Cooking equipment and control method and disinfection application thereof

A technology of cooking equipment and control method, which is applied in the direction of disinfection, lighting and heating equipment, applications, etc., and can solve the problems that water vapor is easy to attach to the inner wall of the chamber to breed bacteria, and the cooking equipment has single purpose and low utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0032] Such as figure 1 As shown, this embodiment provides a control method for cooking equipment, wherein the cooking equipment has a chamber for heating food, a steam generating device for providing steam to the chamber, and a heating device for increasing the temperature of the chamber Specifically, the cooking device may be a commercially available microwave oven, steam oven, or other cooking device having a steam generating device and a heating device. Hereinafter, the cooking device is a microwave oven as an example for description.

[0033] A control method for cooking equipment includes the steps of:

[0034] a sterilizing step, releasing steam into the heated chamber to sterilize the contents of the chamber; and

[0035] In the drying step, the chamber is heated to dry the items.

[0036] In this embodiment, the use of existing cooking equipment for disinfection, on the one hand, solves the problem that the existing cooking equipment has a single purpose, is only us...

Embodiment approach 2

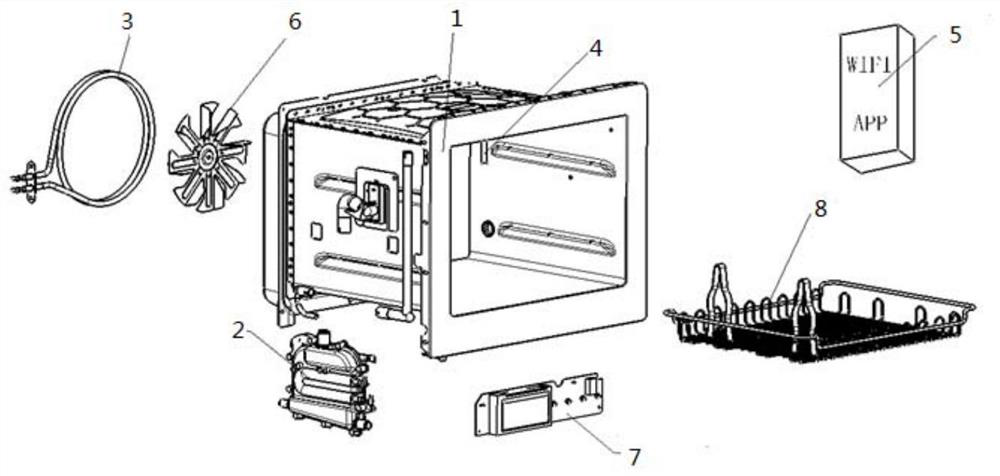

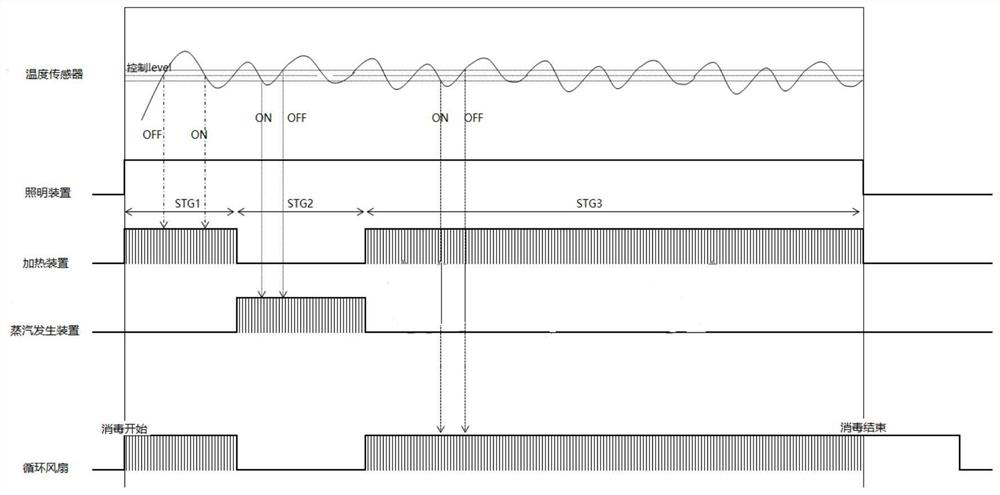

[0060] Such as figure 2 As shown, the present embodiment provides a cooking device 100 that can sterilize items by using the steam generated by the steam generating device it has. The cooking device 100 mainly includes: a chamber 1 for heating food, a steam generating device 2 for providing steam to the chamber 1, a heating device 3 for increasing the temperature of the chamber 1, and a temperature sensor for detecting the temperature of the chamber 1. A sensor 4 and a control unit 5 for controlling the operation of the cooking device 100 .

[0061] Wherein, the temperature sensor 4 can transmit the temperature information of the chamber 1 to the control unit 5, and the control unit 5 can issue commands based on the temperature information to control the operation of the cooking device.

[0062] Specifically, when the temperature sensor 4 detects that the temperature of the chamber 1 exceeds the current preset temperature, the control unit 5 can issue a corresponding instruc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com