Aircraft turbomachine rotor comprising damping device

A technology for turbines and aircraft, applied in the direction of machines/engines, mechanical equipment, engine components, etc., to reduce weight, reduce wear, and improve air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

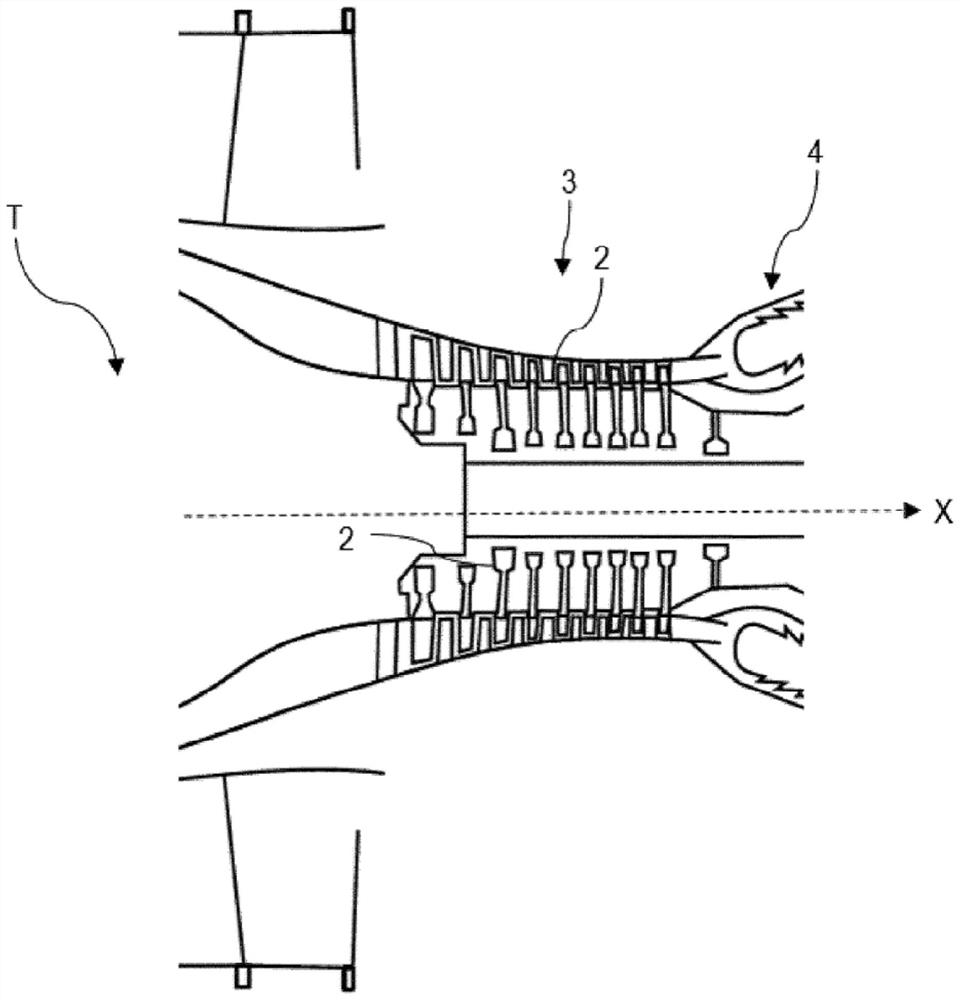

[0046] refer to figure 1 , which shows that the turbine T extends longitudinally along the axis X and is capable of driving the aircraft by causing the flow of air entering the turbine T to flow from upstream to downstream. In the following, the terms "upstream" and "downstream" are defined relative to an axis X oriented from upstream to downstream. Similarly, the terms "inner" and "outer" are defined with respect to the radial direction of the longitudinal axis X. As is known, the turbomachine T comprises a compressor 3 , a combustion chamber 4 and a turbine that drives the compressor 3 in rotation. The compressor 3 comprises one or more rotors 2 mounted about a longitudinal axis X to compress the gas flow flowing from upstream to downstream in the main duct of the turbine.

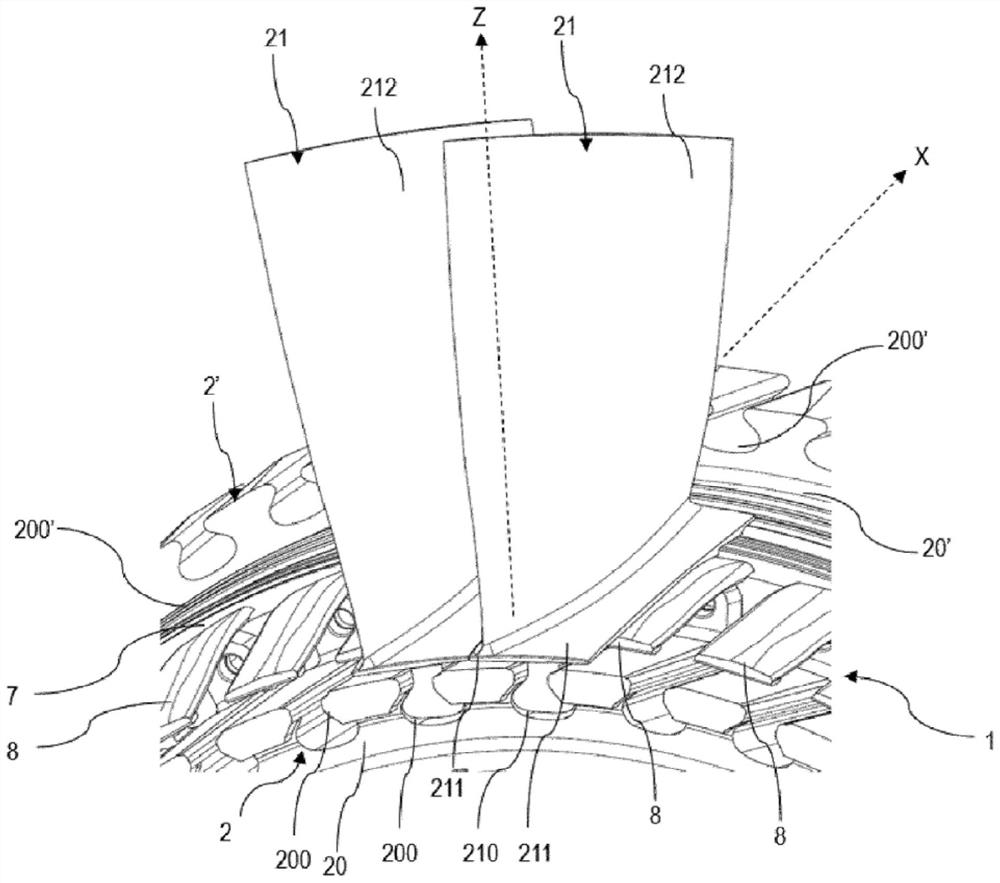

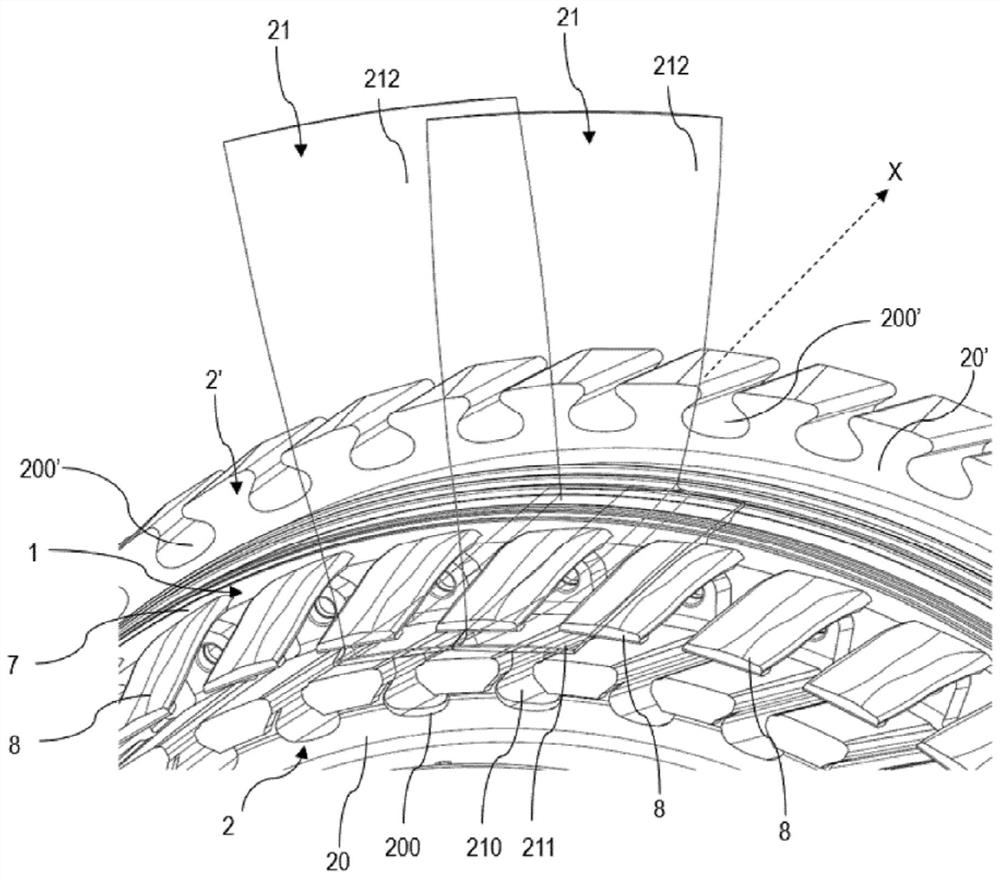

[0047] Such as figure 2 As shown, the rotor 2 includes a rotor disk 20 extending transversely with respect to the longitudinal axis X and a plurality of blades 21 , and the rotor disk 20 is integrall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com