Rotary positioning bread board assembly optical collimator device

An optical collimation and breadboard technology, applied in optics, optical components, instruments, etc., can solve problems such as difficult to find light sources, affect assembly efficiency, and slow light adjustment speed, so as to facilitate optical assembly and improve efficiency , the effect of rapid value adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

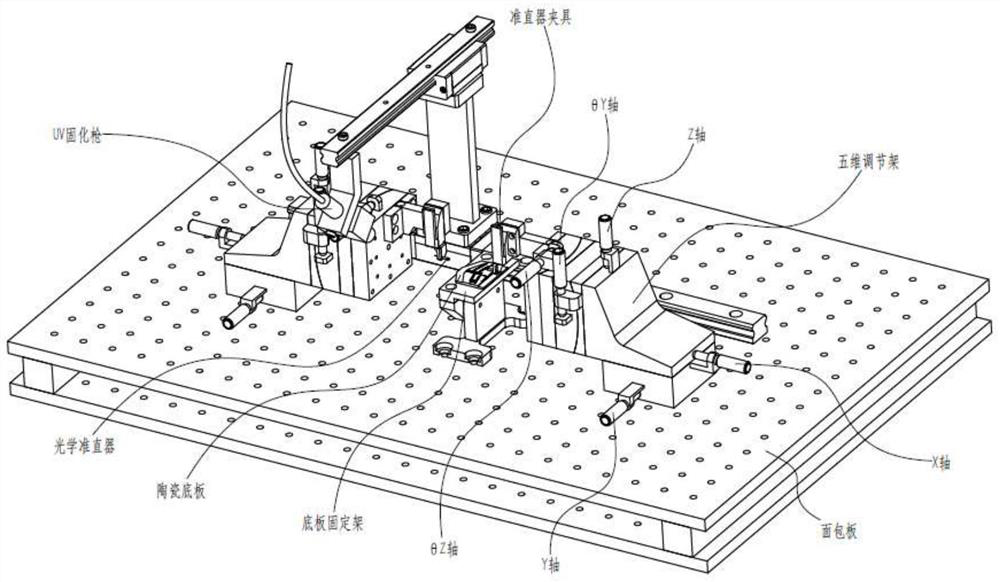

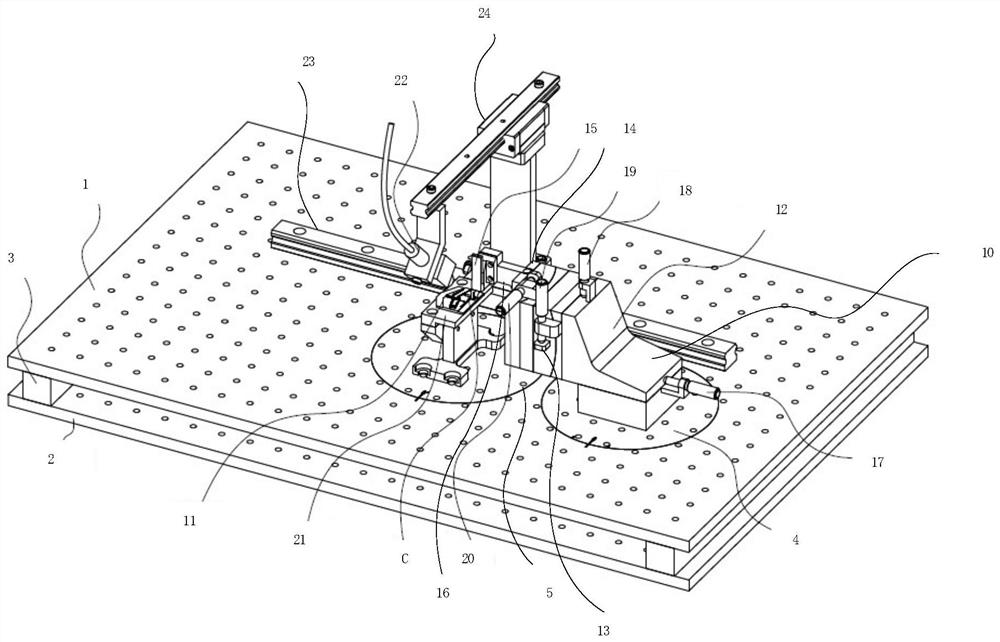

[0017] Such as Figure 2 to Figure 4 As shown, the embodiment of the present invention provides a device for assembling an optical collimator on a rotationally positioned breadboard, including: a rotationally positioned breadboard and an assembly device.

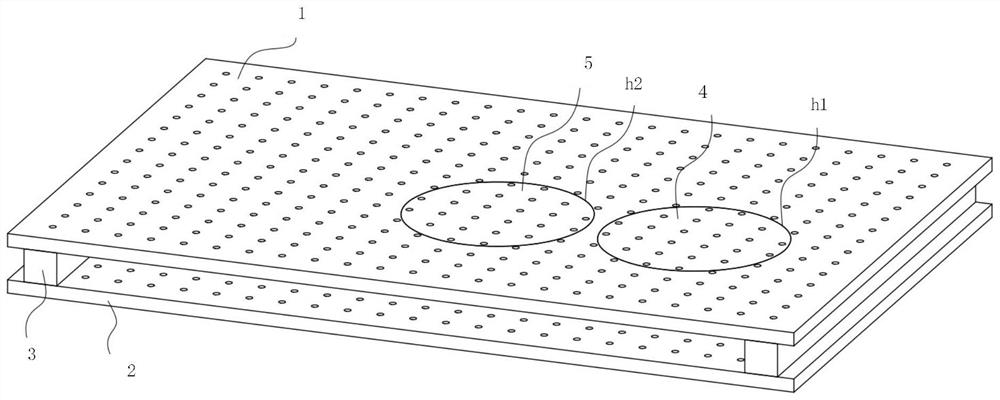

[0018] Wherein, the rotating positioning board includes an upper breadboard 1 and a lower breadboard 2 arranged at intervals, and the two ends of the upper breadboard 1 and the lower breadboard 2 are connected by a support block 3 . A fixing hole 301 may be formed on the supporting block 3, and a fixed connection between the upper breadboard 1 and the lower breadboard 2 is realized by screws. The upper breadboard 1 and the lower breadboard 2 are respectively provided with a plurality of through holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com