Internet-of-Things remote factory prefabricated part production control system and method for energy station

A production control and remote technology, applied in the field of factory prefabricated parts production control system for remote energy stations of the Internet of Things, can solve the deformation of the position of the steel pipe and the flange, the bolt holes cannot be accurately located in the concentric position, and the positioning error is large, etc. problem, to achieve the effect of preventing position deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

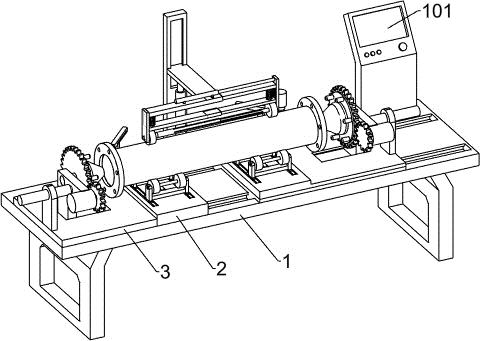

[0032] A factory prefabricated production control system for remote energy stations of the Internet of Things, including a support plate 1, an on-site control terminal 101, a remote control terminal 102, a data storage module 103, a network transmission 104, an adjustment module 105, a steel pipe rotation module 106, Flange push module 107, flange rotation module 108, welding module 109, steel pipe support mechanism, flange control mechanism, welding mechanism, steel pipe rotation mechanism and the second electric slide table 6, the upper right part of the support plate 1 is provided with an on-site control Terminal 101, field control terminal 101 is connected to remote control terminal 102 through network transmission 104, data storage module 103 is electrically connected to remote control terminal 102, adjustment module 105, steel pipe rotation module 106, flange push module 107, flange rotation module 108 and the welding module 109 are electrically connected to the field con...

Embodiment 2

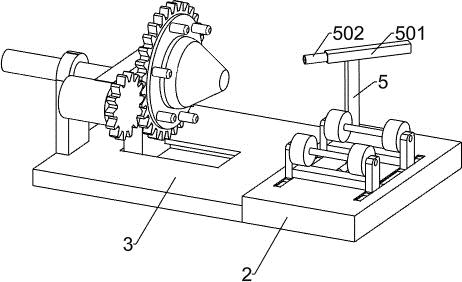

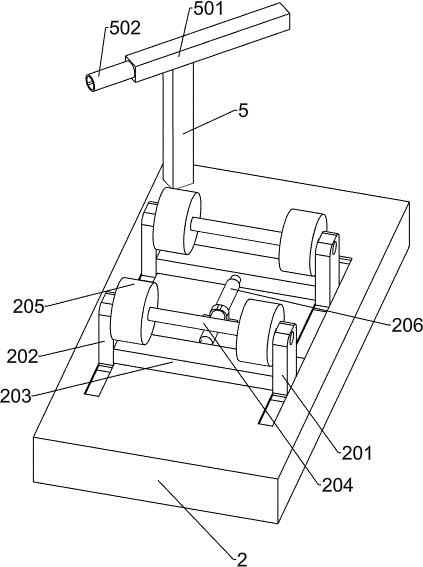

[0036] On the basis of Example 1, such as Figure 1-Figure 7 As shown, the steel pipe support mechanism includes a bottom plate 2, a steel pipe rotating frame and a two-way electric push rod 206, two slide grooves are arranged on the upper side of the bottom plate 2, two sets of steel pipe rotating frames are provided, and the two groups of steel pipe rotating frames are respectively slidably connected to the bottom plate Two chutes on the upper side of 2, the two-way electric push rod 206 is fixedly connected to the upper side of the bottom plate 2, the push rods at the front and rear ends of the two-way electric push rod 206 are respectively fixedly connected to two sets of steel pipe swivel frames, the two-way electric push rod 206 and the adjustment module 105 electrical connections, the steel pipe swivel frame includes a right vertical plate 201, a left vertical plate 202, a connecting plate 203, a rotating shaft 204 and a support wheel 205, and the right vertical plate 20...

Embodiment 3

[0044] On the basis of Example 2, such as Figure 1-Figure 7 As shown, when the flange is welded to the steel pipe, due to the local instantaneous high temperature of the steel pipe and the flange, the stress generated by the steel pipe and the flange cannot be released, resulting in the deformation of the positioning of the steel pipe and the flange, resulting in the deformation of the flange. When the flange and the steel pipe are deformed, after the positioning of the flange and the steel pipe is completed, the welding module 109 controls the welding mechanism to perform spot welding on the contact position between the flange and the steel pipe. After the spot welding is completed, the steel pipe rotation module 106 and the flange rotation module 108 control the steel pipe The rotation mechanism and the flange control mechanism rotate the flange and the steel pipe synchronously by 90 degrees, and the welding module 109 controls the welding mechanism to perform spot welding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com