High-efficiency large-volume intelligent waste transport vehicle achieving automatic classification

An automatic classification and large-volume technology, which is applied in the direction of garbage storage, transportation and packaging, etc., can solve the problems of reducing the space utilization rate of garbage bins, achieve the effects of reducing labor intensity and potential safety hazards, improving efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

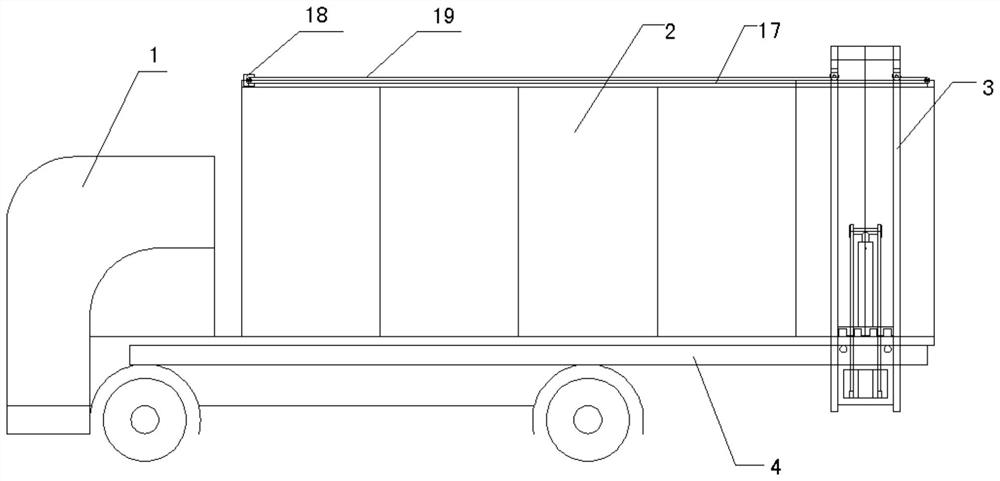

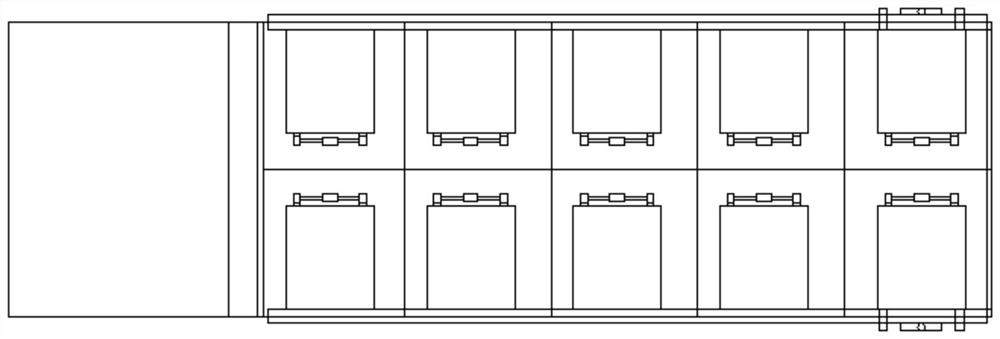

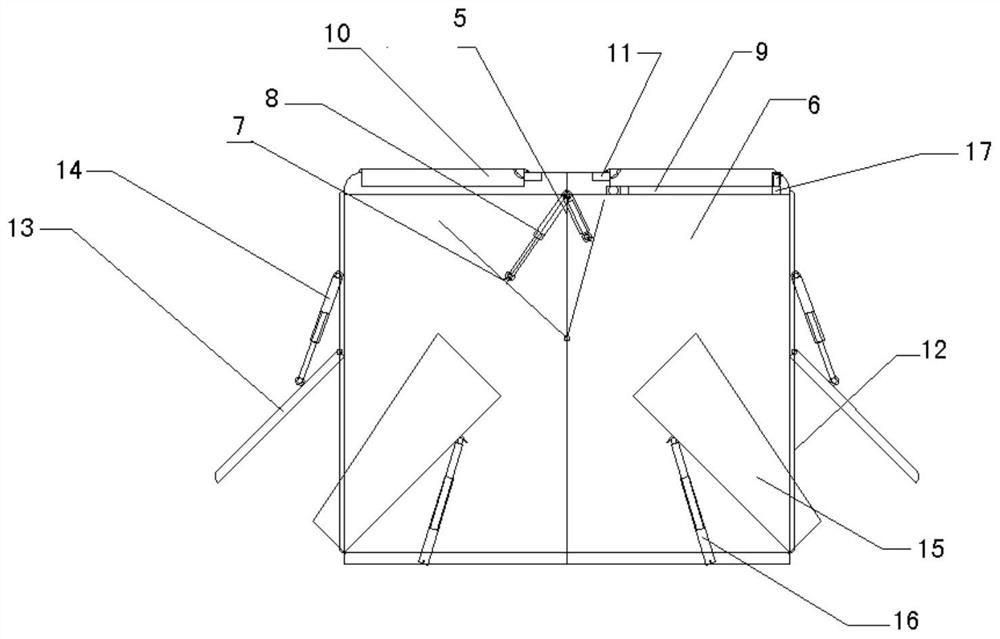

[0025] This embodiment provides a high-efficiency and large-capacity intelligent garbage automatic sorting transport vehicle, the structure of which is as follows: Figure 1-4 As shown, it includes a transport vehicle body 1, a plurality of garbage bins 2 and a garbage can hoist 3, and a plurality of garbage bins are neatly arranged and fixed on the transport vehicle body, and the exterior color of each garbage can is different. The side is provided with a guide rail 4 for the movement of the trash can hoist, and the trash can hoist is slidably connected to the guide rail, and at the same time, a runway 17 for rolling the top rollers of the trash can hoist is provided on the top of each trash can, and in the runway Drive motor 18 is arranged on the end, and this drive motor is connected with roller transmission by belt 19, and dustbin 2 interior is provided with dividing plate 5, and this dustbin interior is divided into two rubbish storage bins 6, two of each dustbin The outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com