Defoaming heat-resistant conveying equipment for glass production and manufacturing

A conveying equipment and heat-resistant technology, applied in the field of glass production, can solve the problems of heat accumulation, poor heat-resistant effect of the bearing device, and inability to effectively release it, and achieve the effect of increasing the heat dissipation effect, increasing the cleaning effect, and increasing the effect of auxiliary air flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

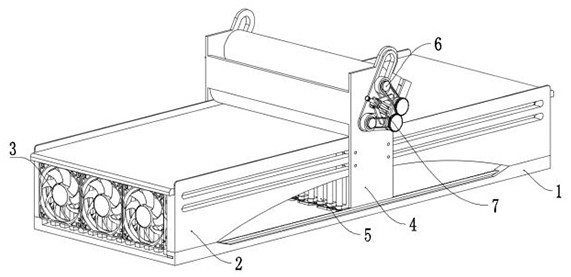

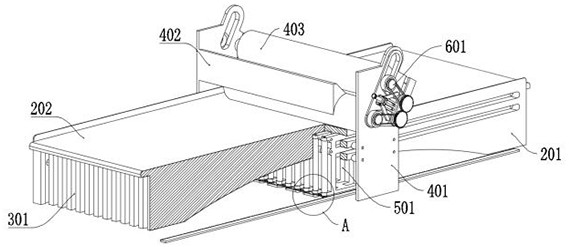

[0028] Example: as attached figure 1 to attach Figure 10 As shown: the present invention provides a defoaming and heat-resistant conveying equipment for glass production and manufacturing, including a base structure 1; 2 is equipped with a heat dissipation structure 3; the heat dissipation structure 3 includes: a heat dissipation frame 301, the heat dissipation frame 301 is a sheet structure, the heat dissipation frame 301 is arranged in an array, and an arc-shaped groove is opened at the bottom, and the arc-shaped shape of the heat dissipation frame 301 The groove matches the arc groove at the carrier frame 201, and the cooling frame 301 is fixed in the carrier frame 201. The cooling frame 301 of the carrier frame 201 is conducive to the heat transfer between the cooling frame 301 and the carrier frame 201. The cooling rack 301 arranged in an array increases the heat dissipation effect of the cooling rack 301; the cooling fan 302, the cooling fan 302 is installed at the lef...

no. 2 example

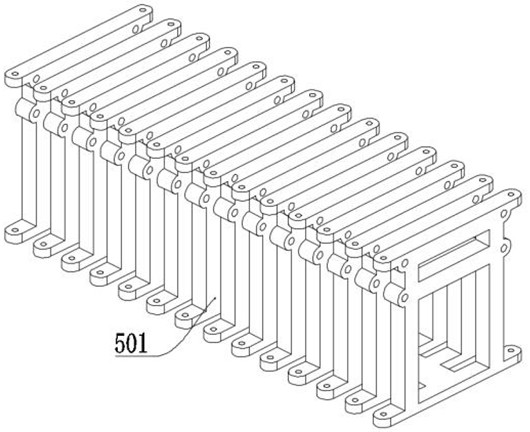

[0033] The second embodiment: the installation structure 4, the installation structure 4 is slidably installed on the bearing device 2, and the bottom of the installation structure 4 is fixed with a cleaning structure 5; wherein, the cleaning structure 5 includes: a bottom carriage 501, and the bottom carriage 501 is a frame structure , the bottom carriages 501 are arranged in an array structure, and the bottom carriages 501 arranged in an array are connected and fixed at the bottom, and the distance between each group of bottom carriages 501 matches the heat dissipation frame 301, and through the bottom carriages 501 that match the heat dissipation frame 301, Realize that the frame body of the bottom carriage 501 can slide on the bottom of the heat sink 301, the bottom carriage 501 is fixed on the installation plate 401, and realize the drive when the installation plate 401 moves through the bottom carriage 501 fixed on the installation plate 401. The bottom carriage 501 slide...

no. 3 example

[0036] The third embodiment: the transmission assembly 6, the transmission assembly 6 is arranged on the front and rear end outer walls of the cleaning structure 5, and the position of the transmission assembly 6 is provided with a sliding structure 7 at the same time.

[0037] Wherein, the transmission assembly 6 includes: a sliding plate 604, the sliding plate 604 is a round structure, the sliding plate 604 is slidably installed on the mounting plate 401, and by sliding the sliding plate 604 installed on the mounting plate 401, it is beneficial to press the pressure wheel 403 Convenience during adjustment; external gear 601, two groups of external gears 601 are arranged altogether, two groups of external gears 601 are rotatably installed on the outermost end of sliding plate 604, gear teeth are arranged on the outer wall of external gear 601, two groups of external gears 601 are mutual The meshing structure, by installing the external gear 601 on the outermost end of the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com