Automatic processing equipment for kowkui tea

A technology of automatic processing and Houkui tea, which is applied in tea processing before extraction, etc., can solve the problem of low utilization rate of drying net space, achieve the effect of eliminating repeated feeding and leakage, ingenious structure, and convenient observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

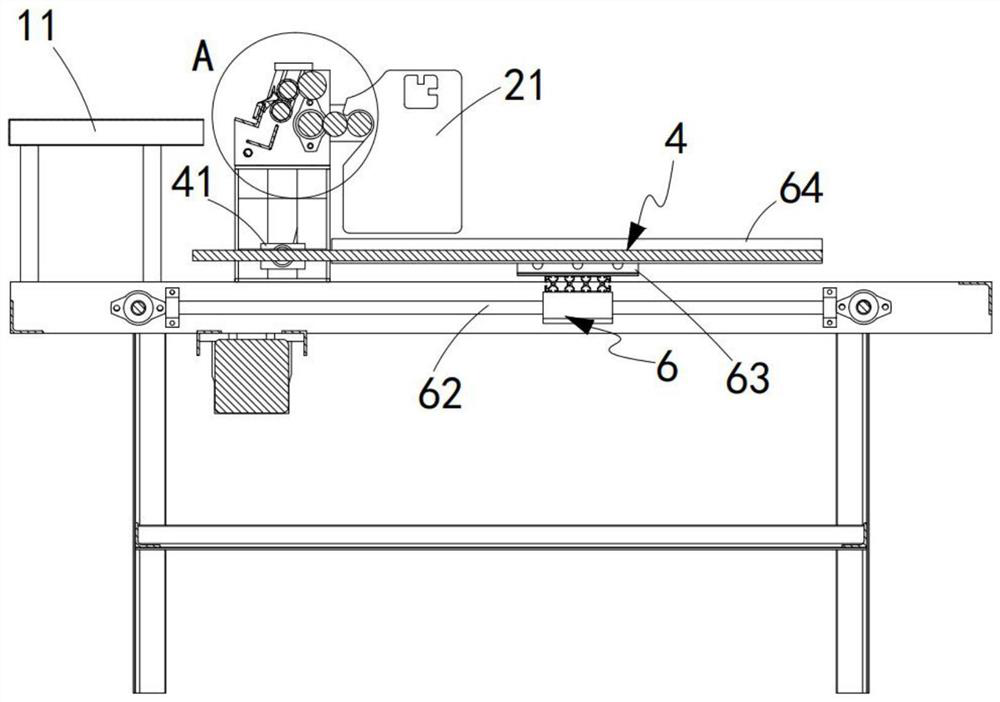

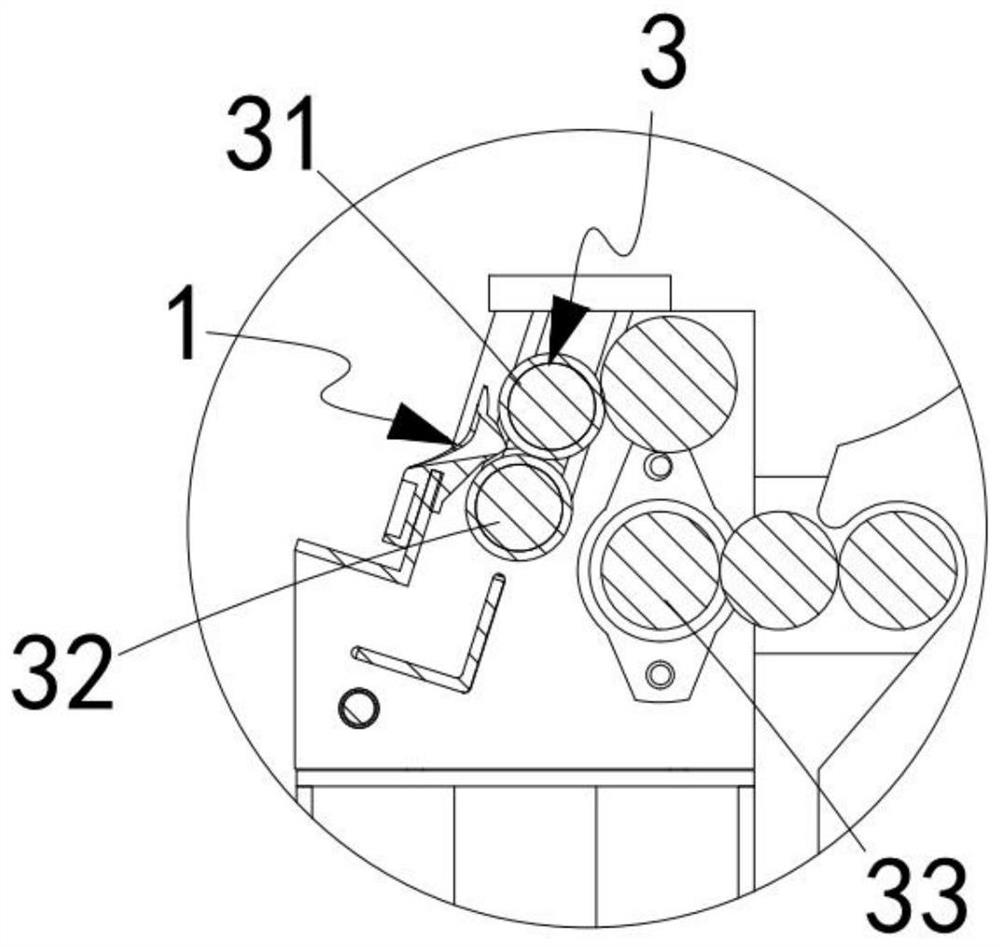

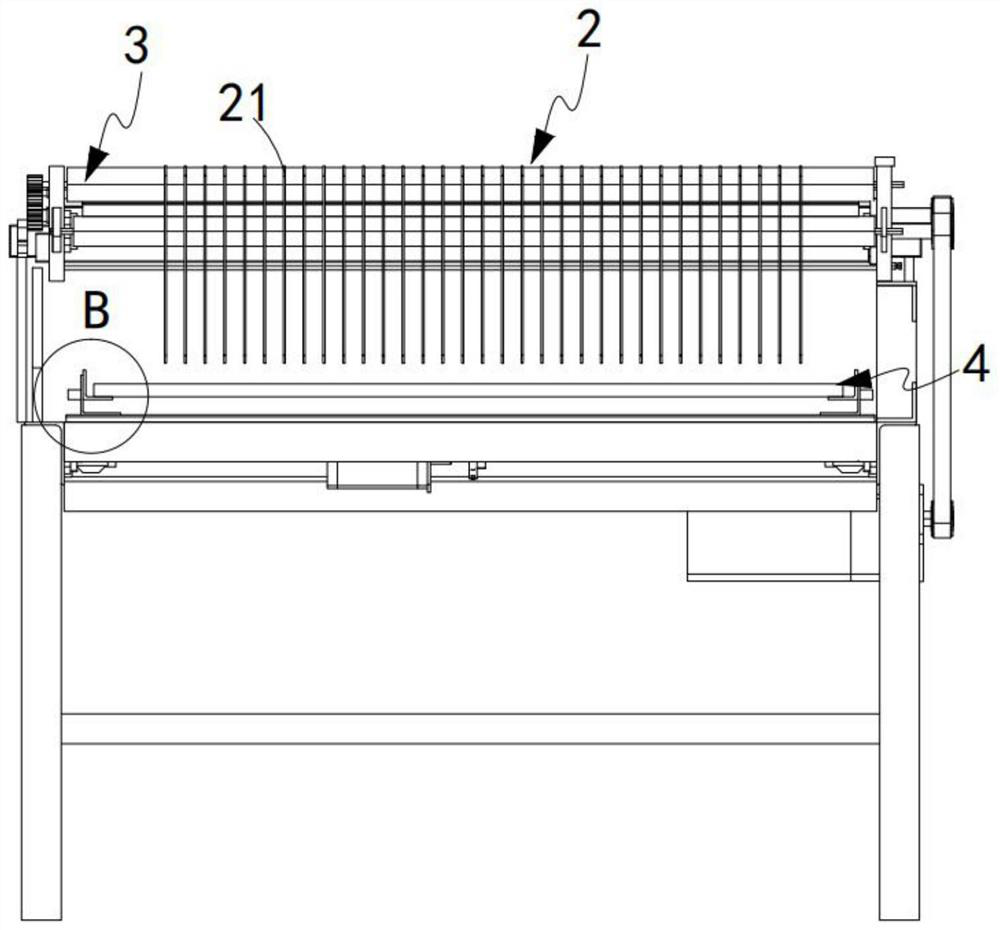

[0042] Such as Figure 1 to Figure 9 As shown, an automatic processing equipment for Houkui tea, including a material guide nozzle 1, a blanking channel 2 corresponding to the material guide nozzle 1, and a rolling roller group 3 located between the material guide nozzle 1 and the blanking channel 2 And drying net 4,

[0043] When the drying net 4 is conveyed intermittently along the setting direction of the blanking channel 2, the drying net 4 moves along a horizontal direction perpendicular to the setting direction of the blanking channel 2, and the drying net 4 is installed on The conveying mechanism 6 below it drives to carry out conveying.

[0044] Further, the drying net 4 is pushed and moved along the horizontal direction perpendicular to the setting direction of the blanking channel 2 through the pushers 41 arranged on both sides of the conveying path. below.

[0045] Furthermore, the relationship between the pushing distance S of the pusher 41 and the width L of th...

Embodiment 2

[0054] Figure 10 It is a schematic structural view of Embodiment 2 of a kind of Houkui tea automatic processing equipment of the present invention; as Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0055] As shown in the figure, when the drying net 4 is conveyed intermittently along the setting direction of the blanking channel 2, the material guide nozzle 1 moves along the horizontal direction perpendicular to the setting direction of the blanking channel 2, and the The blanking channel 2 moves synchronously with the material guide nozzle 1.

[0056] Wherein, the material guide nozzle 1 is pushed and moved along the horizontal direction perpendicular to the ...

Embodiment 3

[0059] Figure 11 It is a schematic structural view of Embodiment 3 of a kind of Houkui tea automatic processing equipment of the present invention; as Figure 11 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. This embodiment three and figure 1 The difference of the shown embodiment one is:

[0060] Such as Figure 11 As shown, the material feeding nozzle 1 is provided with a feeding monitoring system 5, and the feeding monitoring system 5 is used to monitor whether monkey Kui tea leaves are put into the feeding nozzle 1.

[0061] Further, the feeding monitoring system 5 includes:

[0062] Inductor 51, the inductor 51 is arranged in the corresponding material guide nozzle 1, and the sensor 51 is used to sense the monkey Kui tea leaves put into the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com