A method for recovering waste gas from the production of soft-touch leather coatings

A leather coating and exhaust gas recovery technology, applied in the field of soft-touch leather coatings, can solve the problems of poor cooling environment and substandard exhaust gas temperature, and achieve the effect of increasing discharge volume and sufficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

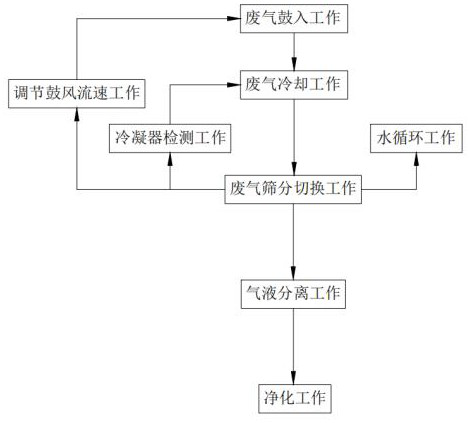

[0081] Such as figure 1 As shown, a method for recovering waste gas from the production of soft-touch leather coatings, including:

[0082] In the first step, the waste gas is blasted into the work, and the waste gas containing heat is blown into the heat exchanger 1b through the fan 1a;

[0083] The second step is exhaust gas cooling. The heat-containing exhaust gas performs preliminary cooling of the exhaust gas in the heat exchanger 1b. The exhaust gas is transported in an S shape under the action of the first rotating assembly 31a and the second rotating assembly 31b in the heat exchanger 1b. Inside, the condensed liquid is finally collected from the liquid outlet, and the exhaust gas passing through the heat exchanger 1b is transmitted to the three-way output;

[0084] The third step is to switch over the waste gas screening. When the temperature control accuracy meter detects that the temperature of the air flow output from the heat exchanger 1b is higher than a certain...

Embodiment 2

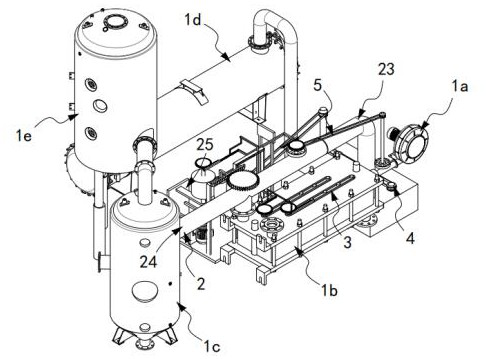

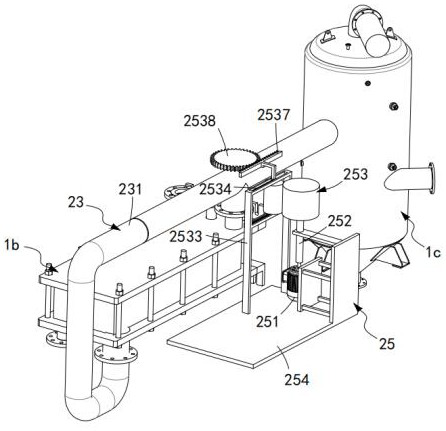

[0102] Such as figure 2 As shown, the industrial waste gas high-efficiency recovery system includes a fan 1a, a heat exchanger 1b, a rotary separator 1c, a cooling tower 1d, and a gas-liquid mixing tower 1e. The exhaust gas is directed to the switching mechanism 2 for automatic flow splitting, the cooling mechanism 3 arranged in the heat exchanger 1b and driven along the length direction of the heat exchanger 1b, and used to control the heat exchanger 1b and the rotary separator 1c The heat dissipation mechanism 4 for pre-cooling the water after internal heating, the water outlet 4a of the heat dissipation mechanism 4 is communicated with the cooling tower 1d and its water inlet 4b is communicated with the heat exchanger 1b;

[0103] The switching mechanism 2 includes a tee 21 arranged on the upper end of the heat exchanger 1b, a switching plate 22 installed in the center of the transition of the tee 21, one end communicates with the tee 21 and the other end communicates with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com