Track robot walking mechanism

A technology for orbital robots and walking mechanisms, applied in manipulators, mining devices, mining equipment, etc., can solve problems such as slippage, increased accident risk, poor equipment stability, etc., achieve good limit effect, improve operation stability and safety, The effect of stable running trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

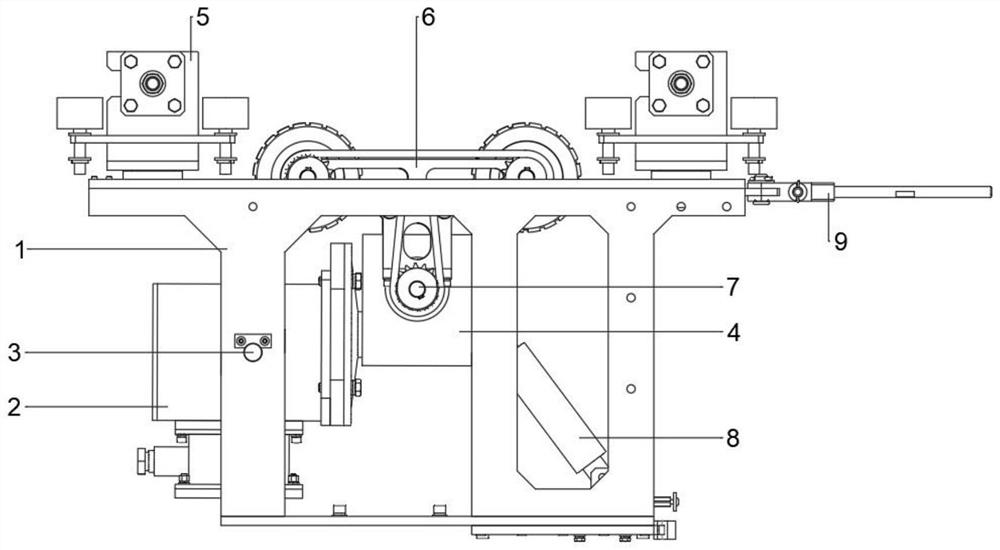

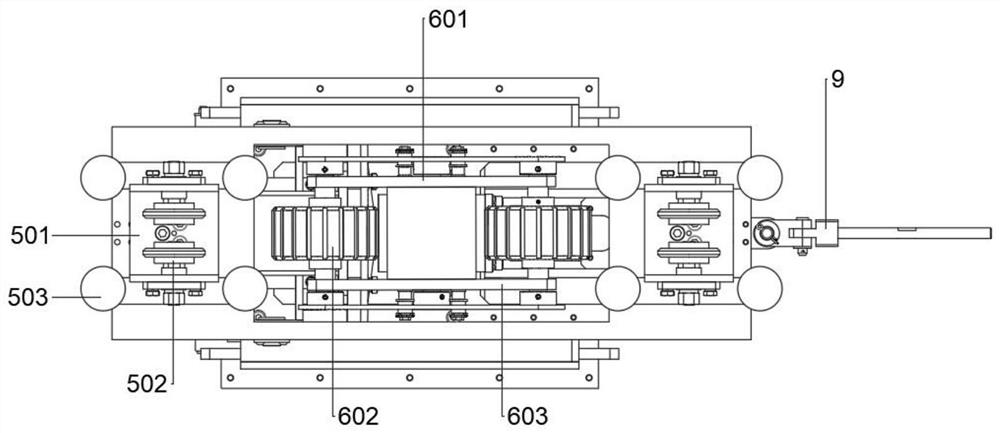

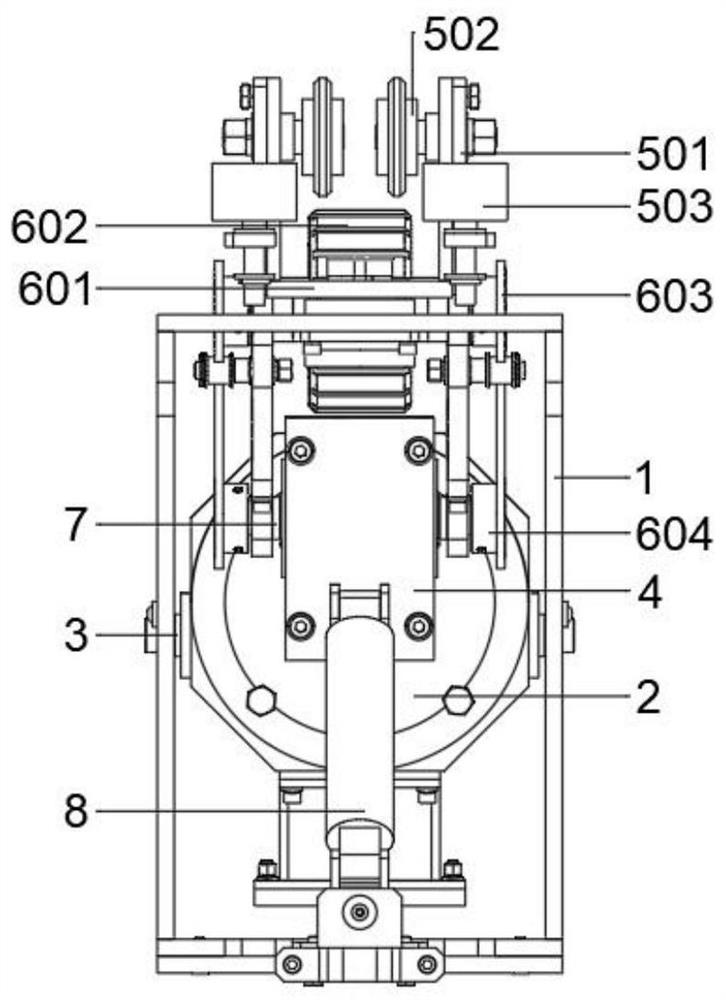

[0024] refer to Figure 1-Figure 5 , an orbital robot walking mechanism, combined with Figure 1 to Figure 4 As shown, it includes the main frame 1, the walking supporting wheel system 5 and the driving wheel system 6. The walking supporting wheel system 5 and the driving wheel system 6 are all assembled on the main frame 1, and the walking supporting wheel system 5 is clamped with the I-shaped steel track groove. The inner side of the drive wheel train 6 is closely attached to the surface of the I-shaped steel track. The track robot walking mechanism also includes a power assembly 2, an assembly shaft 3, a transmission assembly 4, an output shaft 7 of the transmission assembly, a compression spring 8 and a load suspension. Loading end 9, the assembly shaft 3 is fixedly installed on both sides of the power assembly 2, and the assembly shaft 3 is rotatably installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com