A waste gas processor for screening plastic paint raw materials

An exhaust gas processor and raw material technology, which is applied in the directions of vapor condensation, chemical instruments and methods, separation methods, etc., can solve problems such as affecting purification treatment work, incomplete gas-liquid separation, and inability to realize exhaust gas output, and achieves a high emission rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

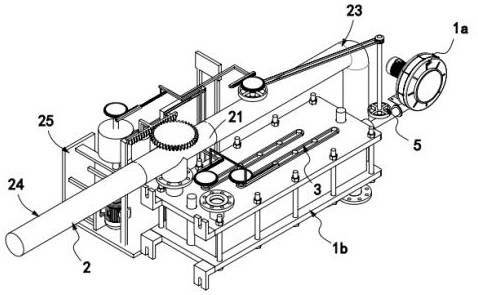

[0046] Such as figure 1 As shown, an exhaust gas processor used for screening plastic paint raw materials includes a blower device 1a and a heat exchange device 1b arranged on one side of the blower device 1a, and also includes a device connected to the heat exchange device 1b. And the control mechanism 2 for automatically diverting the exhaust gas at different temperatures and the green temperature control mechanism 3 arranged in the heat exchange device 1b and driving along the length direction of the heat exchange device 1b;

[0047] The control mechanism 2 includes a transfer pipe 21 arranged on the upper end of the heat exchange device 1b, an adapter plate 22 installed in the center of the transfer place of the transfer pipe 21, one end communicates with the transfer pipe 21 and the other end communicates with the transfer pipe 21. The automatic flow guide mechanism 23 provided in communication with the heat exchange device 1b, the output mechanism 24 provided in communicat...

Embodiment 2

[0075] Such as Figure 6As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

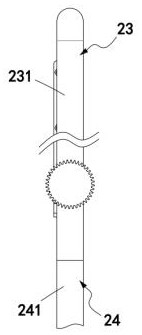

[0076] further, such as Figure 6 As shown, the automatic flow guide mechanism 23 includes a first delivery channel 231 and a second regulating valve 232 installed on the first delivery channel 231 and used to control the air volume of the first delivery channel 231;

[0077] The second regulating valve 232 works synchronously with the power transmission mechanism 25 through the second linkage assembly 233 .

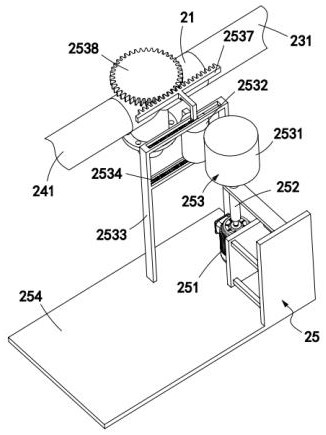

[0078] further, such as figure 2 As shown, the second linkage assembly 233 includes:

[0079] The driving wheel 234, the driving wheel 234 is coaxial and fixedly connected with the drive shaft 252;

[0080...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com