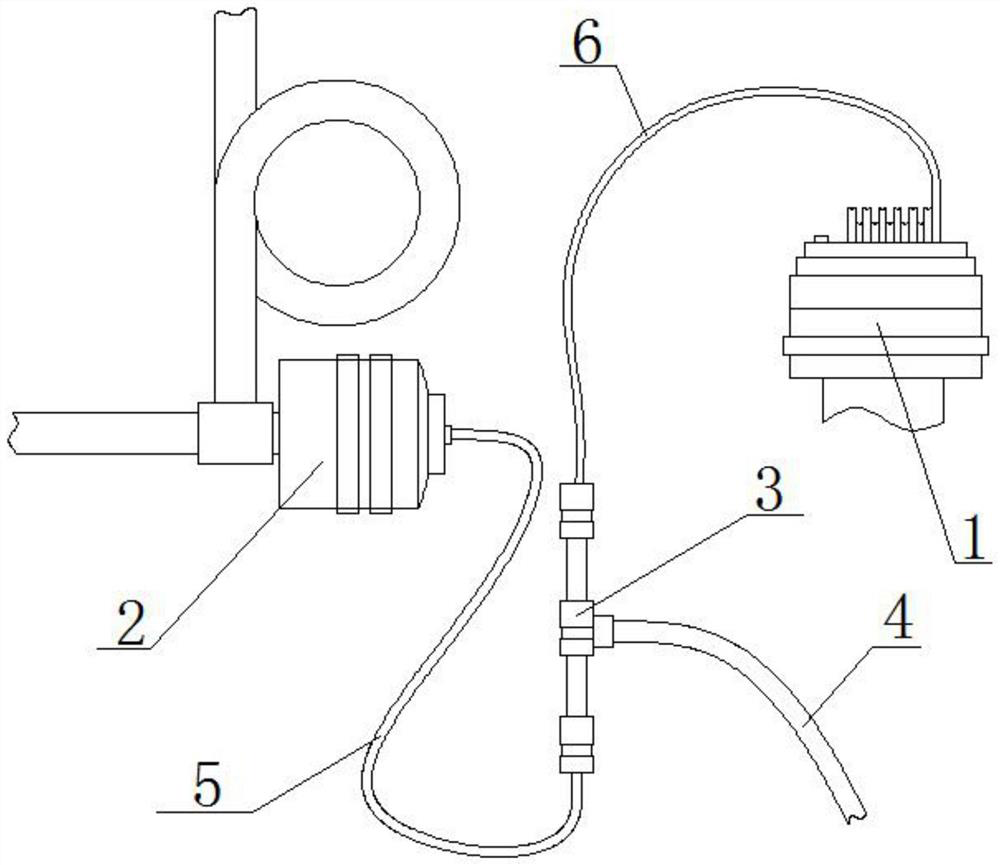

[0038] A2. Insert the silane gas pipe into the starting valve to form pressure. Insert the silane gas pipe into the starting valve to form the pressure. The method of forming pressure is: when the ISO tube bundle pneumatic valve 2 is open, the normally open pipe 4 is blocked. At this time, the lotus Pan gas source 1, connected to the ISO tube bundle pneumatic valve 2, are connected together, and the pressure is formed to open the valve;

[0039] A3, system control switch;.

Embodiment 2

[0041] Its manual control includes the following steps:

[0042] B1. First connect all the pipes,

[0043] B2. Manually control the normally open pipeline 4 to slowly open the ISO tube bundle pneumatic valve 2. In step B2 of the manual control process, when the ISO tube bundle pneumatic valve 2 is opened, the silane gas will slowly pass through, reducing the supply of silane gas and preventing the flow of silane The stamping produced during the operation will cause harm to the equipment.

[0044] The beneficial effects of the present invention are: the silane ISO vehicle is full of 4000kg, the pressure is about 1700psi in summer and 1400psi in winter, the system defaults, the valve opens instantly every time it goes online, there is a serious safety risk, and the manual control of pressure increase is good for the safety of the system For the control function, use the three-way valve 3 and the hose, connect the lotus disc interface to the side of the three-way valve 3, connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com