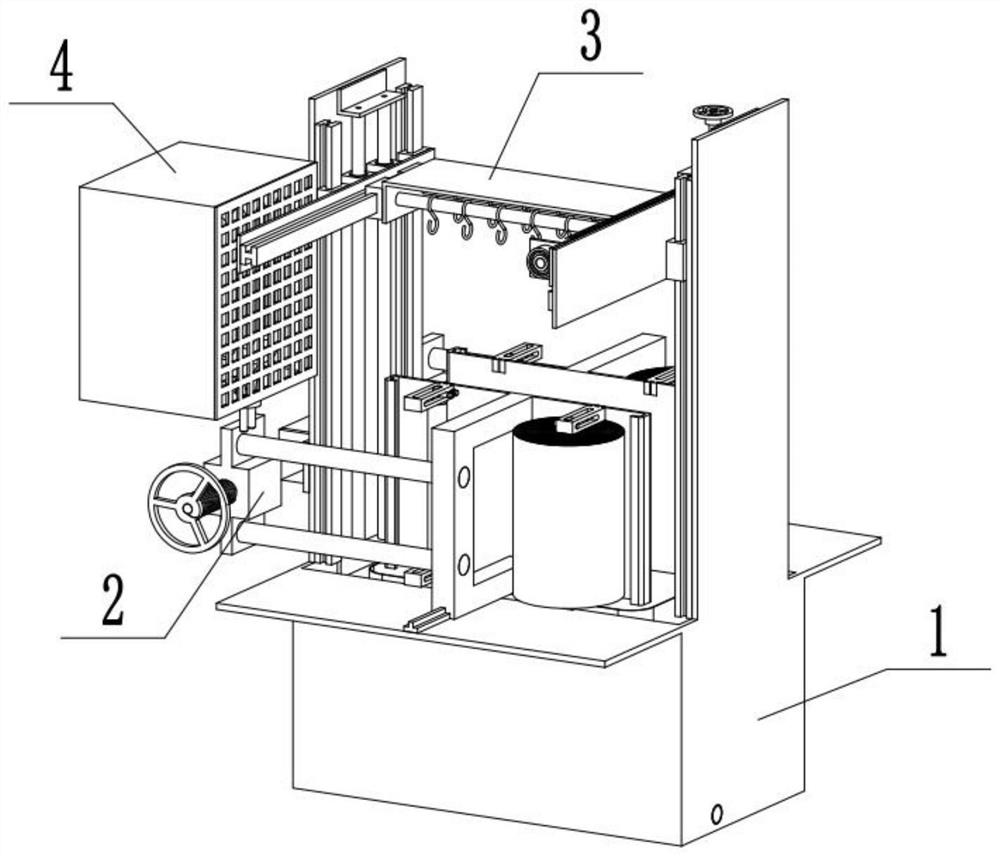

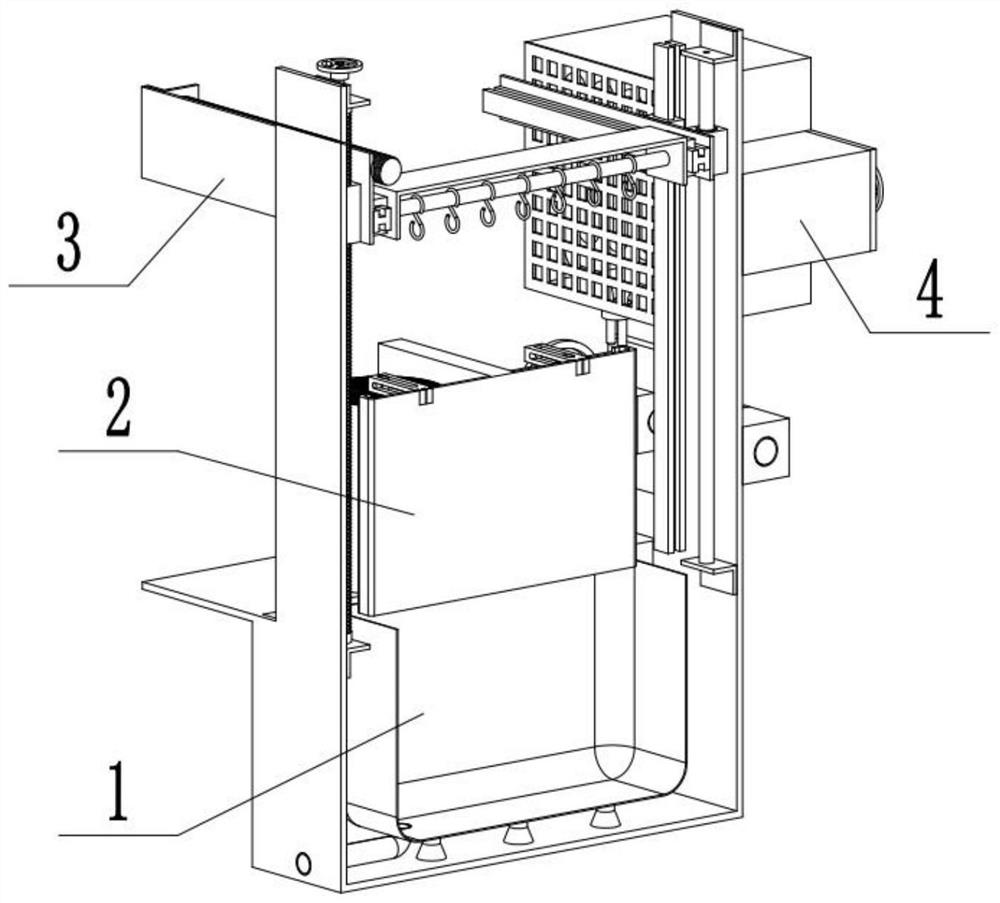

Disinfecting and drying equipment for medical apparatus and instruments

A technology for drying equipment and medical equipment, applied in the industrial field, can solve the problems of increasing the disinfection time, increasing the work efficiency, and the existence of water stains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

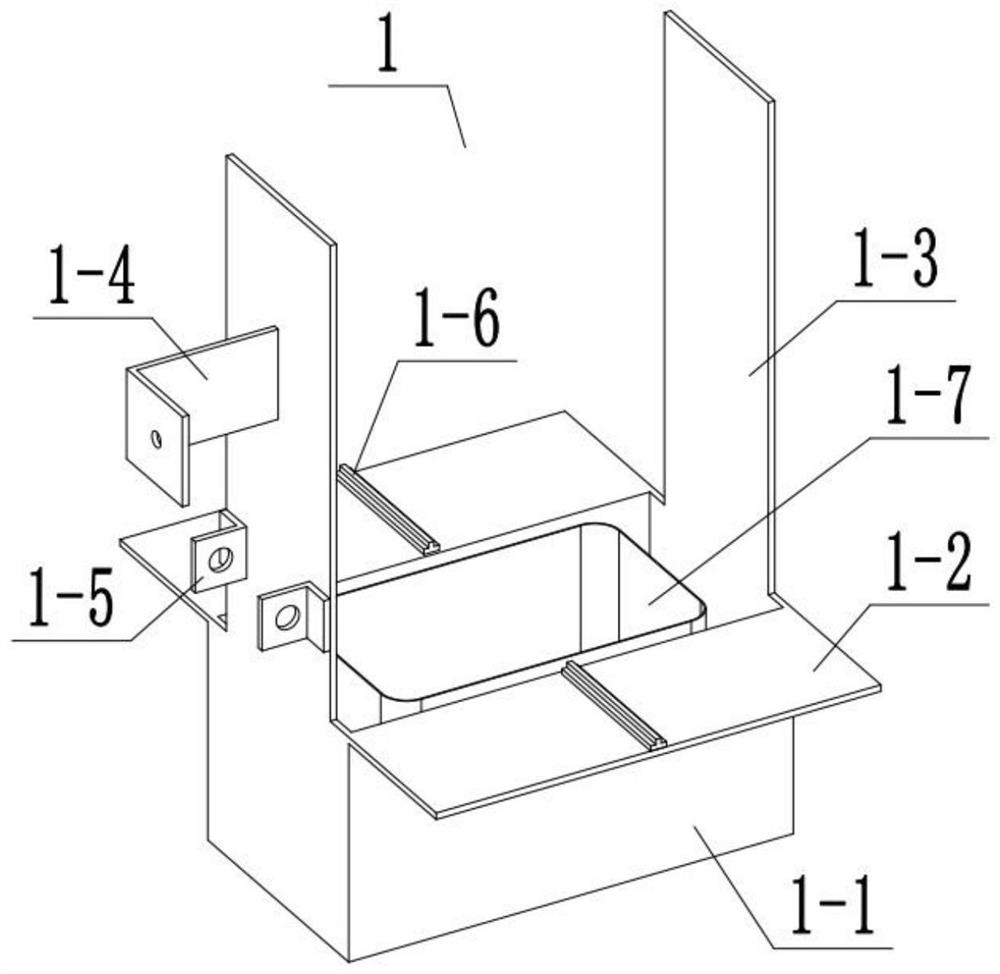

[0035] Move the medical device into the cleaning frame 1-7, and power on the ultrasonic converter 1-9 to achieve the cleaning effect. After cleaning, move the medical device up, then open the plug of the drain pipe 1-8, and put the After use, the disinfectant water is discharged through the drain pipe 1-8, and the disinfectant water is re-added during the next use.

specific Embodiment approach 2

[0036] The beginning of the drying cloth 2-15 is fixed on the drying cylinder 2-16 next to it by drying the face of the push plate 2-8, and at the same time, due to the effects of the drying spring A2-17 and the drying spring B2-18, the two A roller band wiping cloth 2-15 is stuck on the back side of wiping push plate 2-8 by frictional force, prevents wiping cloth 2-15 from moving left and right when wiping the water stains of medical equipment after disinfection, when wiping cloth 2 After -15 is adjusted, turn the drying handle 2-1 to drive the drying screw rod 2-2 to rotate. Since the two ends of the drying screw rod 2-2 are positive and negative threads respectively, the drying adjustment blocks 2-3 at both ends move toward each other At the same time, the drying connecting rod 2-6 drives the drying pushing rod 2-7 to move toward each other along the drying slide rail 1-6, so that the drying push plate 2-8 moves oppositely to the side of the sterilized medical device, and th...

specific Embodiment approach 3

[0037] Hang the medical equipment to be sterilized on the equipment fixing hook 3-3, then turn the front and rear adjustment handle 3-16 to drive the front and rear adjustment screw rods 3-11 to rotate, so that the front and rear adjustment wire sleeves 3-12 move along the front and rear adjustment screw rods 3- 11. Move back and forth, and drive the instrument fixing plate 3-1 to move back and forth at the same time. Since the instrument fixing hook 3-3 is fixed on the instrument fixing plate 3-1 through the instrument fixing rod 3-2, the medical instruments that need to be sterilized also move forward and backward at the same time. At the same time, due to the joint action of the adjustment slider A3-4 and the adjustment slide bar A3-5, the movement is easier and faster, and then the medical device is moved to the top of the cleaning frame 1-7, and then the up and down adjustment handle 3-23 is rotated to make it move up and down. Adjust the screw rod 3-24 to rotate, drive th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com