Yarn frame for textile machine

A yarn rack and textile machine technology, applied in the textile field, can solve the problems of reducing processing efficiency, increasing processing procedures, affecting textile quality, etc., and achieving the effects of improving textile efficiency, ensuring stability, and reducing winding procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

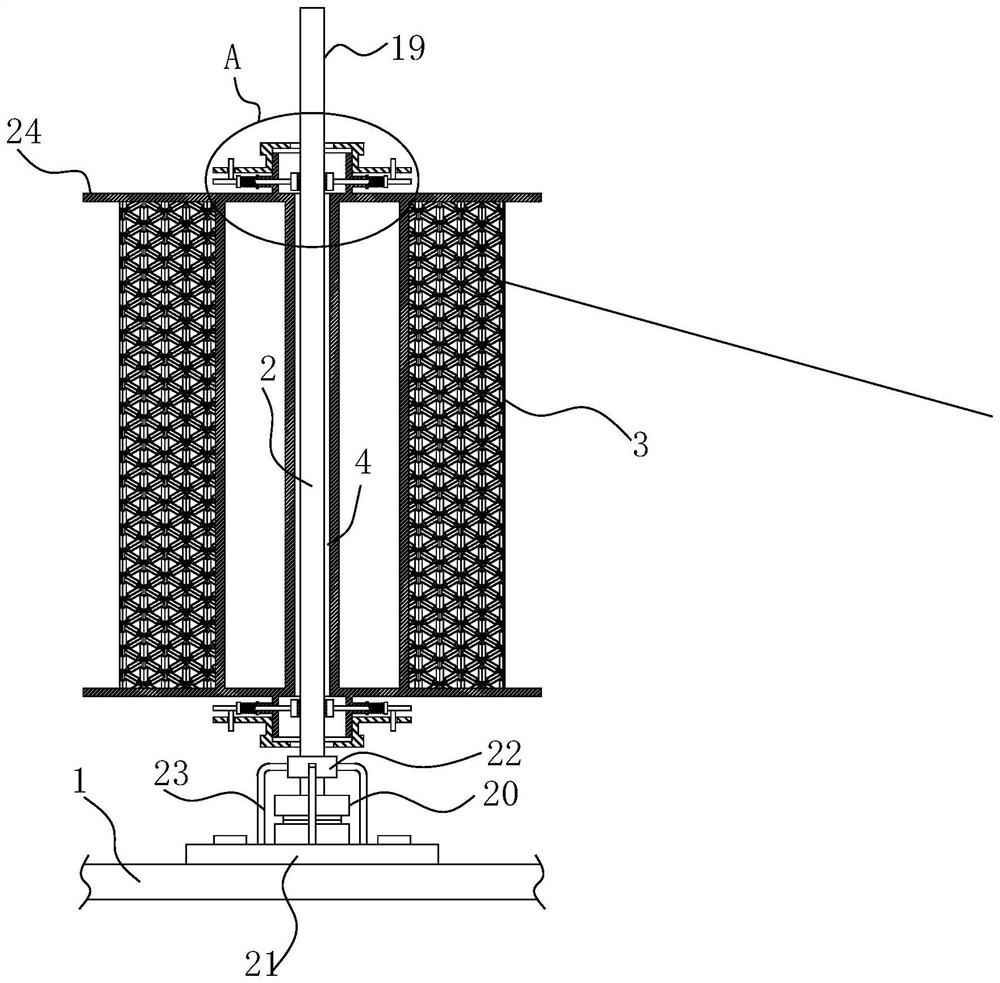

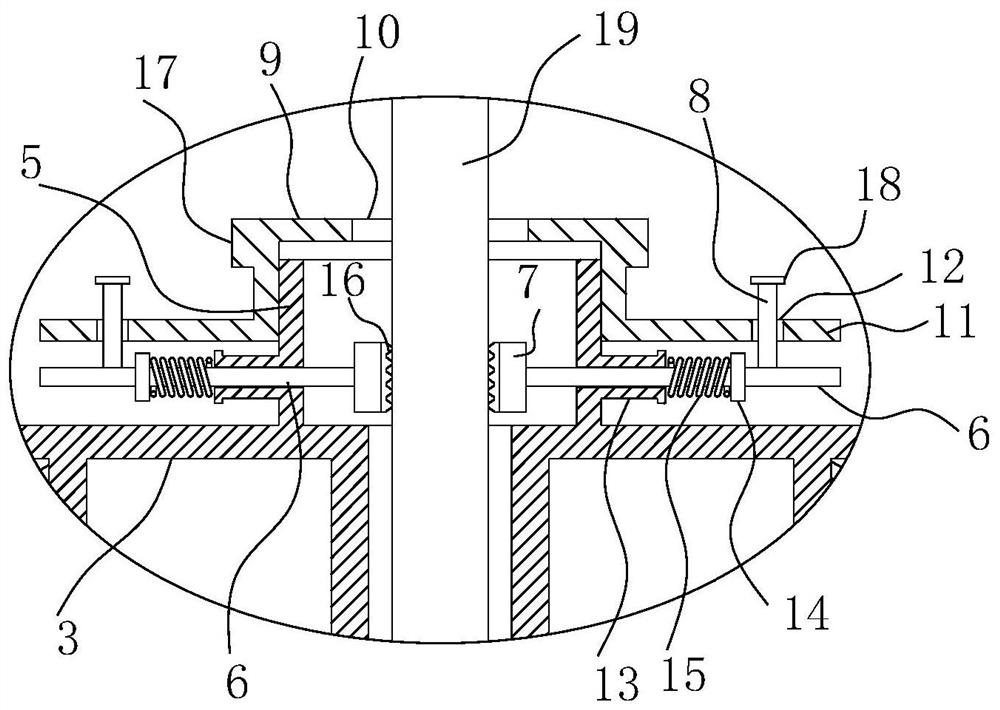

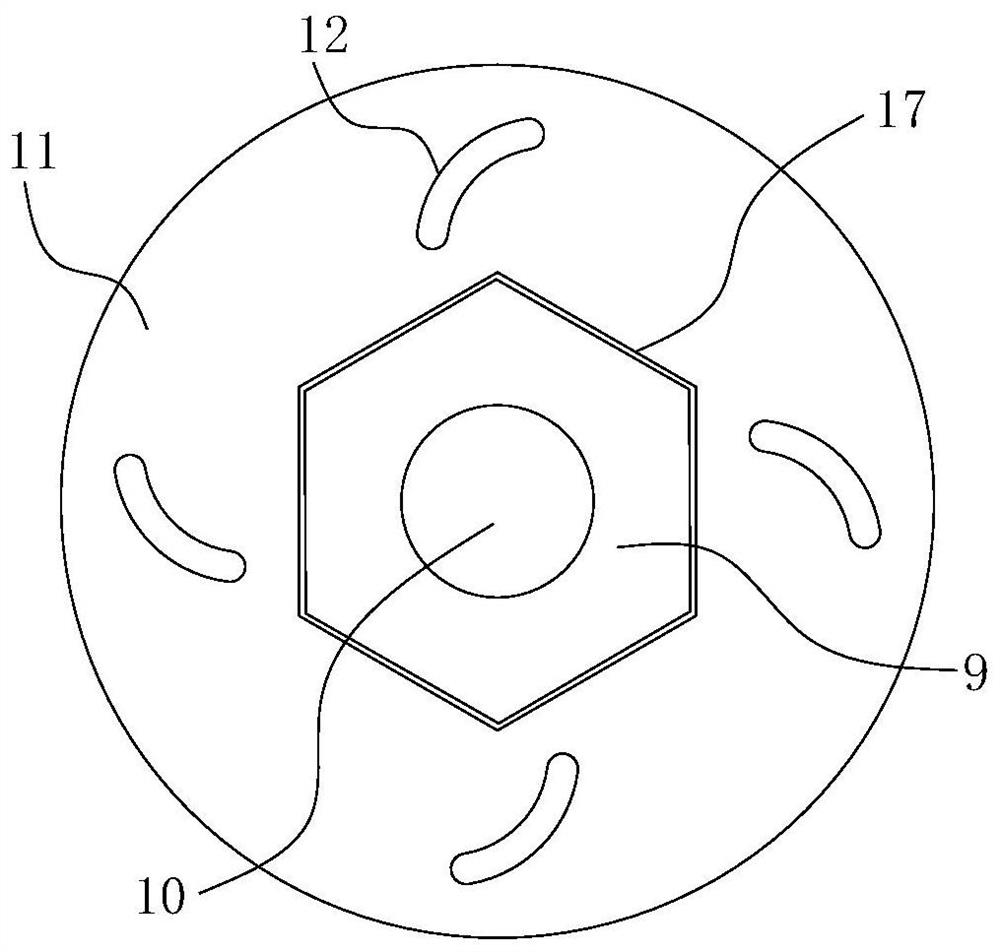

[0020] Such as Figure 1-3 As shown, a yarn frame for a textile machine includes a frame body 1, several rotating support rods 2 arranged on the frame body 1, and a yarn barrel. The frame body 1 adopts a conventional stainless steel frame body, and its structure is relatively conventional, which is not shown as a whole in the present invention. The rotating support rod 2 is arranged on the frame body 1 for installing the yarn drum. The simplest rotating support rod 2 is a rod body, which is connected to the frame body 1 through a rotary joint, but in order to facilitate the disassembly and assembly of the rotating support rod 2, a better way can be as follows figure 1 As shown in , the rotating support rod 2 includes a rod body 19, one end of the rod body 19 is connected to the base plate 21 through a rotary joint 20, and the base plate 21 is flange-connected to the frame body 1 to ensure the stability of the connection. Because the rod body 19 needs to support the weight of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com