SCR denitration urea hydrolysis ammonia production device

A urea hydrolysis and urea technology is applied in the field of flue gas denitrification, which can solve the problems of reducing the production efficiency of enterprises and reducing the service life of the ammonia gas separation system, and achieves the effects of improving the service life, avoiding the possibility of idling, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

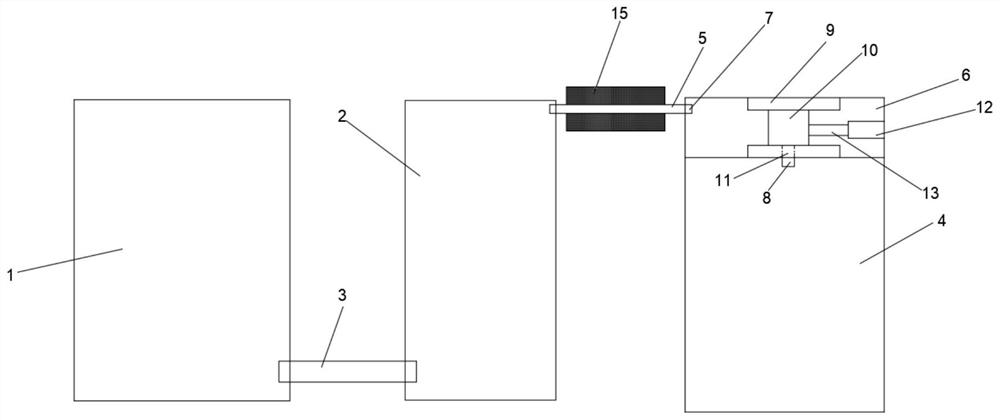

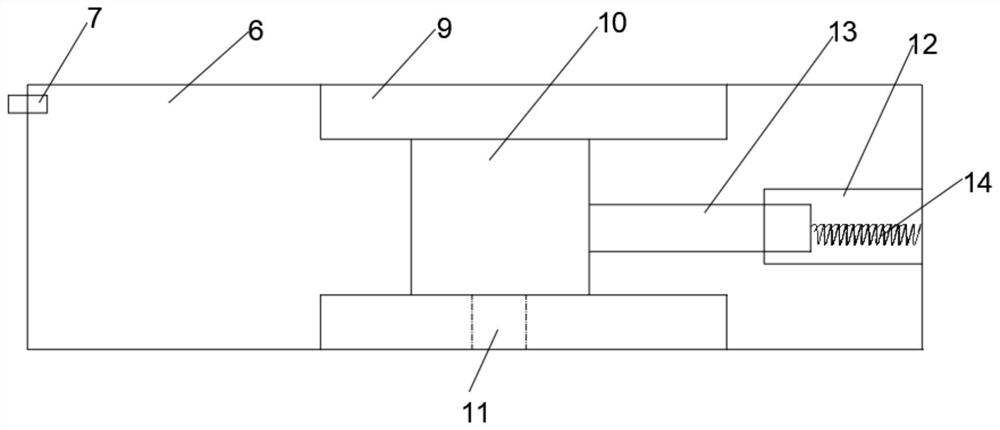

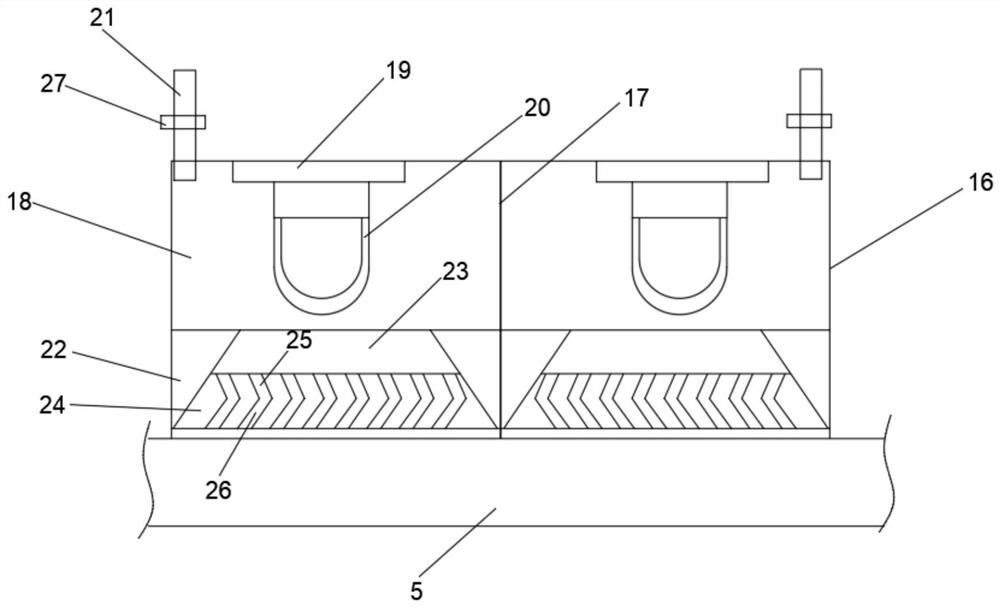

[0027] Such as Figure 1-Figure 4 As shown, the present invention provides a kind of SCR denitrification urea hydrolysis ammonia plant, comprising,

[0028] Urea storage and dissolving system 1, the urea storage and dissolving system 1 is used to store urea, and add water to the stored urea to dissolve;

[0029] Urea hydrolysis reaction system 2, the urea hydrolysis reaction system 2 can hydrolyze urea to generate mixed steam of ammonia, carbon dioxide and water;

[0030] A urea supply and metering system 3, the urea supply and metering system 3 is used to quantitatively transport the urea in the urea storage and dissolution system 1 to the urea hydrolysis reaction system 2;

[0031] Ammonia separation system 4, the ammonia separation system 4 communicates with the urea hydrolysis reaction system 2 through a connecting pipe 5, and the mixed steam generated by the urea hydrolysis reaction system 2 is transported to the In the ammonia gas separation system 4, the ammonia gas s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com