Waxing device for solid wood furniture production

A furniture and solid wood technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of inability to guarantee the quality of hot wax, uneven wax application, and reduced performance, so as to reduce manual labor and apply quickly. The effect of uniform and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

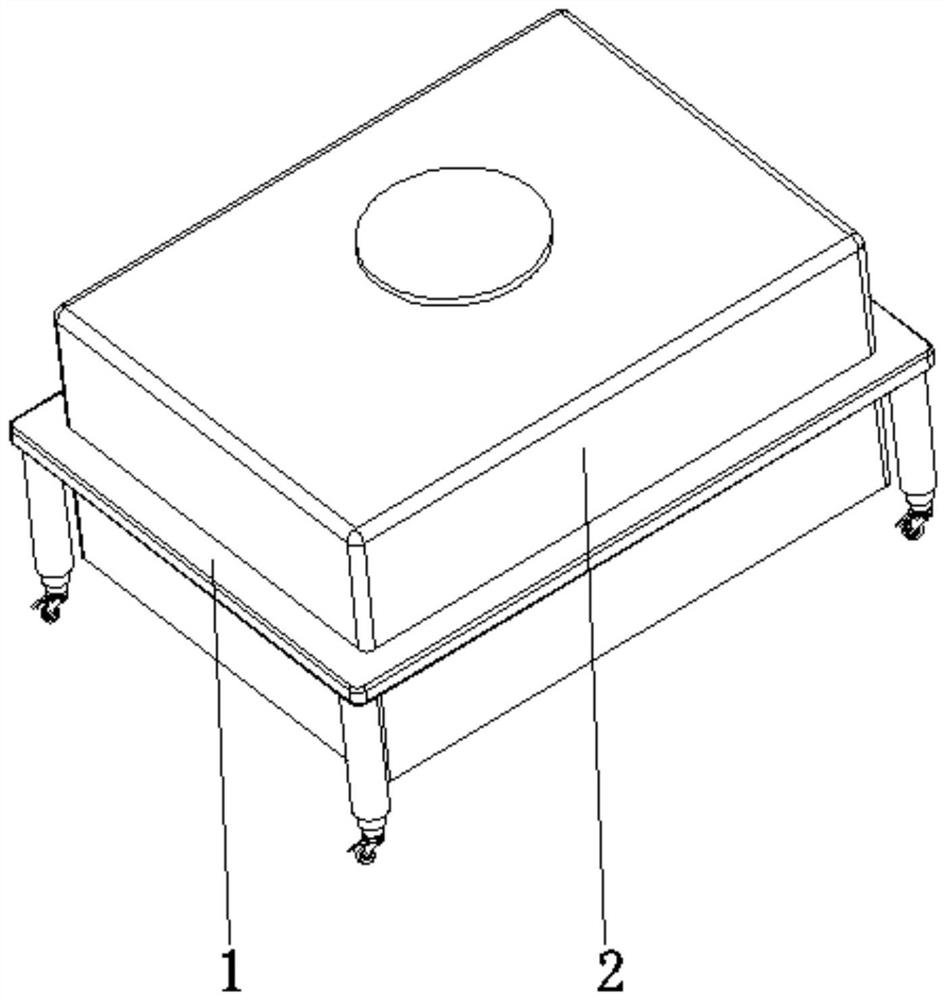

[0030] see Figure 1-6 , the present invention provides a technical solution: a waxing device for solid wood furniture production, comprising a lifting frame 1 and a box body 2, the surface of the box body 2 is fixedly connected to the top of the lifting frame 1;

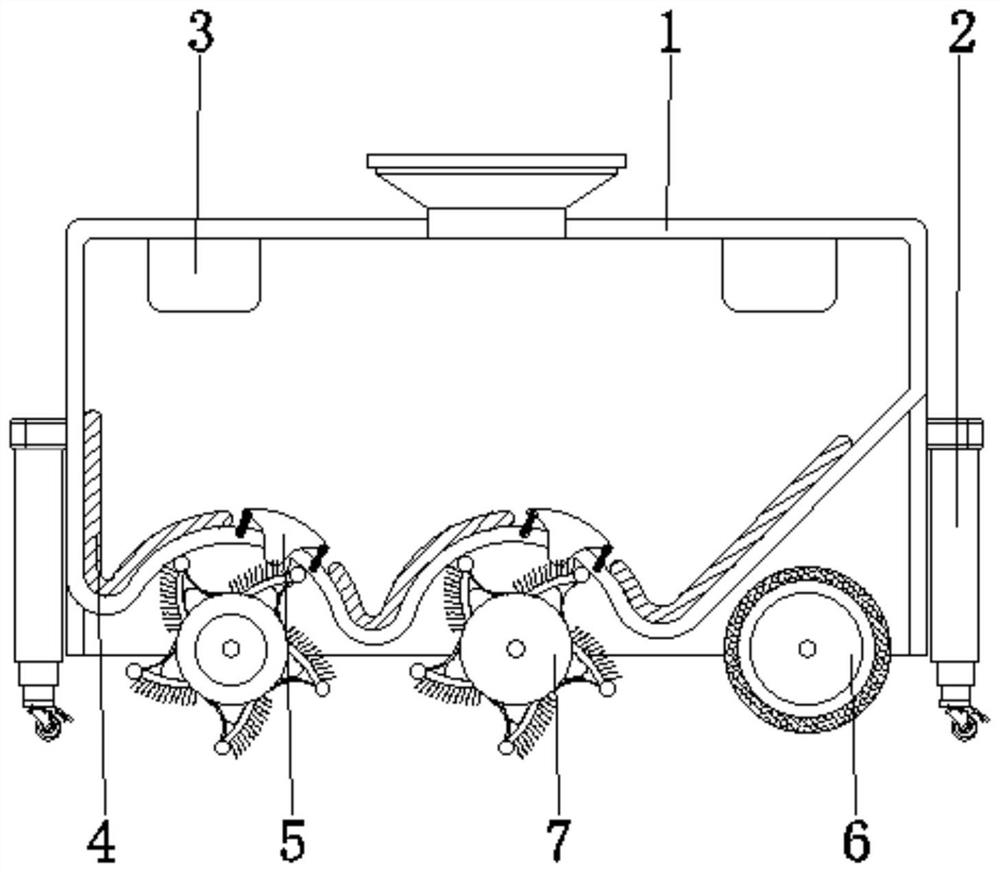

[0031] The inside of the box body 2 is provided with a booster mechanism 3, a heater 4, a plugging device 5, a polishing roller 6, and a brush roller device 7. The booster mechanism 3 is arranged on the top of the inner wall of the box body 2, and the heater 4 is arranged on the 2, the blocking device 5 is arranged at the bottom of the inner wall of the box body 2 and is located at the position of the heater 4, the polishing roller 6 is arranged inside the box body 2 and is located at the bottom side, and the brush roller device 7 is arranged at the box body 2 Inside and located at the bottom position, the brush roller device 7 is connected with the sealing device 5, which can be adapted to mass production, reduces ...

Embodiment example 2

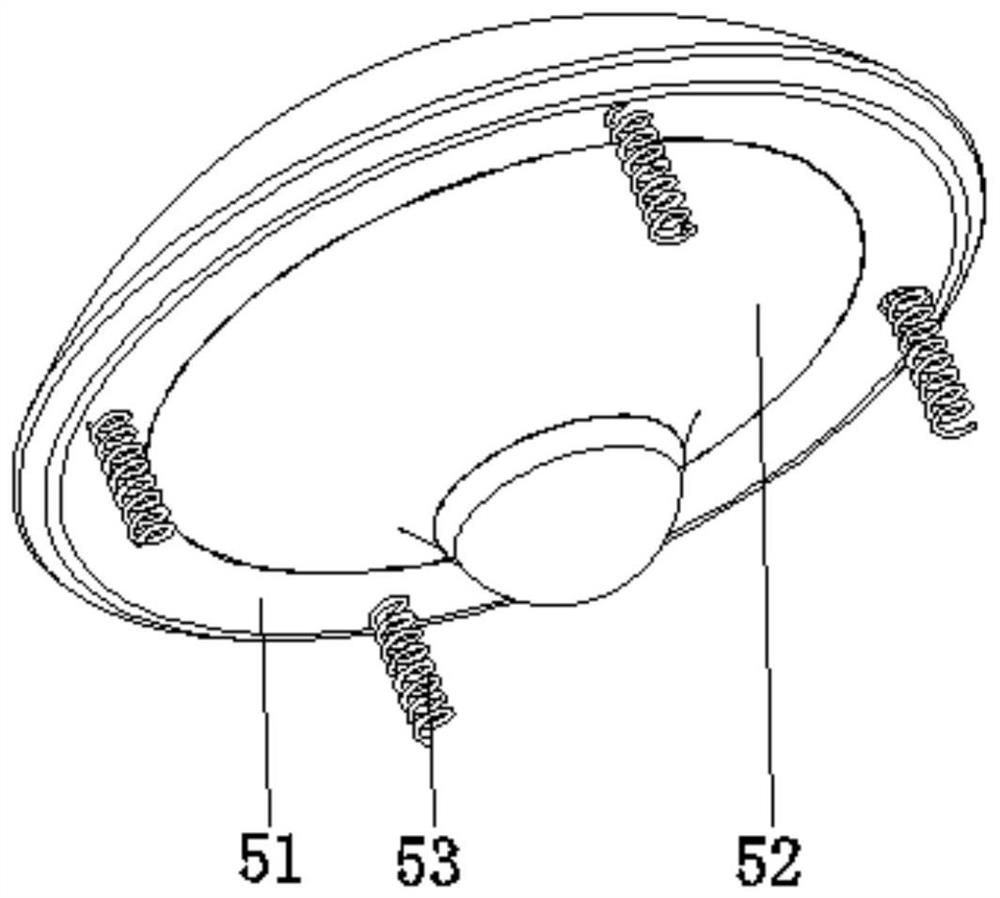

[0033] The plugging device 5 is provided with an arc-shaped ball plug 51, a gasket 52, and a back-moving spring 53. The arc-shaped ball plug 51 is arranged in the inside of the casing 2 and is located at the bottom position. The surface bottom of the arc-shaped ball plug 51 is in contact with the box The bottom of the inner wall of the body 2 is mated and connected, the gasket 52 is arranged on the bottom of the surface of the arc-shaped ball plug 51, and the return spring 53 is fixed between the bottom edge of the surface of the arc-shaped ball plug 51 and the two sides corresponding to the bottom of the inner wall of the box body 2 , using the rotation of the brush roller device 7, intermittently press the arc-shaped ball plug 51, and under the elastic force of the return spring 53, the arc-shaped ball plug 51 is opened and closed reciprocatingly, and at the same time when the arc-shaped ball When the plug 51 is opened, the inside of the box body 2 is pressurized by the press...

Embodiment example 3

[0035] The brush roller device 7 is provided with a driving shaft 71, a roller body 72, and a beeswax brushing device 73. The driving shaft 71 is arranged at the bottom position of the casing 2, and one end of the driving shaft 71 is rotationally connected with the inner wall of the casing 2, and the roller body 72 is fixed. At the end of the driving shaft 71 away from the inner wall of the casing 2, the beeswax brushing device 73 is arranged on the surface of the roller body 72. When the driving shaft 71 drives the roller body 72 to rotate, the beeswax brushing device 73 will also rotate thereupon. When the end of the beeswax brushing device 73 in rotation is in contact with the plugging device 5, the arcuate ball head plug 51 can be pressed, and then the effect of opening the liquid spray can be realized. Now, the beeswax brushing device 73 after the liquid spray And in the case of rotation, the furniture is quickly waxed, and then through the interaction of the structure, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com