Dish washing machine and disinfection method thereof

A disinfection method and technology for dishwashers, applied in chemical instruments and methods, washing machines/washing machines for tableware, parts of washing machines/rinsing and washing machines for tableware, etc., can solve the problem of easy generation of bacteria or odors in dishwashers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

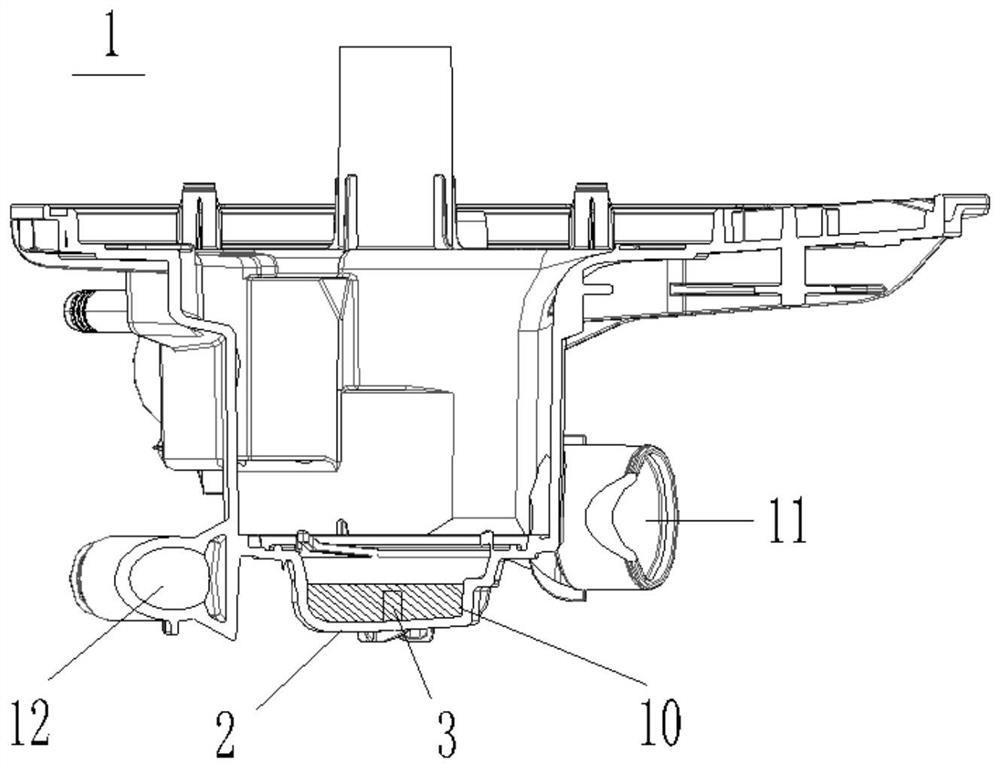

[0036] This embodiment provides a dishwasher, such as Figure 1-Figure 5 shown, including:

[0037] Inner tank 15, the cleaning operation is carried out inside;

[0038] A water cup 1 is provided with a water inlet 11 and a water outlet 12;

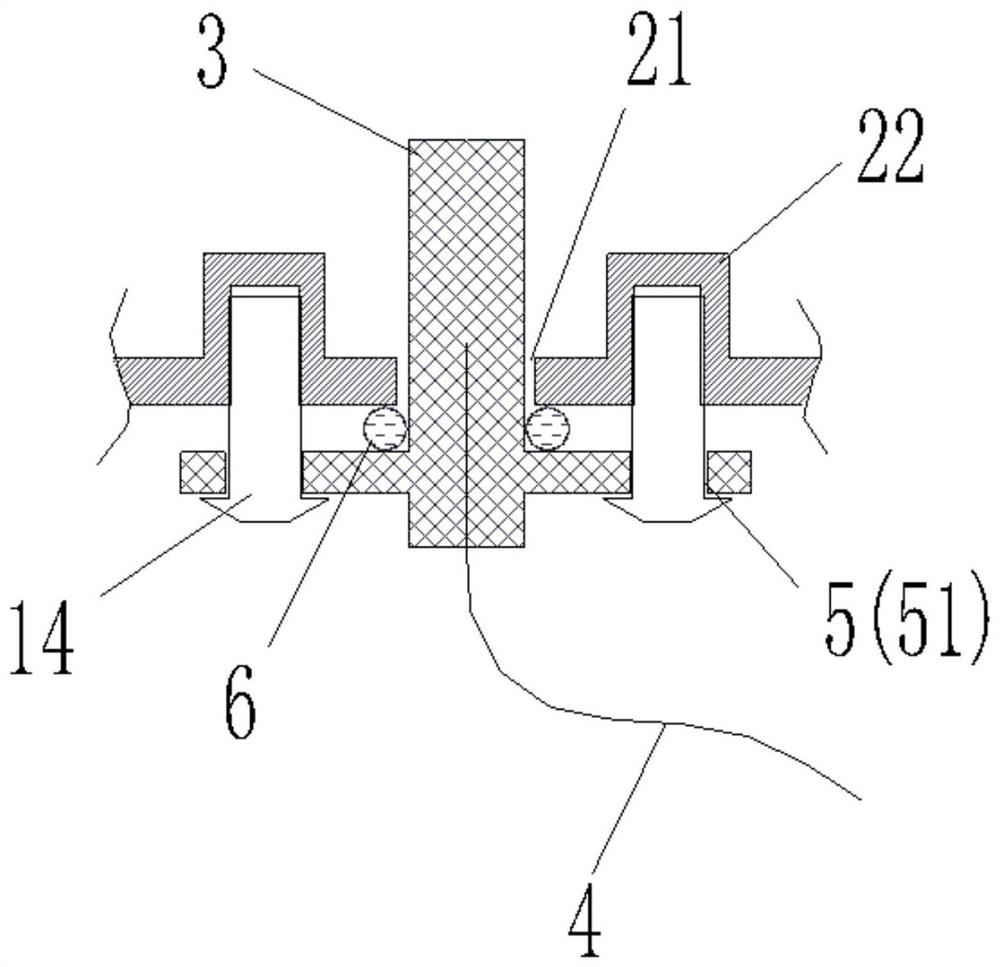

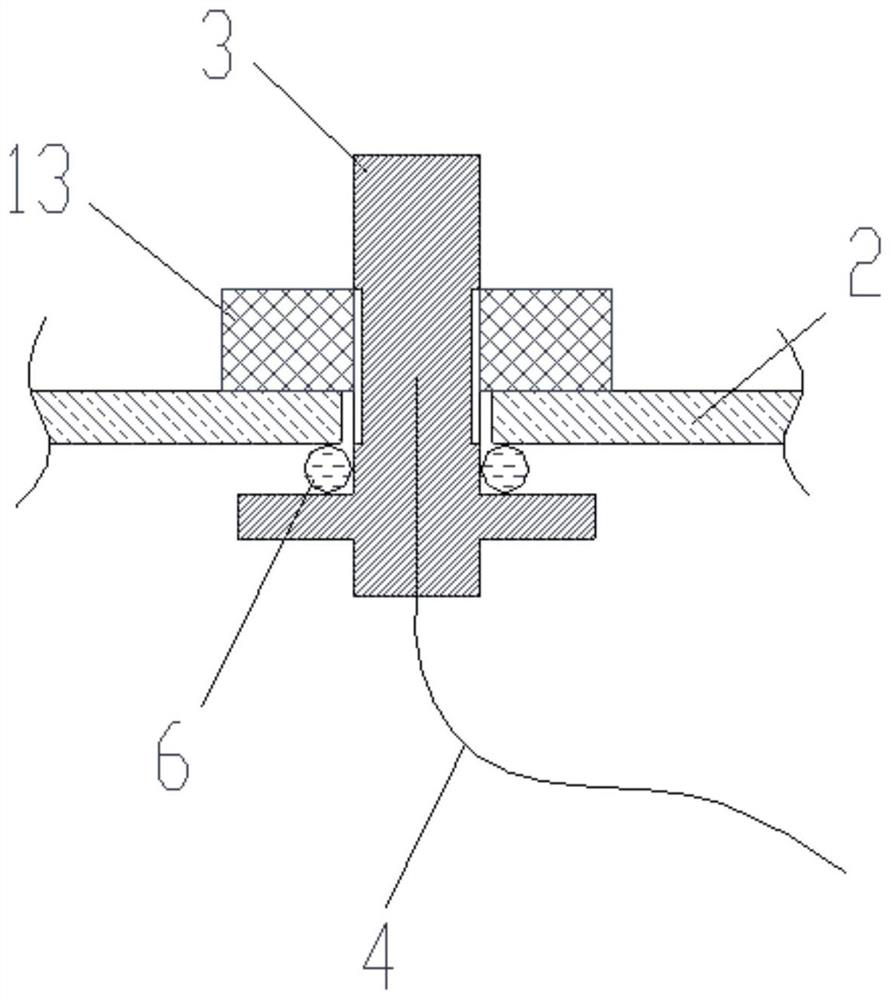

[0039] A low-lying water storage part 2, the low-lying water storage part 2 is provided with a connection port 21;

[0040] Specifically, as figure 1 As shown, the ground of the low-lying water storage part 2 will be lower than the plane where the drainage pump is located, so that after the drainage pump completes the drainage action, there will be a certain amount of residual water inside the low-lying water storage part 2. After a long period of storage, it will lead to bacterial growth and produce peculiar smell.

[0041] A plasma generating device is connected to the water cup 1, and the plasma generating device includes:

[0042] The electrode 3 enters the interior of the low-lying water storage part 2 through the connection por...

Embodiment 2

[0061] This embodiment also provides a dishwasher disinfection method, the dishwasher is provided with a water cup, the dishwasher is provided with an air intake fan, and a low-lying water storage part is provided on it; the plasma generating device is provided on the In the low-lying water storage department.

[0062] In the present embodiment, described disinfection method comprises the following steps:

[0063] Obtain the drying completion signal of the dishwasher;

[0064] Specifically, after finishing the cleaning operation of the dishes, in order to ensure the drying of the inside of the dishwasher, the air intake fan is started to ventilate the inside of the dishwasher. However, the ventilation operation is difficult to remove all the moisture inside, so that a certain amount of residual water still remains in the low-lying water storage part;

[0065] In this embodiment, after obtaining the signal that the dishwasher is finished drying, it further includes: the step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com