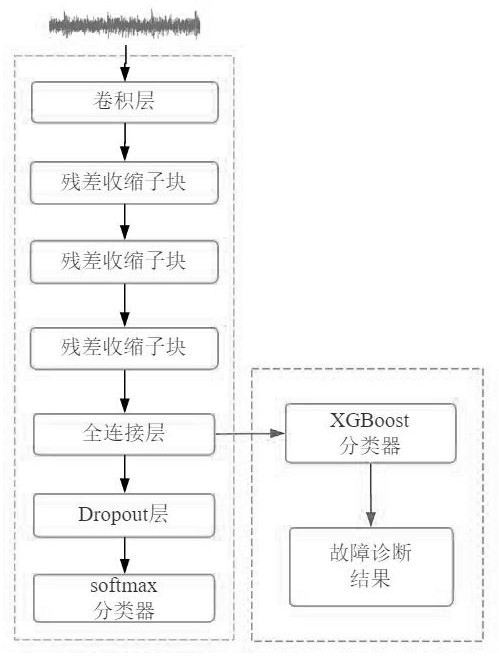

Industrial process performance evaluation method of mixed deep residual shrinkage network and XGBoost algorithm

An industrial process and network technology, applied in neural learning methods, biological neural network models, calculations, etc., can solve problems that affect diagnostic accuracy, softmax classifiers cannot further improve diagnostic accuracy, achieve good classification performance, and avoid model degradation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

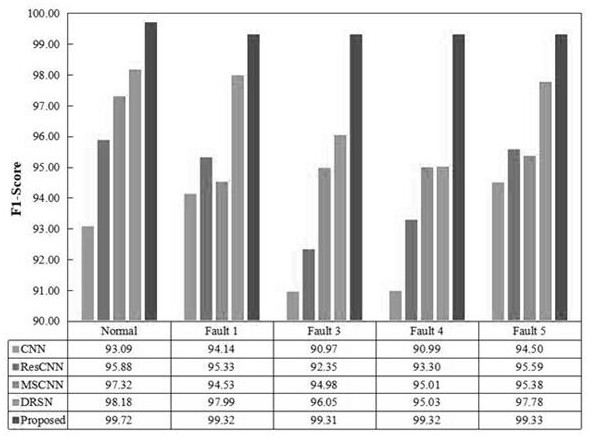

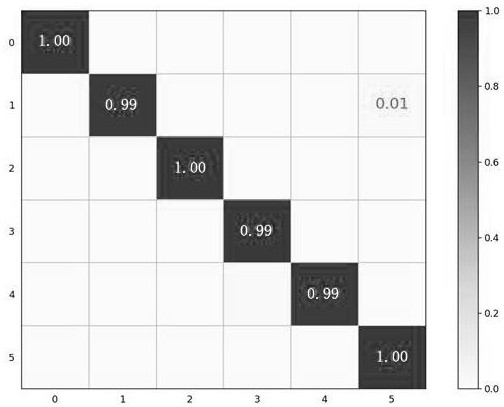

Examples

Embodiment

[0090] Industrial coking furnace is a typical industrial process system. It is a vertical tube heating furnace. It plays an irreplaceable role in the deep processing of chemical raw materials. Its fuel is generally high-pressure gas. When working, the gas enters the coking furnace from the north and south sides respectively, and the raw material residual oil is sent to the convection chamber of the coking furnace from the north and south sides to be preheated at about 330°C, and then sent to the bottom of the fractionation tower together, where it contacts with the oil and gas from the top of the coking furnace. Heat and mass transfer; during this process, the lighter components in the mixed oil evaporate and rise to the rectification section for separation, while the fraction above the wax oil in the raw material flows into the bottom of the tower together with the condensed components from the coke tower top oil gas. The bottom oil of the fractionation tower at about 360°C is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com